PH-sensitive release-type corrosion inhibition anti-rust packing and preparation and synthesis methods thereof

A sensitive and corrosion-inhibiting technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of complex preparation methods, achieve the effects of simple preparation methods, wide sources of raw materials, and improved dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

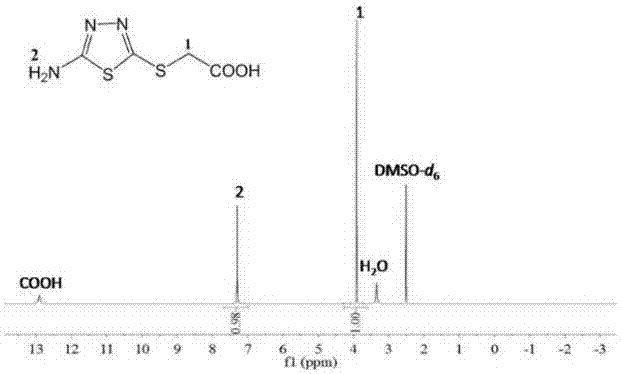

[0056] Add 0.1 mol of 5-amino-1,3,4-thiadiazole-2-thiol (AMT) into a 250 mL three-necked flask, and slowly add 0.2 mol of NaOH aqueous solution dropwise under magnetic stirring until AMT is completely dissolved. Slowly add chloroacetic acid aqueous solution containing 0.1 mol chloroacetic acid dropwise at room temperature, and the dropwise addition is completed within 30 minutes. The reaction was carried out at room temperature for 3 h, and the progress of the reaction was detected by thin-layer chromatography. After the reaction is completed, dilute sulfuric acid is added dropwise to the reaction solution, and a light yellow solid precipitates out, which is filtered by suction, washed repeatedly with water and ethanol, and dried for 10 hours to obtain solid 5-amino-1,3,4-thiadiazole- 2-thioacetic acid;

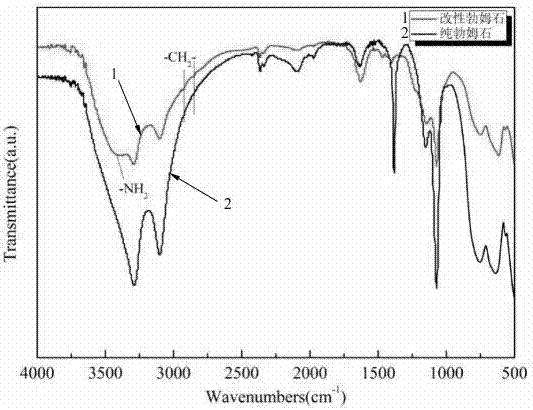

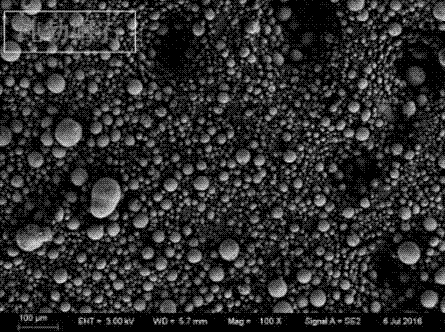

[0057] Add 0.5g boehmite to a 250mL three-necked flask containing 100mL N,N-dimethylformamide, and after ultrasonic dispersion for 30min, add 0.01mol of the above-prepared 5...

Embodiment 2

[0059] Add 0.15 mol of 5-amino-1,3,4-thiadiazole-2-thiol (AMT) into a 250 mL three-necked flask, and slowly add 0.3 mol of NaOH aqueous solution dropwise under magnetic stirring until AMT is completely dissolved. Slowly add chloroacetic acid aqueous solution containing 0.15 mol chloroacetic acid dropwise at room temperature, and the dropwise addition is completed within 30 minutes. And react at 50° C. for 4 h, and detect the progress of the reaction by thin-layer chromatography. After the reaction is completed, dilute sulfuric acid is added dropwise to the reaction solution, and a light yellow solid precipitates out, which is filtered by suction, washed repeatedly with water and ethanol, and dried for 10 hours to obtain solid 5-amino-1,3,4-thiadiazole- 2-thioacetic acid;

[0060] Add 1.0g boehmite to a 250mL three-necked flask containing 200mL N,N-dimethylformamide, and after ultrasonic dispersion for 30min, add 0.02mol of the above-prepared 5-amino-1,3,4-thiadiazole-2- Thio...

Embodiment 3

[0062] Add 0.2 mol of 5-amino-1,3,4-thiadiazole-2-thiol (AMT) into a 250 mL three-necked flask, and slowly add 0.4 mol of NaOH aqueous solution dropwise under magnetic stirring until AMT is completely dissolved. Slowly add an aqueous solution of chloroacetic acid containing 0.2 mol of chloroacetic acid dropwise at room temperature, and the dropwise addition is completed within 30 minutes. And react at 80° C. for 3 h, and detect the progress of the reaction by thin-layer chromatography. After the reaction is completed, dilute sulfuric acid is added dropwise to the reaction solution, and a light yellow solid precipitates out, which is filtered by suction, washed repeatedly with water and ethanol, and dried for 10 hours to obtain solid 5-amino-1,3,4-thiadiazole- 2-thioacetic acid;

[0063] Add 0.5g boehmite to a 250mL three-necked flask containing 100mL N,N-dimethylformamide, and after ultrasonic dispersion for 30min, add 0.01mol of the above-prepared 5-amino-1,3,4-thiadiazole-2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com