Method for preparing micron-order nickel-based high-temperature alloy powder transmission electron microscope film sample

A nickel-based superalloy, transmission electron microscope technology, which is applied in the preparation, sampling, measuring device and other directions of test samples, can solve the problems of long time consumption, poor coating quality, poor compatibility between copper and nickel powder, etc. Short time, good coating quality, good embedding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] GH96 nickel-based superalloy powder (mass percentage of alloy: Cr: 16.10, Co: 12.92, W: 4.0, Mo: 4.0, Ti: 3.72, Ni: Bal.) transmission electron microscope film with a particle size of 63-75 μm Sample preparation method, specific steps are as follows:

[0027] (1) Prepare the electroplating solution, add 1g of micron-grade GH96 nickel-based superalloy powder into the electroplating solution, and use mechanical stirring to suspend the nickel-based superalloy powder particles to obtain a suspension; the composition of the electroplating solution is: NiSO 4 7H2O 150g, NaCl 10g, H 3 BO 3 35g, Na 2 SO 4 120g, sodium lauryl sulfate 0.1g, add deionized water to 1L.

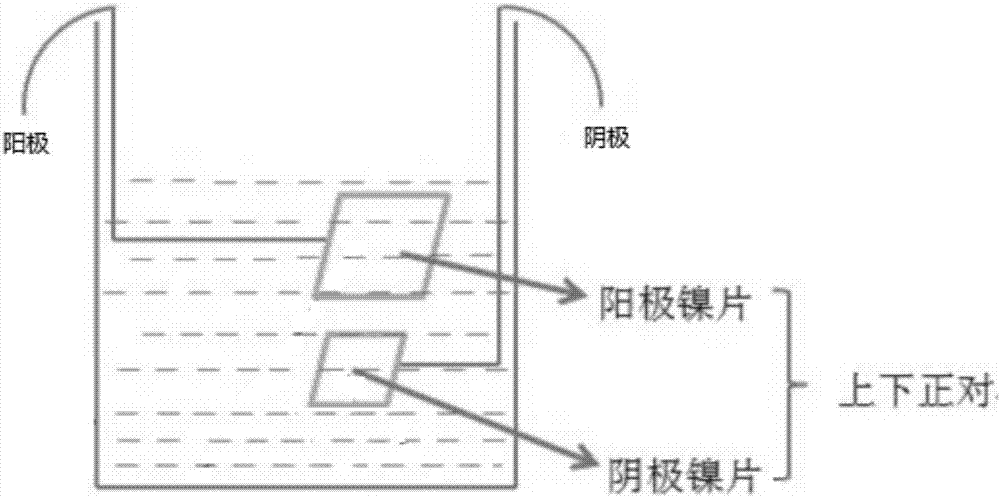

[0028] (2) Put the cathode nickel sheet and the anode nickel sheet into the suspension obtained in step (1) in the manner that the cathode nickel sheet is down and the anode nickel sheet is facing up and down (its structural representation is as follows: figure 1 shown), the nickel-based superalloy powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com