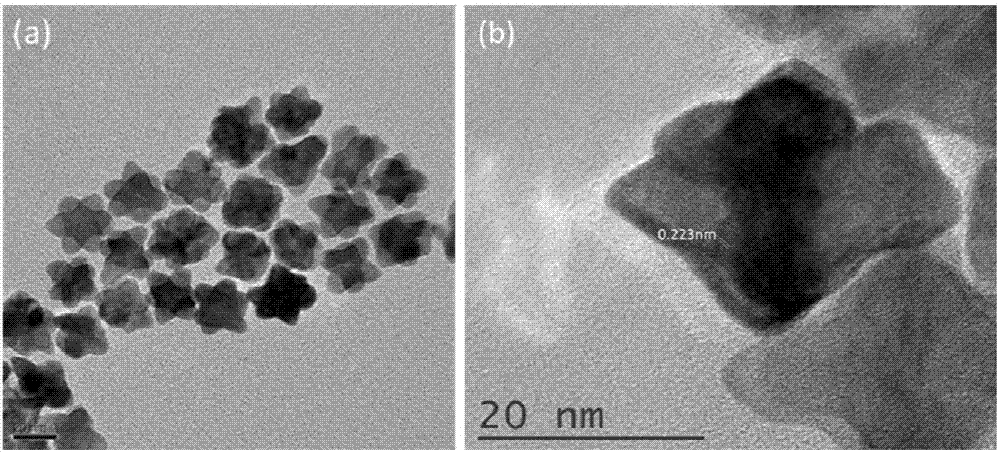

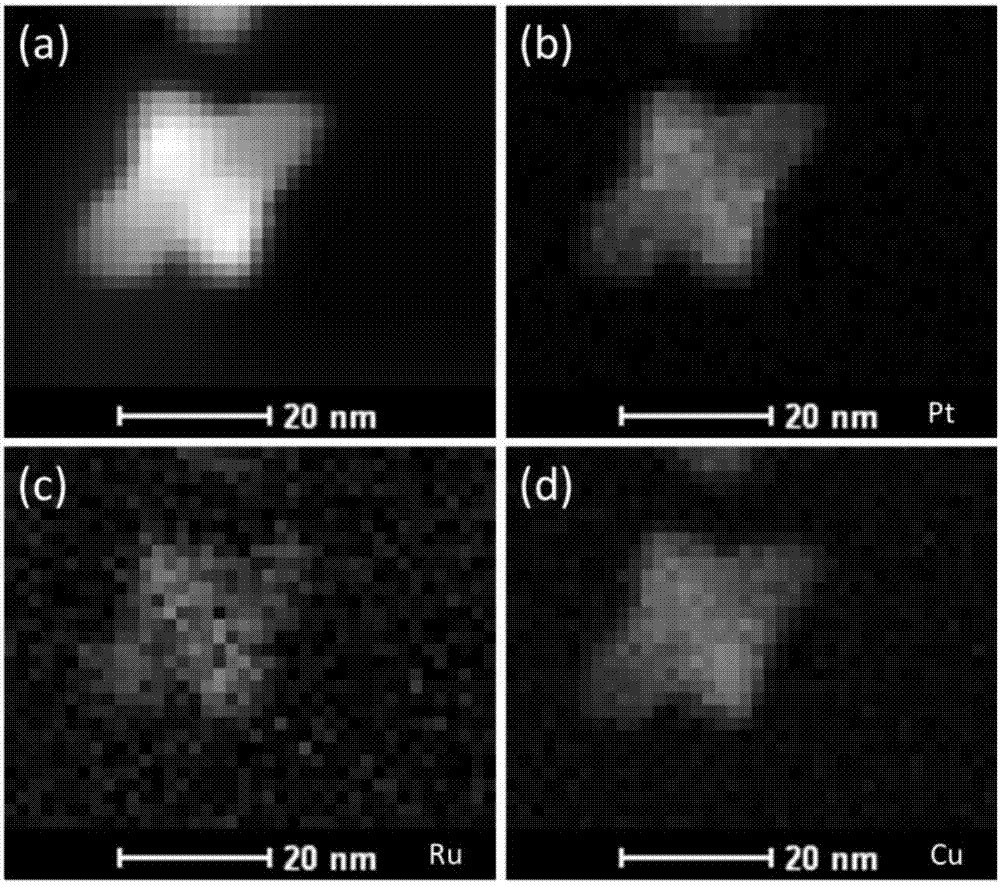

Petal-shaped Cu doped PtRu alloy catalyst and preparation method thereof

An alloy catalyst, petal-shaped technology, applied in the field of petal-shaped Cu-doped PtRu alloy catalyst and its preparation, can solve the problems of catalyst corrosion, high cost of catalyst application, depth of research and lack of application, etc., to achieve easy catalysis, high-quality methanol Oxidation performance, easy methanol oxidation reaction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] 1) Put 7.2mg of copper acetate, 5mL of oleylamine, 73mg of CTAB and 60mg of glucose into a 100mL eggplant-shaped reaction bottle with a branched mouth and ultrasonically mix them evenly, assemble the instrument, and vacuumize for 10 minutes;

[0044] 2) React the mixed liquid obtained in step 1) at a high temperature of 270° C. for 0.5 h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0045] 3) Put 20.4mg of platinum acetylacetonate, 4mg of ruthenium acetylacetonate and 10mL of oleylamine in a beaker and mix them uniformly by ultrasonic, add to the product obtained in step 2), and stir evenly with magnetic force;

[0046] 4) React the mixed liquid obtained in step 3) at a high temperature of 320° C. for 1 h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0047] 5) The obtained product was washed with a mixture of toluene and methanol at a ratio of 2:1 and ethanol for more than 3 times, and dried...

Embodiment 2

[0055] 1) Put 5mg of copper acetate, 10mL of oleylamine, 30mg of CTAB and 60mg of glucose in a 100mL eggplant-shaped reaction bottle with a branched mouth and ultrasonically mix them evenly, assemble the instrument, and vacuumize for 10 minutes;

[0056] 2) React the mixed liquid obtained in step 1) at a high temperature of 270° C. for 0.5 h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0057] 3) Put 10.2 mg of platinum acetylacetonate, 7 mg of ruthenium acetylacetonate and 10 mL of oleylamine in a beaker and ultrasonically mix them uniformly, add to the product obtained in step 2), and stir evenly with magnetic force;

[0058] 4) React the mixed liquid obtained in step 3) at a high temperature of 300° C. for 0.5 h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0059] 5) The obtained product was washed with a mixture of toluene and methanol at a ratio of 1:1 and ethanol for more than 3 times, and dr...

Embodiment 3

[0062] 1) Put 7.2mg of copper acetate, 5mL of oleylamine, 60mg of CTAB and 60mg of glucose in a 100mL eggplant-shaped reaction bottle with a branched mouth and ultrasonically mix them evenly, assemble the instrument, and vacuumize for 15 minutes;

[0063] 2) React the mixed liquid obtained in step 1) at a high temperature of 270° C. for 0.5 h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0064] 3) Put 20.4mg of platinum acetylacetonate, 4mg of ruthenium acetylacetonate and 10mL of oleylamine in a beaker and mix them uniformly by ultrasonic, add to the product obtained in step 2), and stir evenly with magnetic force;

[0065] 4) React the mixed solution obtained in step 3) at a high temperature of 270°C for 0.5h under CO atmosphere and magnetic stirring conditions, and cool to room temperature;

[0066] 5) The obtained product was washed with a mixture of toluene and methanol at a ratio of 2:1 and ethanol for more than 3 times, and dried ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

| Average width | aaaaa | aaaaa |

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com