3D printing preparation method of a light-transmitting cement-based composite material

A composite material and 3D printing technology, applied in processing and manufacturing, additive processing, etc., can solve the problems of complex preparation process, optical fiber spacing distribution and poor size consistency, and achieve the effect of simple process, low labor cost and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

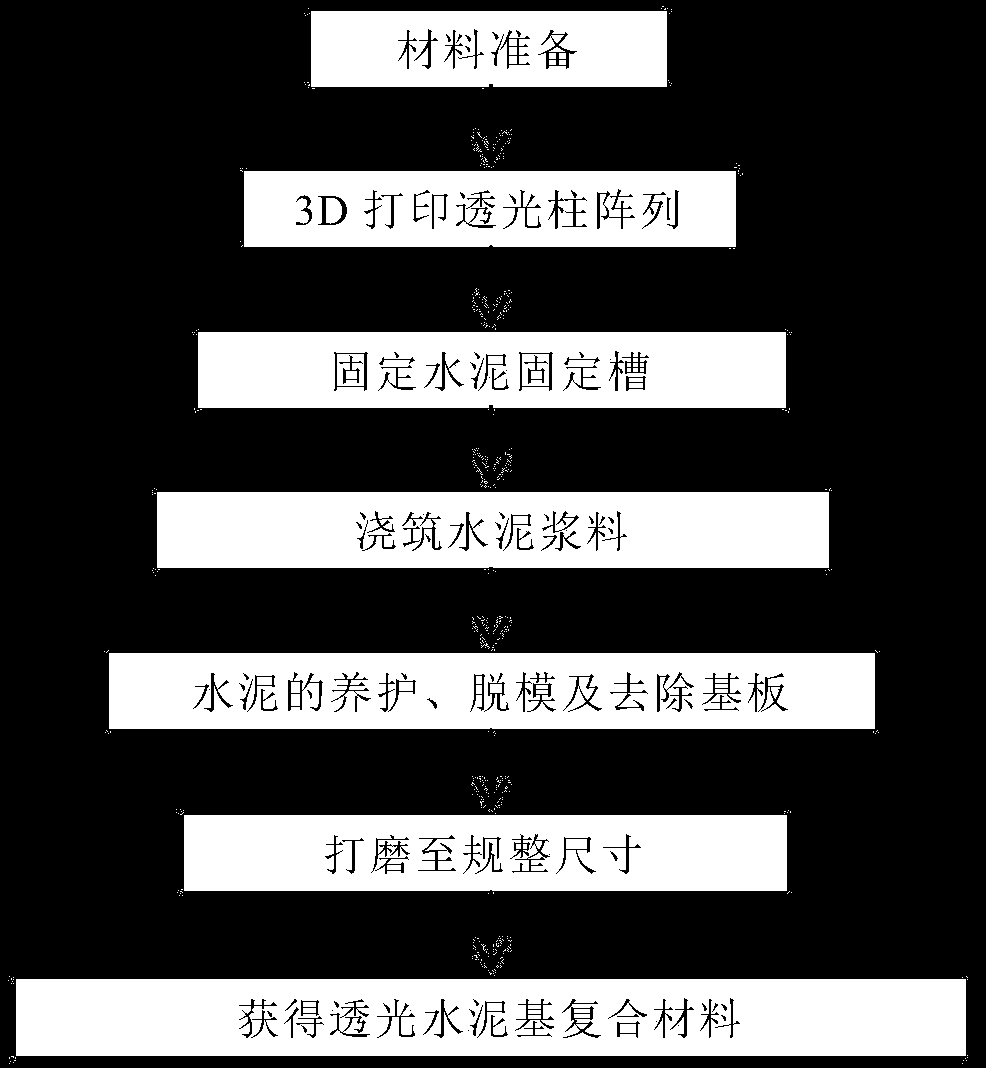

[0026] refer to figure 1 , the present invention prepares the steps of light-transmitting cement-based composite material as follows:

[0027] (1) Material preparation

[0028] Prepare epoxy resin, sulfoaluminate cement, admixtures, water, and steel plate substrate.

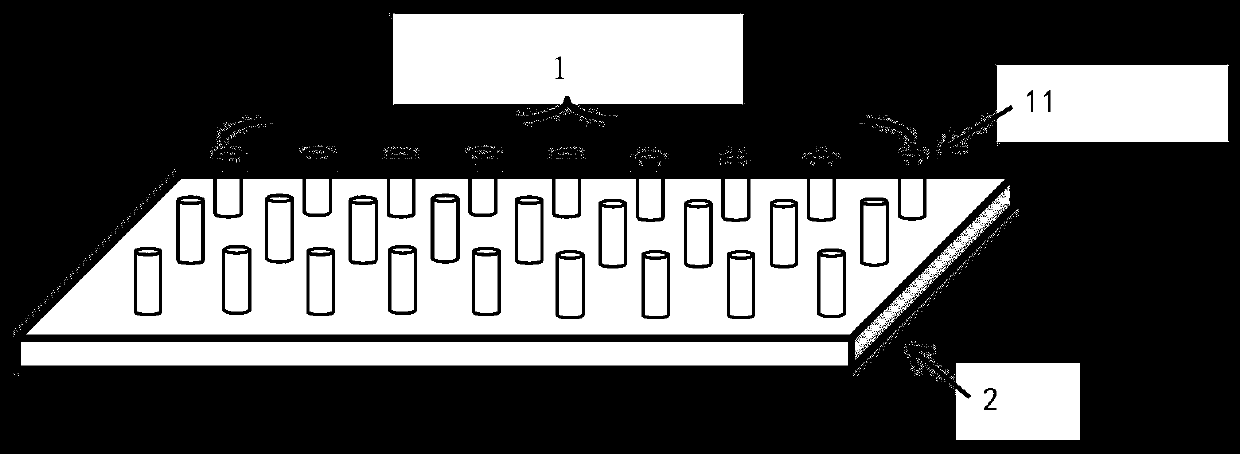

[0029] (2) Preparation of light-transmitting column array

[0030] Using epoxy resin as the raw material, the 3D printer prints the light-transmitting column array on the steel substrate according to the requirements. The cross-sectional shape of the light-transmitting column parallel to the substrate is circular.

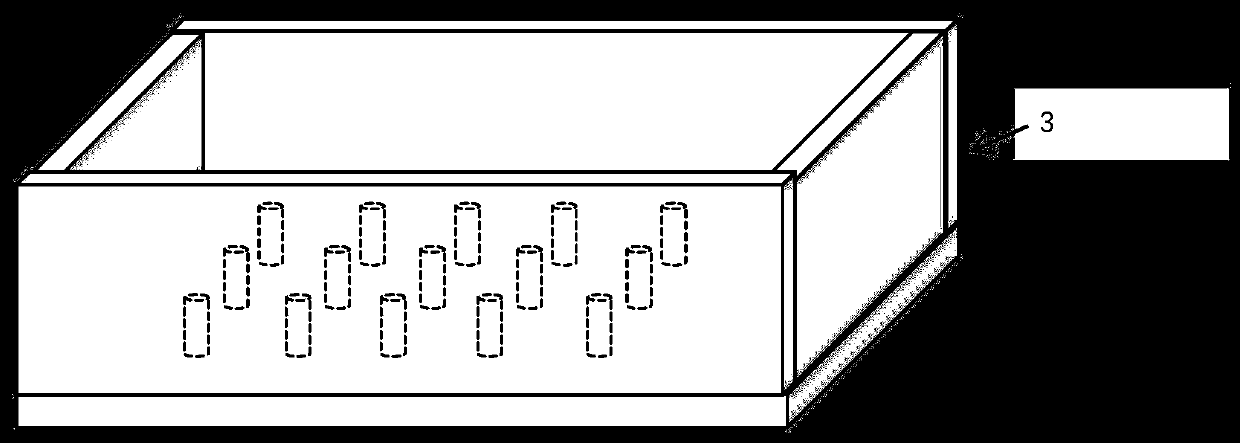

[0031] (3) Pouring cement slurry

[0032] After the light-transmitting column array is printed and cured, fix the cement fixing groove around the substrate, then prepare the cement slurry with sulfoaluminate cement, epoxy resin, admixture and water, and pour the prepared slurry into place A cement matrix is formed in the cement fixing groove with the base plate and the light-transmitting column...

Embodiment 2

[0036] The present invention prepares the steps of light-transmitting cement-based composite material as follows:

[0037] (1) Preparation of materials

[0038] Prepare epoxy resin, sulfoaluminate cement, fine aggregate, admixture, water reducer and water.

[0039] (2) Preparation of light-transmitting column array

[0040] Using epoxy resin as the raw material, the 3D printer can print the substrate and the light-transmitting column array as required. The height of the printed light-transmitting column is 50mm, the radius is 4mm, and the distance between adjacent light-transmitting columns is 8mm, parallel to the direction of the substrate. The cross-sectional shape of the light-transmitting column on the top is circular.

[0041] (3) Pouring cement slurry

[0042] After the printing is finished and solidified, fix the cement fixing groove around the substrate, then prepare the cement slurry with sulphoaluminate cement, fine aggregate, admixture and water, and pour the pre...

Embodiment 3

[0046] The present invention prepares the steps of light-transmitting cement-based composite material as follows:

[0047] (1) Preparation of materials

[0048] Prepare polycarbonate, Portland cement, admixtures, water, and plastic substrate.

[0049] (2) Preparation of light-transmitting column array

[0050] Using polycarbonate as the raw material, the 3D printer can print an array of light-transmitting columns on the plastic substrate according to the requirements. The cross-sectional shape of the light-transmitting column in the direction of the substrate is circular. (3) Pouring cement slurry

[0051] After the light-transmitting column array is printed and cured, fix the cement fixing groove around the substrate, then prepare cement slurry with Portland cement, admixture and water, pour the prepared slurry into the substrate and light-transmitting The cement of the column array is fixed in the groove, forming a cement matrix.

[0052] (4) demoulding and polishing

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com