Alloy steel and integrated brake beam frame and manufacturing method thereof

A technology for a braking beam frame and a manufacturing method, applied in the fields of railway freight cars and metallurgical materials, can solve the problems of unqualified mechanical properties, reduced production efficiency, waste of resources, etc., and achieves the effect of good comprehensive mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Embodiment 1 provides an alloy steel, and its specific chemical composition is shown in Table 4.

[0048] The alloy steel of this example is processed by using the scheme 3 recorded in the document "Li Jie, Tang Zhenying, Zheng Guanxing. Research on Forming Technology of Integrated Brake Beam [J], Forging and Stamping, 2014(13): 65-69." , to obtain an integrated brake beam frame.

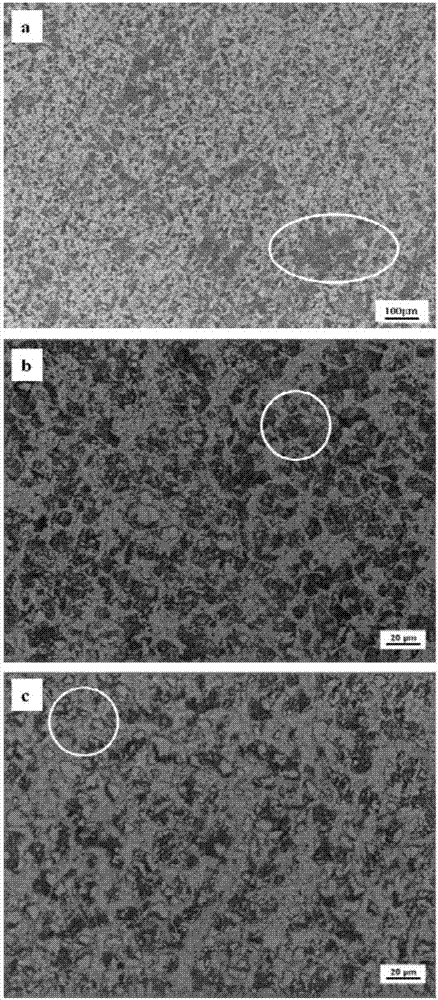

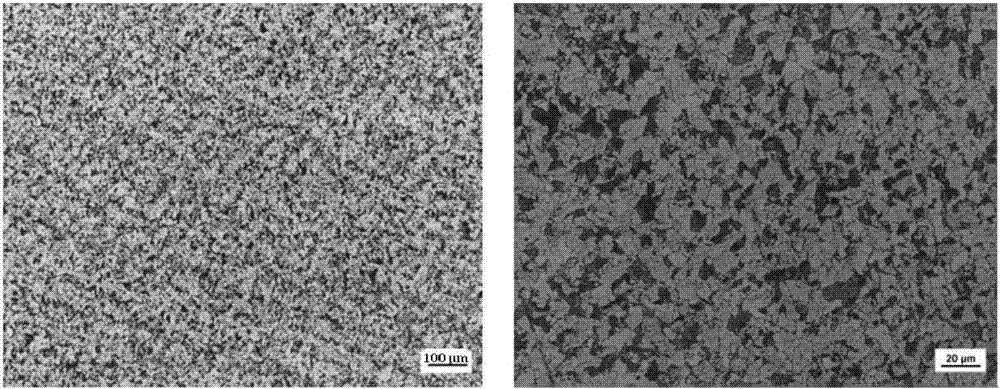

[0049] Take the sample of the integrated brake beam frame in this embodiment, perform mechanical polishing after rough grinding and fine grinding, and corrode with nitric acid alcohol solution (4%), under different magnifications, the metallographic photos of the sample are as follows: image 3 shown. It can be seen that the integrated brake beam sample of this embodiment has fine grains, and the microstructure is uniformly distributed ferrite and pearlite, that is, a uniform normalized tough structure, and the iron The sum of the volume content of ferrite and pearlite is more than 95%.

...

Embodiment 2-4

[0058] Examples 2-4 respectively provide an alloy steel, whose chemical composition is shown in Table 4.

[0059] The alloy steel provided in embodiment 2-4 is used as raw material to process and manufacture the integrated brake beam frame, and its specific process includes the following steps:

[0060] S1: The alloy steel is rolled according to a conventional process to obtain a section steel.

[0061] S2: Heating the section steel. The equipment used is the HKTP-450KW CNC induction heating machine tool production line (rated output power 450KW) produced by Hubei Shiyan Hengjin Technology Co., Ltd., and the heating frequency is controlled by adjusting the output power of the equipment. Specifically The process parameters of heat treatment are as shown in Table 6 below:

[0062] Table 6 Embodiment 2-4 Process parameters of heat treatment of medium steel

[0063]

[0064] Among them, in the third stage, the temperature of the shaped steel rises to about 740°C, in the sixth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com