Gas combustion heating furnace capable of reducing emission of nitrogen oxides and organic volatile matters

A technology of organic volatiles and nitrogen oxides, which is applied in lighting and heating equipment, indirect carbon dioxide emission reduction, burners, etc. Achieve the effects of full mixing and staged combustion, low investment costs, and reduced emissions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

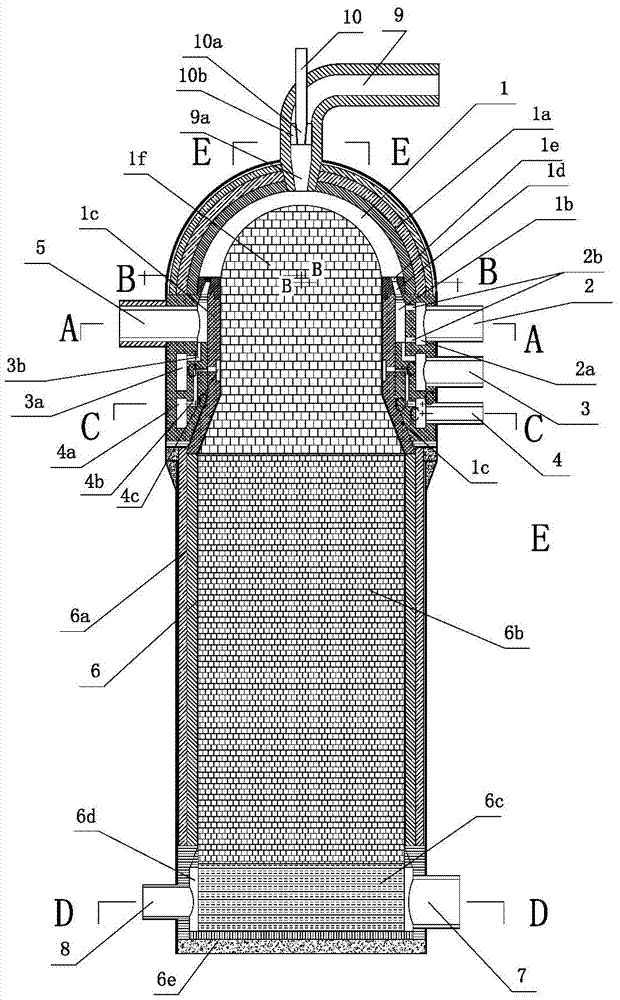

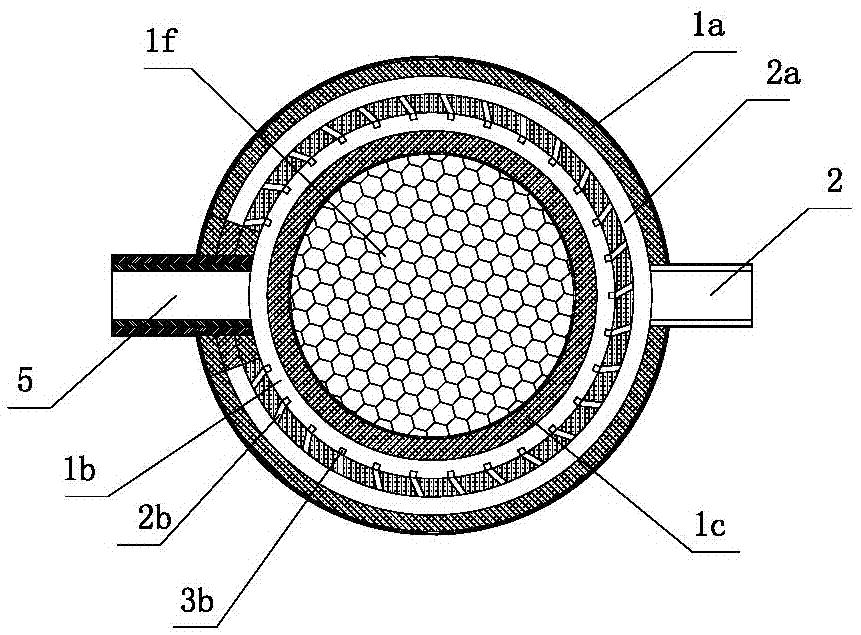

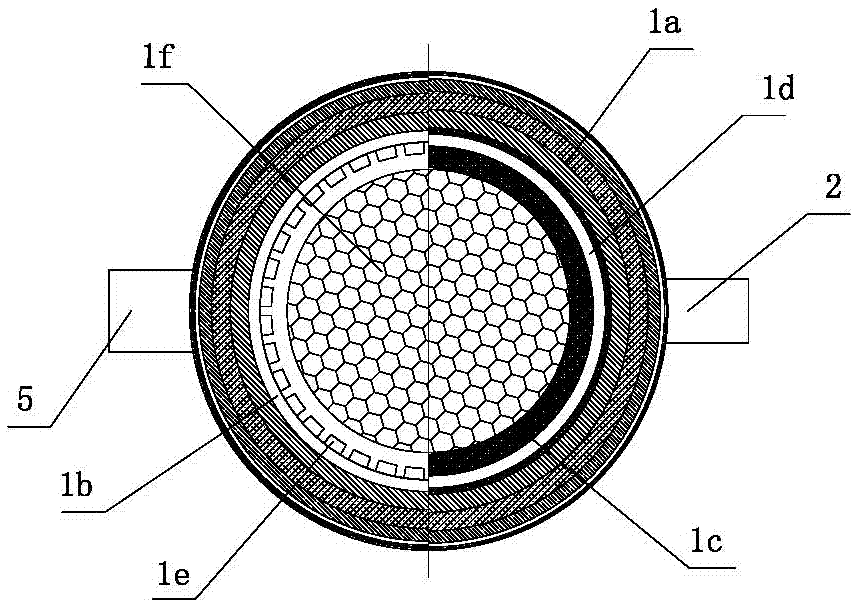

[0014] Depend on Figure 1-Figure 6Given, the structure of the present invention is that the premixed prechamber 1 is the inner space of the lower opening of the premixed prechamber wall 1a formed by butting the upper hemispherical vault and the lower cylindrical wall, The inner side of the cylindrical wall is provided with a shrinking ring wall 1c, and the inner wall of the shrinking ring wall has a secondary air guide ring groove 4c connected with the premixed pre-combustion chamber, and the upper part between the shrinking ring wall and the cylindrical wall is set There is a mixed diversion ring 1b, and the top of the mixed diversion ring has a progressively shrinking annular gap 1d upwards, and the top of the annular gap is evenly distributed around the top of the annular gap with mixed gas nozzles 1e communicating with the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com