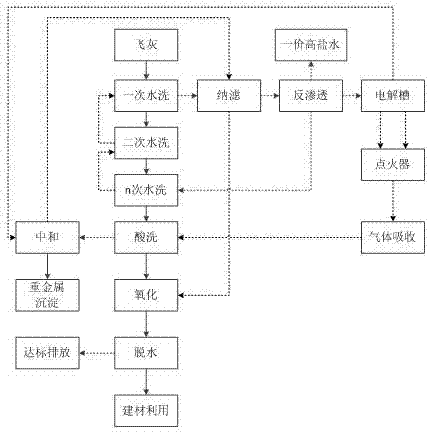

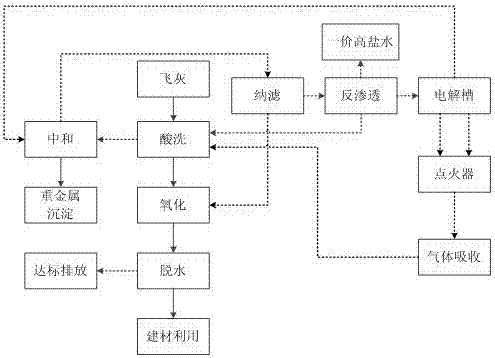

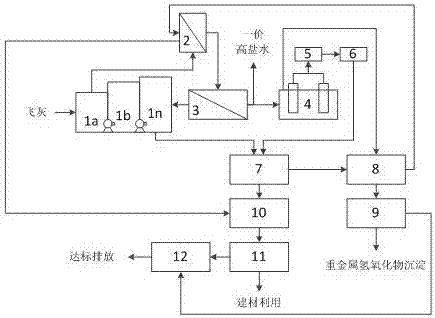

Low-energy incineration fly ash innocent treatment method and device

A technology of harmless treatment and incineration of fly ash, which is applied to chemical instruments and methods, transportation and packaging, and solid waste removal, etc., which can solve the problems of high treatment costs, incomplete treatment, and high energy consumption of dioxin heat treatment. Achieve the effects of avoiding damage, solving complex components, and saving pharmaceutical costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0091] 1kg of fly ash from a domestic waste incineration plant is processed by this device, and the Cl in the washing mixture - The concentration is 151, the pickling pH is 4, the pickling time is 2h, and the stirring speed is 800r / min; the pH of the neutralization reaction in the first step is 6.5, and 20% Na 2 SO 4 Solution 17ml, the pH of the neutralization reaction in the third step is 7.7, and the pH of the neutralization reaction in the fourth step is 9.5; add 10% sulfuric acid solution to the oxidation reaction until the pH is 3.2, add iron powder and react for 20 minutes, add 30% H 2 o 2 Solution, aeration reaction 2h, the test results are shown in the following table:

[0092]

Embodiment 2

[0094] 1kg of fly ash from a domestic waste incineration plant is processed by this device, and the Cl in the washing mixture - The concentration is 102, the pickling pH is 4.5, the pickling time is 2.5h, and the stirring speed is 600r / min; the pH of the neutralization reaction in the first step is 6.7, and 20% Na 2 SO 4 Solution 27ml, the pH of the neutralization reaction in the third step is 7.9, and the pH of the neutralization reaction in the fourth step is 9.7; add 10% sulfuric acid solution to the oxidation reaction until the pH is 3.7, add iron powder and react for 20 minutes, add 30% H 2 o 2 Solution, aeration reaction 2h, the test results are shown in the following table:

[0095]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com