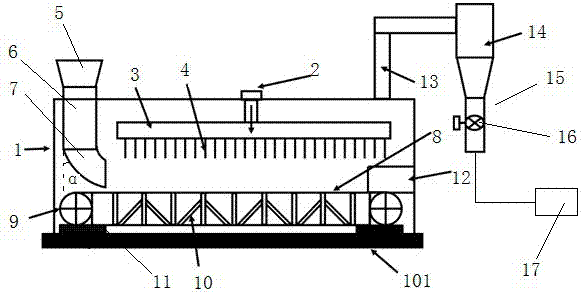

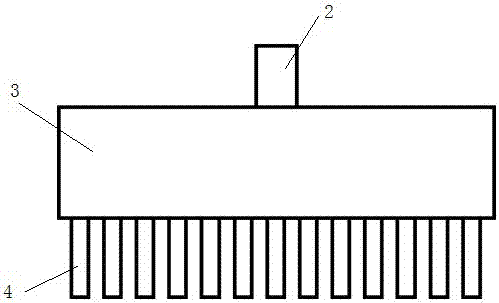

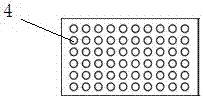

Device and method for thermally drying oil sludge through waste heat of high temperature furnace

A high-temperature furnace and sludge technology, which is used in the petroleum industry, the preparation of liquid hydrocarbon mixtures, dehydration/drying/concentrated sludge treatment, etc., can solve the problem of insufficient utilization of heat, and achieve good drying effect, Even heating effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0058] Example: The sludge sample with 20% oil and 40% water content is continuously fed into the drying chamber at a rate of 20 t / h, and the high temperature flue gas at 250°C is 8960.0 Nm 3 The rate of / h enters the high temperature flue gas chamber from the air inlet, selects a gear setting through the control device, and ejects from the purge needle. The conveyor belt transports sludge materials forward at a running speed of 2.78 mm / s (the residence time of sludge in the drying tank is 2h). In this process, the high-temperature flue gas exchanges heat with the sludge material and then the oil and gas and water vapor generated during the drying process of the sludge are passed along with the waste flue gas through the exhaust pipe into the condensing device for cooling, and the formed oil and water are cooled. The liquid enters the oil-water separation device for separation and is separately recovered. The non-condensable flue gas enters the flue gas treatment device to be pu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com