A kind of hard coating anti-fingerprint additive and preparation method thereof

A hard coating and additive technology, applied in coatings, biocide-containing paints, anti-fouling/underwater coatings, etc., can solve problems such as unsatisfactory coating compatibility and achieve excellent friction resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

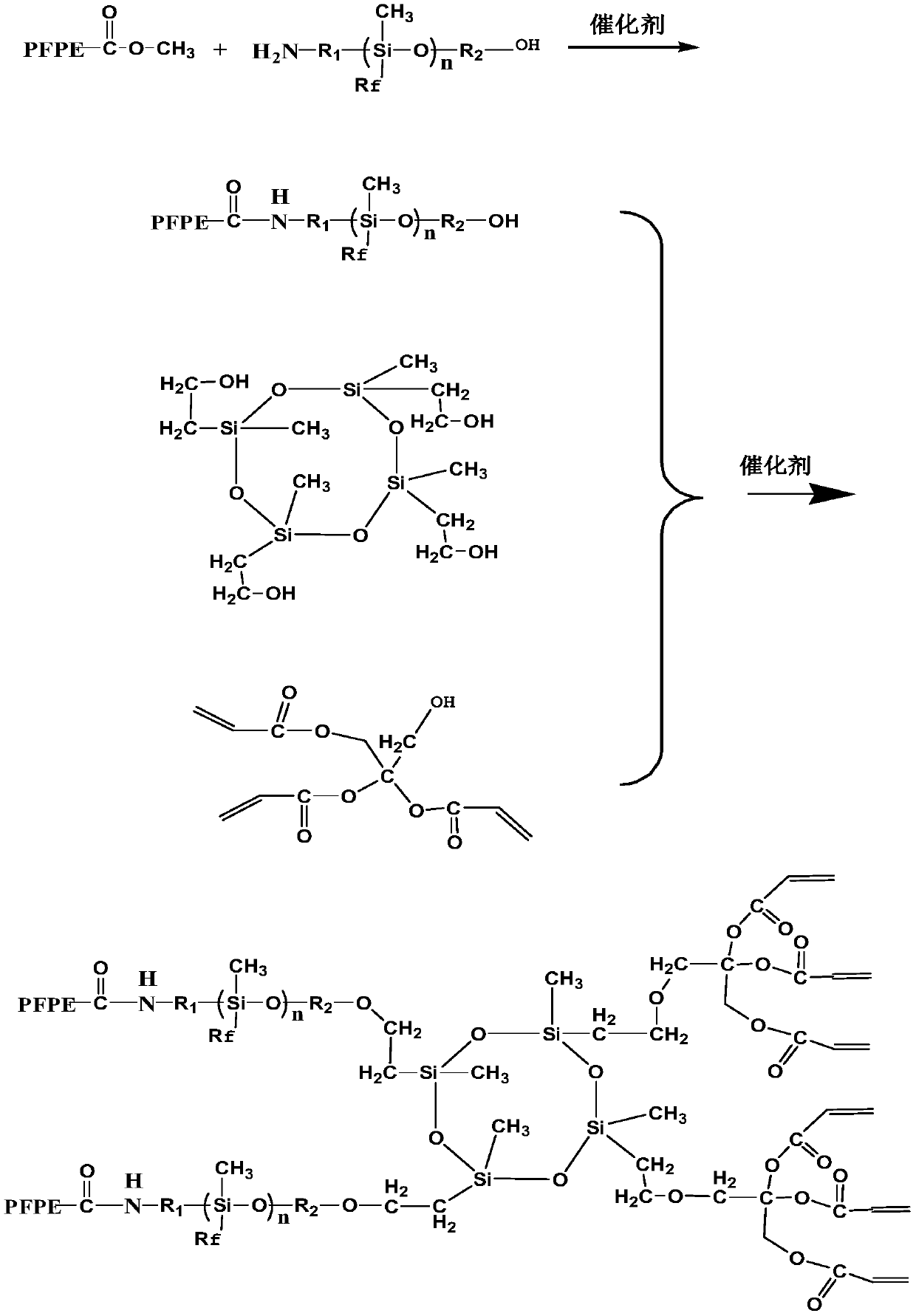

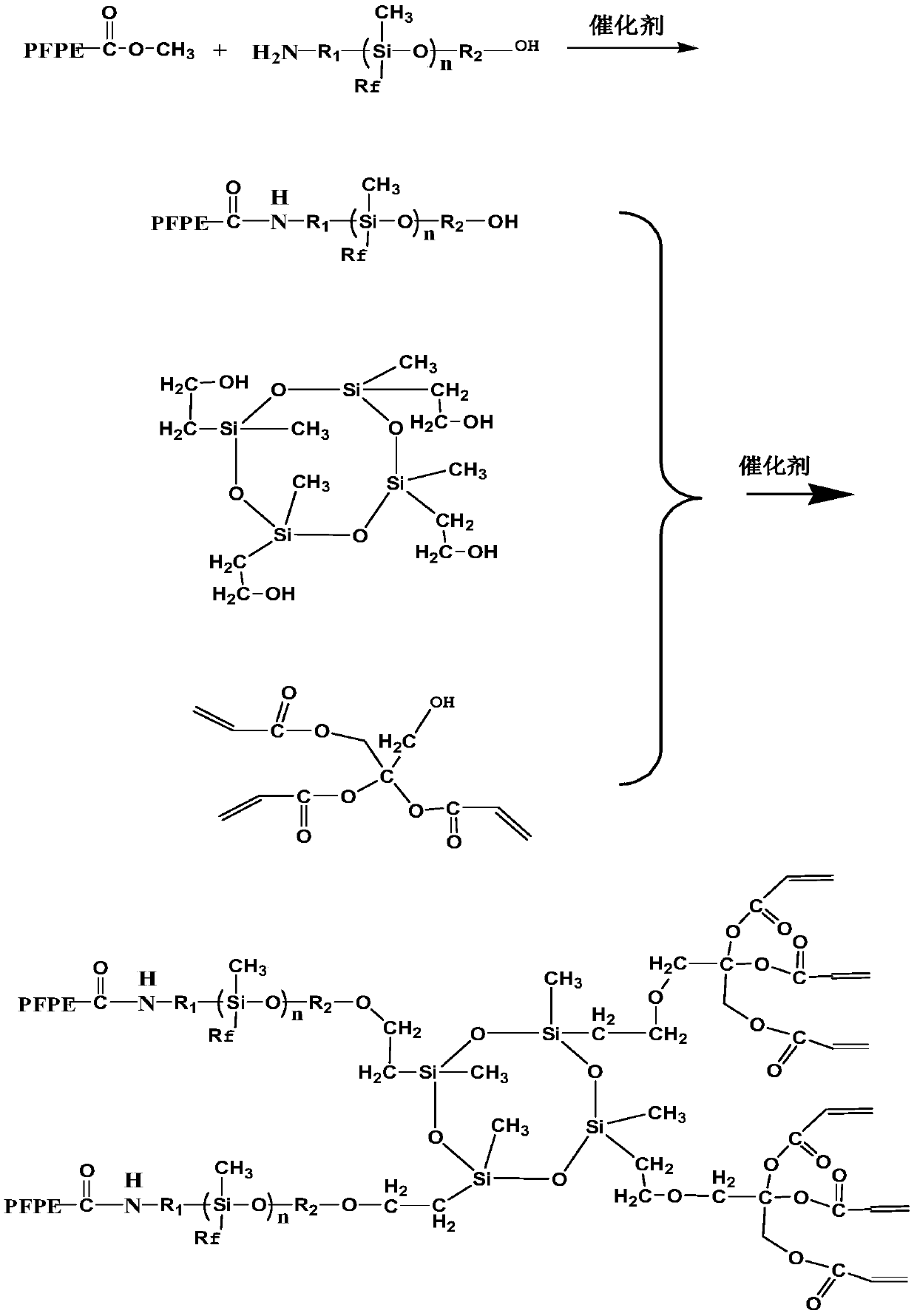

Method used

Image

Examples

Embodiment 1

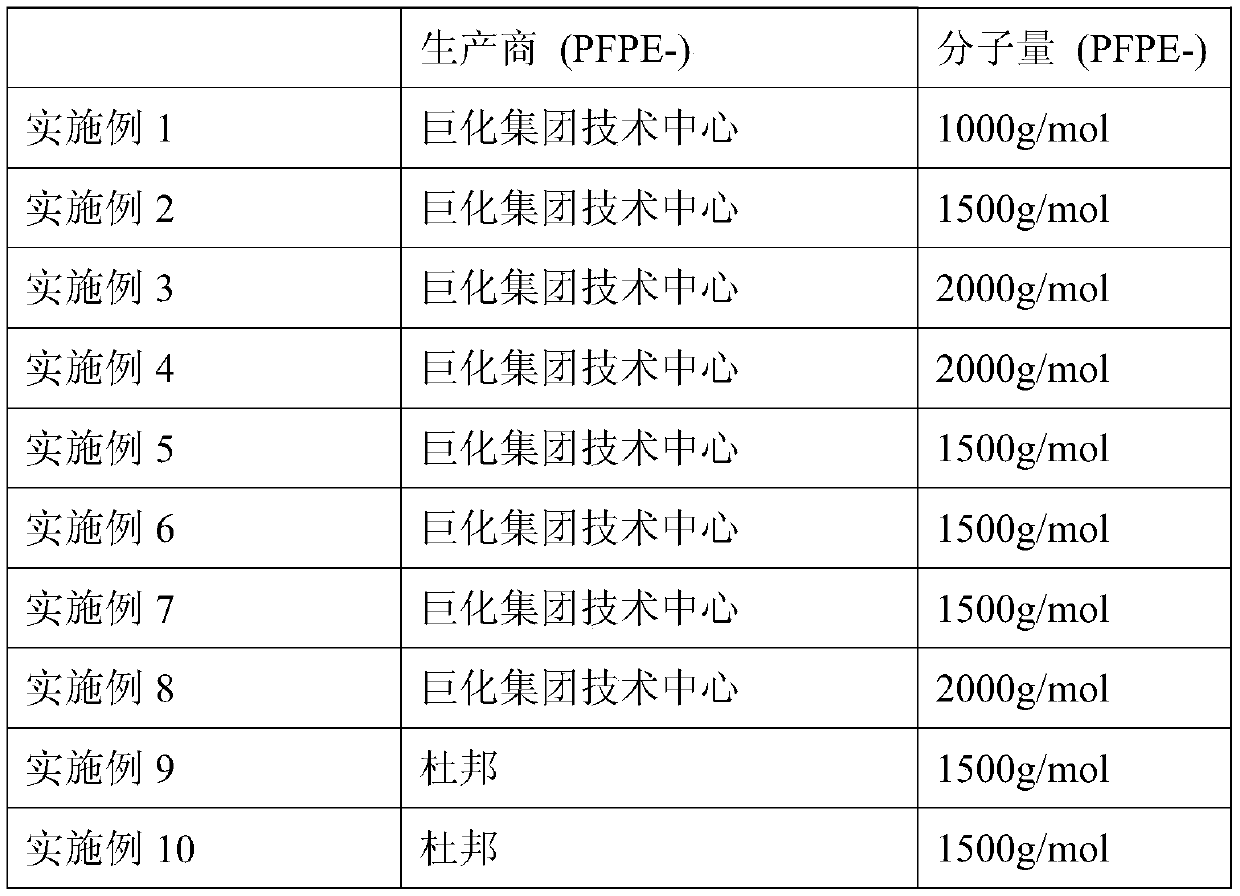

[0066] Table 3 Embodiment 1~12 reaction conditions

[0067] In a 250ml three-necked flask equipped with a constant pressure titration funnel, stirrer, heating mantle, and thermometer, feed nitrogen, add 0.01mol of perfluoropolyether ester, add solvent A with a volume of 1 / 3V, and stir at a speed of 300r / min Make it fully dissolved, add 0.01mol of aminohydroxy silicone oil to the constant pressure funnel, the volume of solvent A is 1 / 3V, 2h titration is over, and react at temperature T1 for t1 hour to obtain 20% perfluoropolyether and fluorine-containing polysiloxane block polymers.

[0068] Add 0.02mol of the block polymer and catalyst into the reaction flask, add 0.01mol of cyclic siloxane compound and 1 / 3V solvent A dropwise into the reaction solution, and react at temperature T2 for t2 hours; then continue to drop the monomer iv), react at the reaction temperature for t3h; cool to room temperature, and dilute the reaction liquid with solvent B to a solid content of 20%, wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| contact angle | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com