Low temperature resistant PVC film and preparation method thereof

A technology of PVC film and low temperature resistance, which is applied in the field of low temperature resistant PVC film and its preparation, and can solve the problems of low flame retardant efficiency, reduced flame retardancy, and poor low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of low-temperature resistant PVC film, its preparation raw material comprises the component of following parts by weight: 100 parts of PVC elastomer resin powders (containing the vinyl chloride-vinyl acetate copolymer of 4.5%), 30 parts of linear chains are C9 phthalo Ester, 10 parts DOA and 20 parts Reofos.

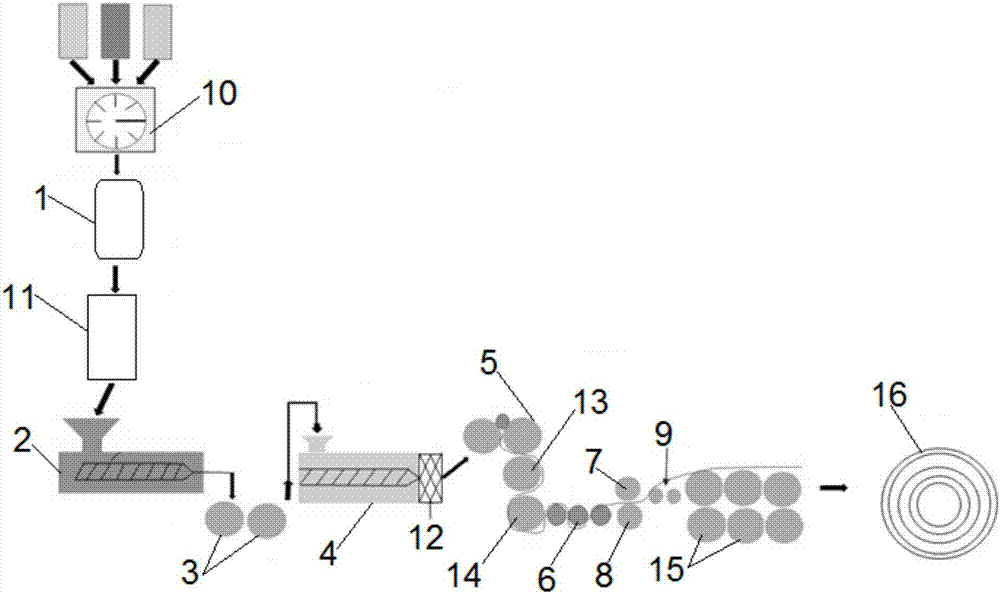

[0024] The preparation method of above-mentioned low temperature resistant PVC film is as figure 1 As shown, it includes the following steps: after weighing the components in proportion, add them to the high-speed mixer 1 and mix them evenly, then enter the internal mixer 2 (also can be a planetary extruder) for internal mixing and plasticization, and then enter the double-roller open The refining machine 3 is then plasticized to make it uniform, and then the rubber material enters the filter 4 to filter impurities, and then is rolled by the inverted L-shaped 4-wheel calender 5. The wheel set composed of Ra 0.07um rubber wheel 8 is embossed and formed, fol...

Embodiment 2

[0028] A kind of low-temperature-resistant PVC film, its preparation raw material comprises the following components by weight: 100 parts of PVC elastomer resin powder (containing 4% vinyl chloride-vinyl acetate copolymer), 34 parts of straight chains are C9 phthalo Ester, 11 parts of DOA, 18 parts of Reofos and 0.5 parts of fatty alcohol-C12-15-polyoxyethylene ether.

[0029] The preparation method of above-mentioned low temperature resistant PVC film is as figure 1 As shown, it includes the following steps: after weighing the components in proportion, add them to the high-speed mixer 1 and mix them evenly, then enter the internal mixer 2 (also can be a planetary extruder) for internal mixing and plasticization, and then enter the double-roller open The refining machine 3 is then plasticized to make it uniform, and then the rubber material enters the filter 4 to filter impurities, and then is rolled by the inverted L-shaped 4-wheel calender 5. The wheel set composed of Ra 0....

Embodiment 3

[0033] A kind of low-temperature-resistant PVC film, its preparation raw material comprises the following components by weight: 100 parts of PVC elastomer resin powder (containing 5% vinyl chloride-vinyl acetate copolymer), 38 parts of straight chains are C10 phthalo Ester, 12 parts DNA, 16 parts Disflamoll, 2 parts fatty alcohol-C12-15-polyoxyethylene ether and 4 parts calcium zinc stabilizer.

[0034] The preparation method of above-mentioned low temperature resistant PVC film is as figure 1As shown, it includes the following steps: after weighing the components in proportion, add them to the high-speed mixer 1 and mix them evenly, then enter the internal mixer 2 (also can be a planetary extruder) for internal mixing and plasticization, and then enter the double-roller open The refining machine 3 is then plasticized to make it uniform, and then the rubber material enters the filter 4 to filter impurities, and then is rolled by the inverted L-shaped 4-wheel calender 5. The w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com