Preparation method of organic-inorganic composite attapulgite mycotoxin adsorbent

A mycotoxin adsorption, attapulgite technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of lack of specific adsorption, loss of nutrient components, unfavorable environmental protection, etc., and is conducive to large-scale production. , the effect of improving adsorption capacity and good environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

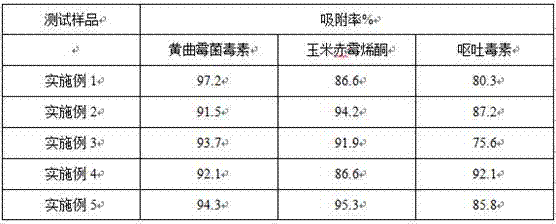

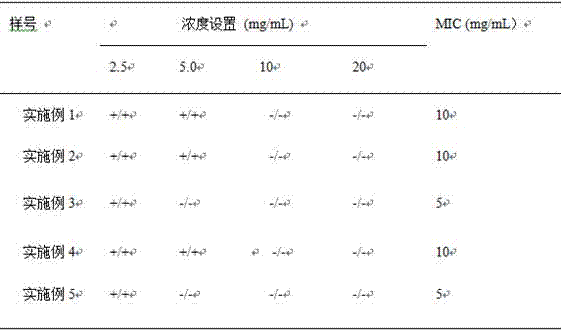

Examples

Embodiment 1

[0025] Example 1: Take 100g of acid-activated attapulgite, mix it into a slurry with a mass concentration of 10%, add 5% N-hydroxypropyltrimethylammonium chloride chitooligosaccharide of the attapulgite quality, and stir at 75°C After 2 hours, add acid-modified activated carbon with 5% of the mass of attapulgite and continue to react at this temperature for 2 hours, cool down, centrifuge, wash, dry, and pulverize to obtain an organic-inorganic composite attapulgite mycotoxin adsorbent.

Embodiment 2

[0026] Embodiment 2: Take 100g of acid-activated attapulgite, mix it into a slurry with a mass concentration of 10%, add 10% N-hydroxypropyltrimethylammonium chloride chitooligosaccharide of the attapulgite quality, and stir at 80°C After 2 hours, add acid-modified activated carbon with 10% of the mass of attapulgite and continue to react at this temperature for 2 hours, cool down, centrifuge, wash, dry, and pulverize to obtain an organic-inorganic composite attapulgite mycotoxin adsorbent.

Embodiment 3

[0027] Embodiment 3: Take 100g of acid-activated attapulgite, mix it into a slurry with a mass concentration of 5%, add 20% O-hydroxypropyltrimethylammonium chloride chitooligosaccharide of the attapulgite quality, and stir at 80°C After 2 hours, add acid-modified activated carbon with 2% of the mass of attapulgite and continue to react at this temperature for 2 hours, cool down, centrifuge, wash, dry, and pulverize to obtain an organic-inorganic composite attapulgite mycotoxin adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com