Separation type Venturi tube hybrid electrocatalysis ozonizing method and device

A technology of tubular mixing and Venturi tube, applied in chemical instruments and methods, oxidized water/sewage treatment, special compound water treatment, etc., can solve the problems of pollution, inability to effectively treat various specific pollutants in water, etc., and achieve elimination Effects of pollution, life extension, and ecological safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

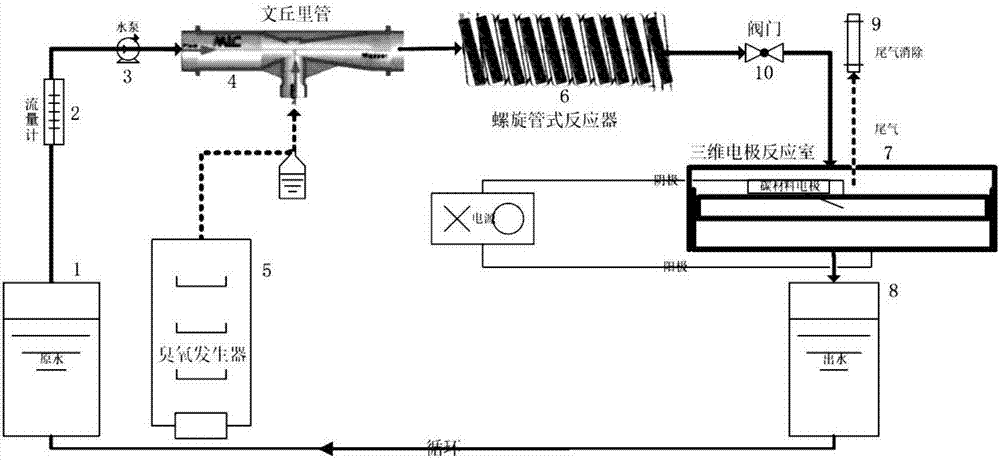

[0040] Prepare 500ml of sewage containing bisphenol A (BPA) 10mg / l, self-made nitrogen-doped carbon nanotube membrane electrode as cathode, counter electrode as titanium sheet, DC voltage 3V, reaction initial pH 10.2, initial current 15mA, ozone generation concentration 8 %, flow 0.5L / min. use figure 1 reaction device. Determination of the removal rate of effluent TOC:

[0041] time (min)

Embodiment 2

[0043] Prepare 500ml of sewage containing bisphenol A (BPA) 10mg / l, self-made nitrogen-doped carbon nanotube membrane electrode as anode, counter electrode as titanium sheet, DC voltage 3V, reaction initial pH 10.2, initial current 15mA, ozone generation concentration 8 %, flow 0.5L / min. use figure 1 reaction device. Determination of the removal rate of effluent TOC:

[0044] time (min)

Embodiment 3

[0046] Prepare 500ml of sewage containing bisphenol A (BPA) 10mg / l, self-made multi-walled carbon nanotube membrane electrode as cathode, counter electrode as titanium sheet, DC voltage 3V, reaction initial pH 10.2, initial current 15mA, ozone generation concentration 8 %, flow 0.5L / min. use figure 1 reaction device. Determination of the removal rate of effluent TOC:

[0047] time (min)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com