Bean product waste water treatment device

A technology for soy product wastewater and treatment device, which is applied in the food industry wastewater treatment, multi-stage water treatment, flotation water/sewage treatment and other directions, can solve the problems of easy acidification, corrosion, concentrated drainage time, etc. Other harmful substances, the fermentation reaction is sufficient, and the effect of reducing the transportation link

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

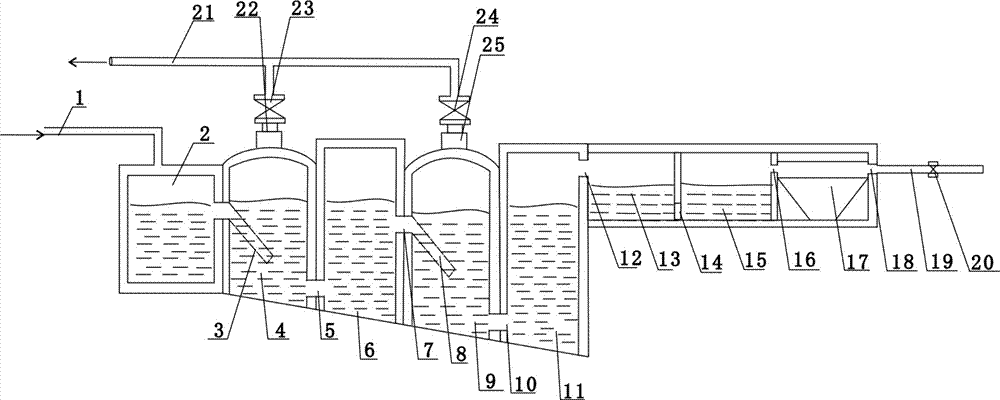

[0015] Such as figure 1 As shown, a bean product wastewater treatment device includes a wastewater buffer pool 2, a first biogas tank 4, a first water pressure room 6, a second biogas tank 9, a second water pressure room 11, a sedimentation tank 13, and wastewater aeration Pool 15, thickening filter pool 17.

[0016] The waste water buffer pool 2 is connected to the water inlet pipe 1, the waste water buffer pool 2 is connected to the first biogas digester 4 through the first inclined water inlet pipe 3, and the first biogas digester 4 communicates with the first water pressure room 6 through the first diversion hole 5 , the first water pressure room 6 is connected to the second biogas tank 9 through the second inclined water inlet pipe 8 , and the second biogas tank 9 communicates with the second water pressure room 11 through the third guide hole 10 .

[0017] The second water pressure room 11 is communicated with the sedimentation tank 13 through the fourth diversion hole ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com