Compound, warm mix asphalt, asphalt mixture, preparation method of compound and application

A warm-mix asphalt and compound technology, which is applied in the field of road asphalt, can solve the problems of high cost and high equipment requirements, and achieve the effect of low cost, simple preparation process and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

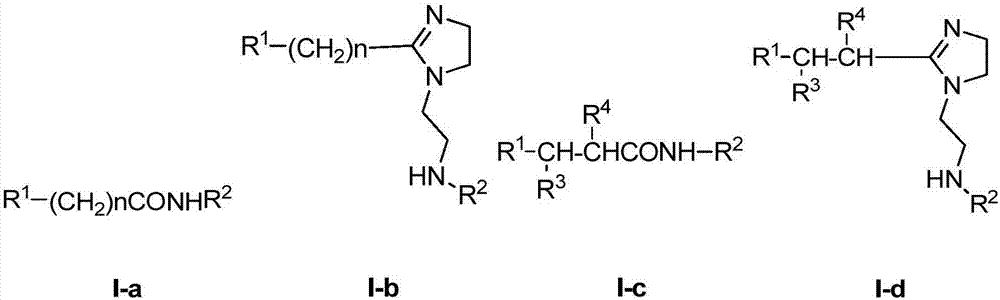

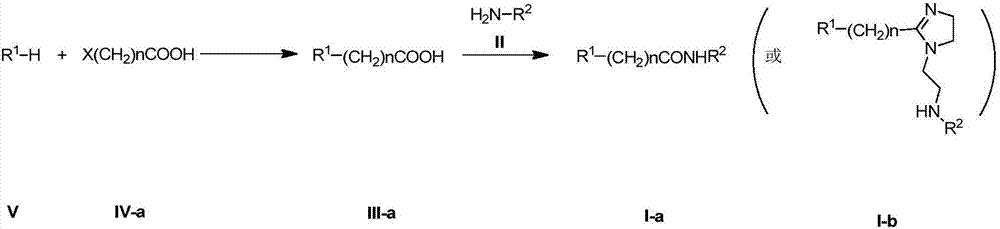

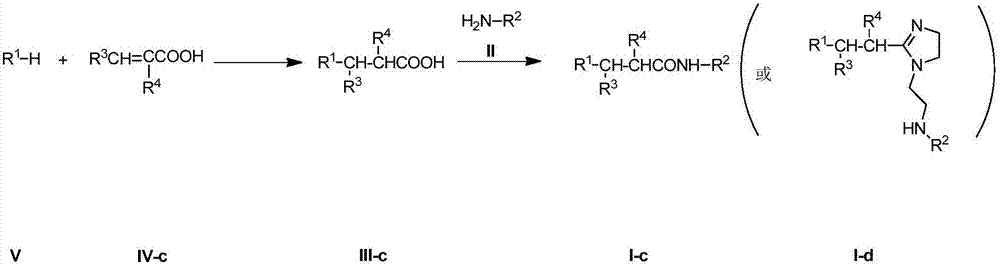

Method used

Image

Examples

Embodiment 1

[0055] Weigh the compound V-1 obtained by weighing oleic acid and triethylenetetramine prepared by a conventional method (prepared by a conventional method, mix oleic acid and triethylenetetramine in a molar ratio of 1:1, heat to 250-260 ° C, and blow nitrogen Dehydration can be prepared) a total of 392g was added to a 1000mL three-necked flask, and then slowly added chloroacetic acid IV-a-1 (94g, 1mol), the reaction temperature rose, the reaction temperature was controlled at 80 ° C, and the reaction was carried out for 3h to obtain compound III-a -1. Then triethylenetetramine II-1 (146g, 1mol) was added, the reaction temperature was raised to 180-190°C, water vapor was blown out with nitrogen gas, 18g of water was collected by the water separator, the reaction was stopped, and the temperature was lowered to obtain compound I-a-1. Yield was 614 g, 100% yield. 1 H NMR (400MHz, CDCl 3 )δppm 5.33(dt,J=6.8,12Hz,2H),3.62-3.60(m,1H),3.40-3.24(m,4H),3.20-3.15(m,1H),2.81-2.56(m,17H...

Embodiment 2

[0061] Weigh the compound V-2 prepared by conventional method with oleic acid and tetraethylenepentamine (prepared by conventional method, mix oleic acid and tetraethylenepentamine in a molar ratio of 1:1, heat to 250-260°C, blow nitrogen Dehydration can be obtained) a total of 435g was added to a 1000mL three-necked flask, and then acrylic acid IV-a-2 (72g, 1mol) was slowly added, the reaction temperature was raised, the reaction temperature was controlled at 80°C, and the reaction was carried out for 3h to obtain compound III-a- 2. Then tetraethylenepentamine II-2 (189g, 1mol) was added, the reaction temperature was raised to 180-190°C, water vapor was blown out with nitrogen gas, 18g of water was collected by the water separator, the reaction was stopped, and the temperature was lowered to obtain compound I-c-2. Yield was 678 g, 100% yield. 1 H NMR (400MHz, CDCl 3 )δppm 5.32(dt,J=6.8,11.6Hz,2H),3.67-3.60(m,1H),3.40-3.24(m,4H),3.21-3.13(m,1H),2.81-2.61(m,24H ), 2.58-2.41 ...

Embodiment 3

[0067]507g of compound III-a-2 was then added tetraethylenepentamine II-2 (189g, 1mol), the reaction temperature was raised to 260-270°C, and the water vapor was blown out with nitrogen gas. The water separator collected 36g of water, and the reaction was stopped. The compound I-b-2 was obtained by cooling down. Yield was 660 g, 100% yield. 1 H NMR (400MHz, CDCl 3 )δppm 5.32(dt,J=6.8,11.6Hz,2H),3.67-3.60(m,2H),3.40-3.24(m,4H),3.21-3.13(m,2H),2.81-2.61(m,22H ), 2.58-2.41 (m, 8H), 2.17-2.13 (m, 2H), 2.05-1.96 (m, 2H), 1.33-1.24 (m, 22H), 0.86 (t, J=6.8Hz, 3H).

[0068]

[0069] Preparation of warm-mix asphalt: Add warm-mix asphalt additive I-b-2 with an asphalt weight of 5‰ to molten 70# petroleum asphalt, heat to 135°C and stir for 20 minutes to obtain warm-mix asphalt.

[0070] Heat the obtained warm-mix asphalt to 135°C, and heat the aggregate to 135°C; then add 4% warm-mix asphalt and 96% AC-13 graded aggregate to the mixing pot, The warm mix asphalt mixture is prepar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com