A kind of phase-change heat-conducting material and its preparation method and composition for preparing phase-change heat-conducting material

A phase change thermal conductivity and composition technology, applied in the field of thermal conductive materials, can solve the problems of insufficient contact of components, reduced thermal conduction efficiency, large contact thermal resistance, etc., and achieve the effects of easy acquisition, improved thermal conduction efficiency, and reduced contact thermal resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

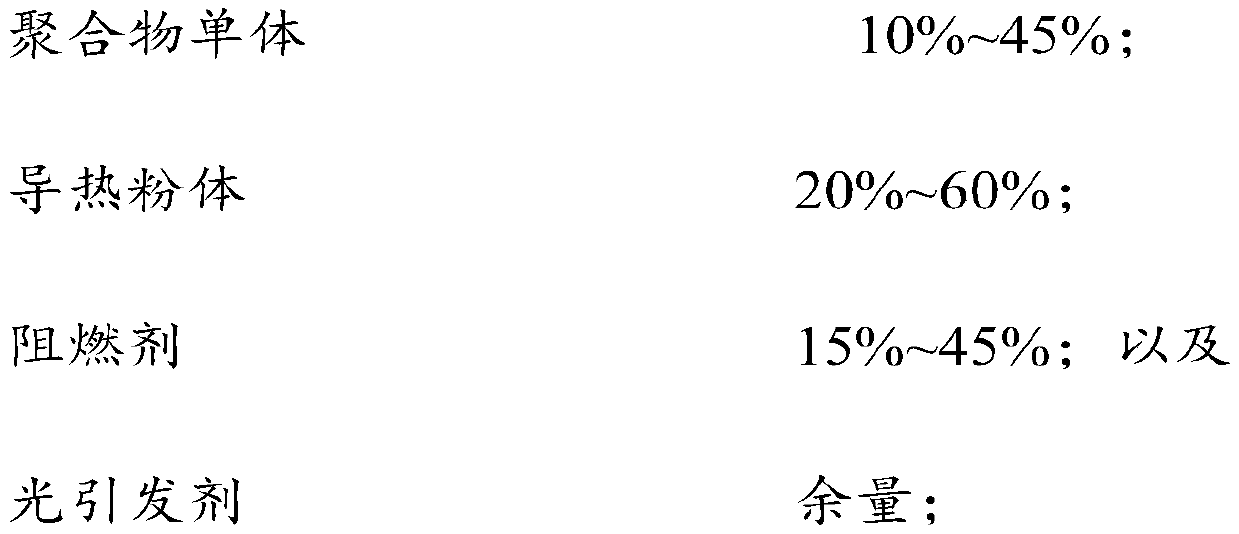

[0031] The embodiment of the present invention also provides a method for preparing the above-mentioned phase-change thermally conductive material, which includes: calendering a mixture of polymer monomers, thermally conductive powders, flame retardants and photoinitiators, and then photocuring and molding.

[0032] It should be noted that after photo-curing and molding, the polymer monomer undergoes a cross-linking reaction under the induction of the photo-initiator to form a spatial network structure, which tightly connects the heat-conducting powder and the flame retardant together.

[0033] After photocuring and molding, the network polymer is cured and formed, so that the phase change thermal conductive material forms a stable and excellent toughness space network skeleton, and each component is closely connected and embedded in the space network skeleton. This makes the toughness of the phase change thermally conductive material and the ability to adhere to components ver...

Embodiment 1

[0047] This embodiment provides a composition for preparing a phase-change thermally conductive material, which includes:

[0048] 10g of n-octyl acrylate, 30g of acrylonitrile, 60g of isopropyl methacrylate;

[0049] 225g of alumina powder;

[0050] 60g of aluminum hydroxide, 50g of fumed silica;

[0051] 2 g of 2-hydroxy-methylphenylpropan-1-one, 1 g of acylphosphine oxide.

Embodiment 2

[0053] This embodiment provides a composition for preparing a phase-change thermally conductive material, which includes:

[0054] 10g of 2-ethylhexyl acrylate, 40g of acrylonitrile, 50g of isopropyl methacrylate;

[0055] 150g of alumina powder, 50g of aluminum nitride powder;

[0056] 50g of aluminum hydroxide, 50g of fumed silica;

[0057] 1 g of acylphosphine oxide, 2 g of 2-methyl-1-(4-methylthiophenyl)-2-morpholino-1-propanone.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com