A kind of rewritable, optical anti-reflection coating and preparation method thereof

A coating and optical technology, which is applied in the field of functional polymer material synthesis, can solve the problems of declining wall aesthetics and affecting city appearance, etc., and achieve the effect of good rewritable function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

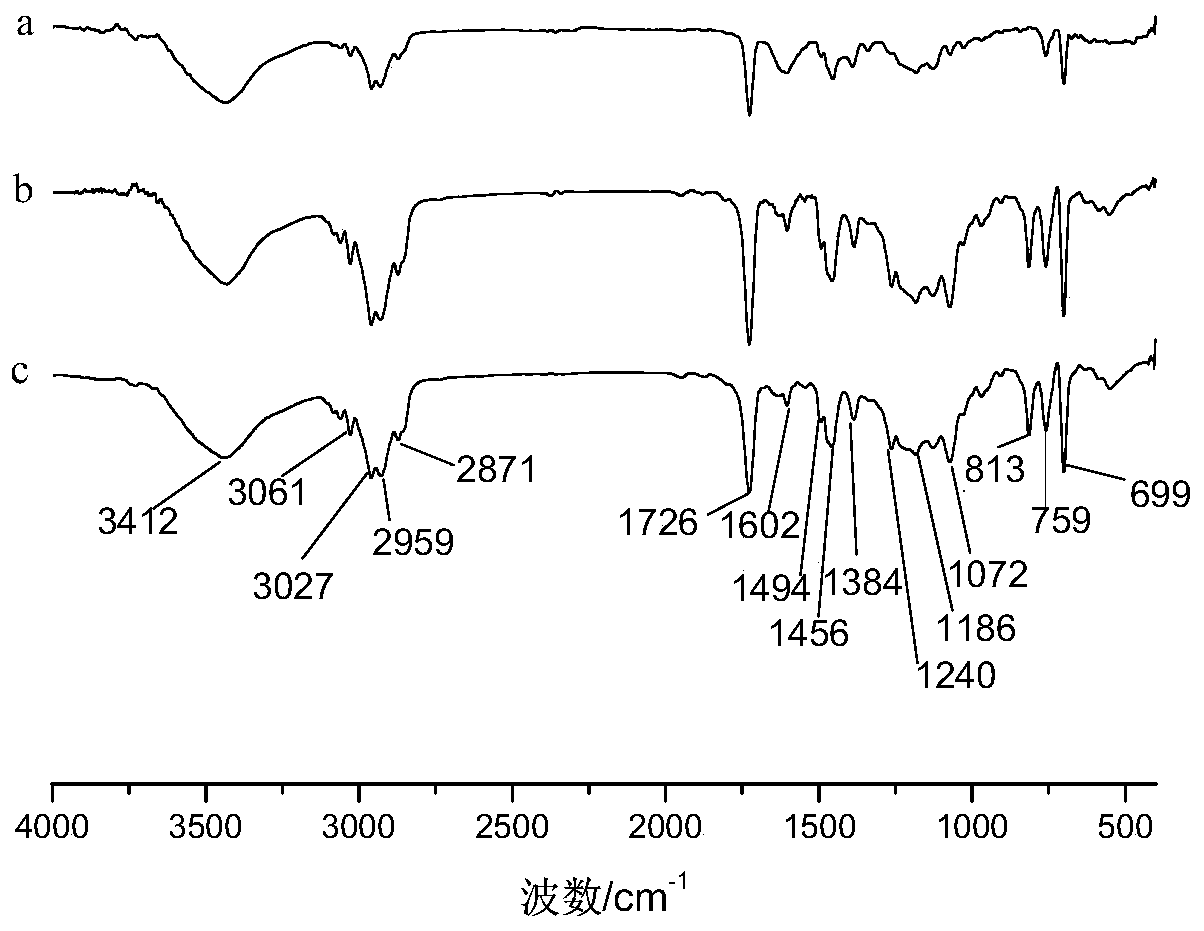

Image

Examples

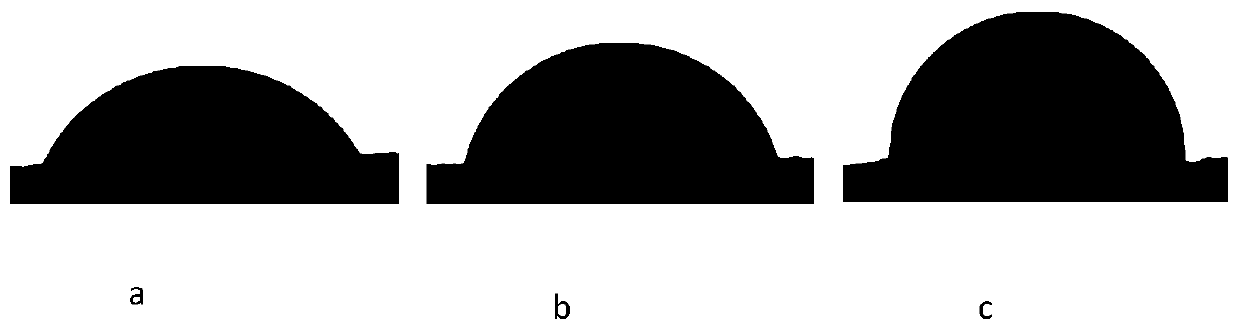

Embodiment 1

[0026] Preparation of fluorine-containing silicone styrene-acrylic emulsion: put 0.07g emulsifier, 0.07g divinylbenzene, 1.40g St and 60.00g deionized water in a 250ml flask equipped with a stirrer, thermometer and reflux condenser, and put Pre-emulsify in a 75°C water bath for 30min; then add 0.07g of 10% potassium persulfate aqueous solution, and 2 CO 3 The pH of the solution was adjusted to be stable at 9 to 10, and the reaction was carried out for 30 minutes; after completion, 12.60 g of St and 16.00 g of butyl methacrylate were slowly added dropwise with a constant pressure dropping funnel, and 2.56 g of 10% potassium persulfate aqueous solution and 3.00g of γ-methacryloxypropyltriethoxysilane and 5.00g of dodecafluoroheptyl methacrylate, during which the pH of the system was kept stable at 9-10; after the addition was completed, the temperature was raised to 80°C, After reacting for 4 hours, cool naturally to room temperature after completion, and end the reaction; obta...

Embodiment 2

[0031] Preparation of fluorine-containing silicone styrene-acrylic emulsion: put 0.07g emulsifier, 0.07g divinylbenzene, 1.40g St and 60.00g deionized water in a 250ml flask equipped with a stirrer, thermometer and reflux condenser, and put Pre-emulsify in a 75°C water bath for 30min; then add 0.07g of 10% potassium persulfate aqueous solution, and 2 CO 3 The pH of the solution was adjusted to be stable at 9 to 10, and the reaction was carried out for 30 minutes; after completion, 12.60 g of St and 16.00 g of butyl methacrylate were slowly added dropwise with a constant pressure dropping funnel, and 2.56 g of 10% potassium persulfate aqueous solution and 3.00g of γ-methacryloxypropyltriethoxysilane and 5.00g of dodecafluoroheptyl methacrylate, during which the pH of the system was kept stable at 9-10; after the addition was completed, the temperature was raised to 80°C, After 4 hours of reaction, it was naturally cooled to room temperature to end the reaction. A fluorine-con...

Embodiment 3

[0035] Preparation of fluorine-containing silicone styrene-acrylic emulsion: put 0.07g emulsifier, 0.07g divinylbenzene, 1.40g St and 60.00g deionized water in a 250ml flask equipped with a stirrer, thermometer and reflux condenser, and put Pre-emulsify in a 75°C water bath for 30min; then add 0.07g of 10% potassium persulfate aqueous solution, and 2 CO 3 The pH of the solution was adjusted to be stable at 9 to 10, and the reaction was carried out for 30 minutes; after completion, 12.60 g of St and 16.00 g of butyl methacrylate were slowly added dropwise with a constant pressure dropping funnel, and 2.56 g of 10% potassium persulfate aqueous solution and 3.00g of γ-methacryloxypropyltriethoxysilane and 5.00g of dodecafluoroheptyl methacrylate, during which the pH of the system was kept stable at 9-10; after the addition was completed, the temperature was raised to 80°C, After 4 hours of reaction, it was naturally cooled to room temperature to end the reaction. A fluorine-con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com