Low temperature dyeing process for polyester fibers

A low-temperature dyeing and polyester fiber technology, applied in dyeing, textiles and papermaking, etc., can solve the problems of large-scale industrial production, heavy pollution, and high cost, and achieve the goal of reducing energy consumption, reducing dyeing costs, and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

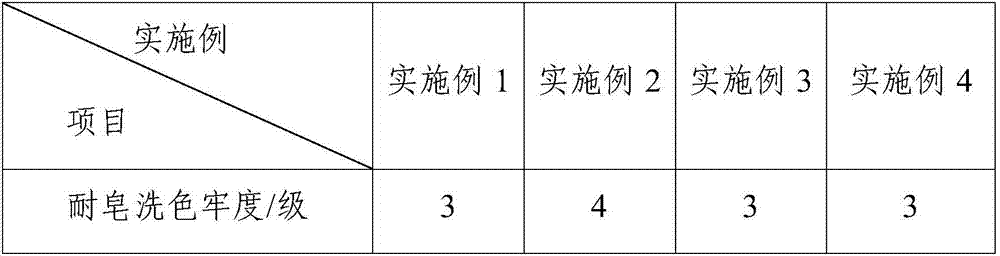

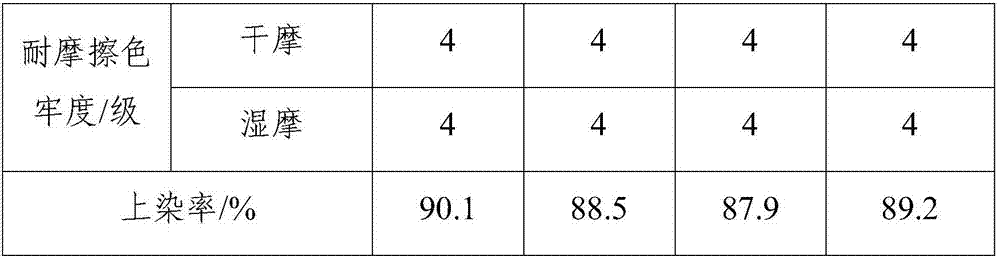

Examples

Embodiment 1

[0016] A low-temperature dyeing process for polyester fibers, comprising the following steps:

[0017] 1. Dissolve benzyl alcohol, dimethyl phthalate, sorbitan monooleate polyoxyethylene ether, Yatelong red AQE, and dispersant in a buffer solution with a pH value of 4.5-6.5 in sequence to prepare Dye liquor, and the temperature of dye liquor is raised to 50 ℃; the concentration of benzyl alcohol in the dye liquor is 4g / L, the concentration of dimethyl phthalate is 4g / L, sorbitan monooleate polyoxyethylene ether The concentration of the dispersant is 4g / L, and the concentration of the dispersant is 1.5g / L; the dosage of Yatelong Red AQE is 3% owf;

[0018] The buffer solution is prepared with potassium dihydrogen phosphate and an appropriate amount of acetic acid; the dispersant is a mixture of sodium methylene dimethyl naphthalene sulfonate and alkaline sodium lignosulfonate at a mass ratio of 1:2;

[0019] 2. Put the polyester fabric into the dyeing solution with a liquor ra...

Embodiment 2

[0021] A low-temperature dyeing process for polyester fibers, comprising the following steps:

[0022] 1. Dissolve benzyl alcohol, dimethyl phthalate, sorbitan monooleate polyoxyethylene ether, Yatrom blue AQE, and dispersant in a buffer solution with a pH value of 4.5-6.5 in sequence to prepare Dye liquor, and the temperature of dye liquor is raised to 55 ℃; the concentration of benzyl alcohol in the dye liquor is 3g / L, the concentration of dimethyl phthalate is 5g / L, sorbitan monooleate polyoxyethylene ether The concentration of the dispersant is 3g / L, the concentration of the dispersant is 1.5g / L; the dosage of Yatrolong Blue AQE is 5% owf;

[0023] The buffer solution is prepared with potassium dihydrogen phosphate and an appropriate amount of acetic acid; the dispersant is a mixture of sodium methylene dimethyl naphthalene sulfonate and alkaline sodium lignosulfonate at a mass ratio of 1:1;

[0024] 2. Put the polyester fabric into the dyeing solution with a liquor ratio...

Embodiment 3

[0026] A low-temperature dyeing process for polyester fibers, comprising the following steps:

[0027] 1. Dissolve benzyl alcohol, dimethyl phthalate, sorbitan monooleate polyoxyethylene ether, Yatrom blue AQE, and dispersant in a buffer solution with a pH value of 4.5-6.5 in sequence to prepare Dye liquor, and the temperature of dye liquor is raised to 50 ℃; the concentration of benzyl alcohol in the dye liquor is 5g / L, the concentration of dimethyl phthalate is 3g / L, sorbitan monooleate polyoxyethylene ether The concentration of the dispersant is 4g / L, and the concentration of the dispersant is 1.2g / L; the dosage of Artron Blue AQE is 2% owf;

[0028] The buffer solution is prepared with potassium dihydrogen phosphate and an appropriate amount of acetic acid; the dispersant is a mixture of sodium methylene dimethyl naphthalene sulfonate and alkaline sodium lignosulfonate at a mass ratio of 1:4;

[0029] 2. Put the polyester fabric into the dyeing solution with a liquor rati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com