Novel advanced wastewater treatment process for anaerobic system

A technology for advanced treatment of waste water, applied in anaerobic digestion treatment, filtration treatment, sedimentation treatment, etc., can solve the problems of increasing the load of aerobic system and sludge growth, affecting the quality of reused water, etc., to achieve energy saving and stable operation , The effect of saving production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

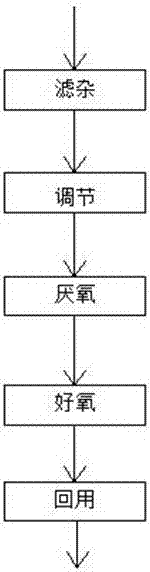

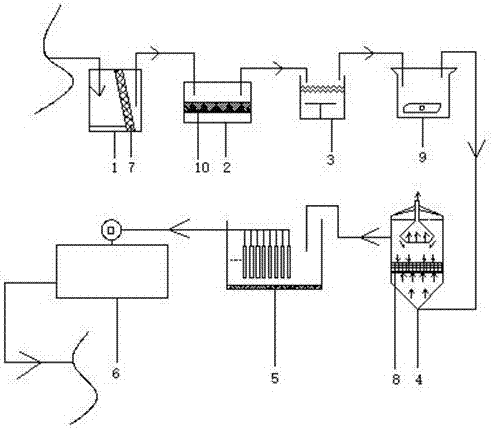

[0023] to combine figure 1 and figure 2 , the present invention proposes a kind of technology with pretreatment-anaerobic-aerobic advanced treatment papermaking wastewater, used novel IC reactor 4 and MBR sewage treatment equipment, comprises the following steps:

[0024] A. Filtration: The papermaking wastewater is pumped into the coarse grid tank 1, the fine grid tank 2, and the coagulation sedimentation tank 3 in sequence to remove impurities from large particles, small particles, colloids and flocs;

[0025] B. Adjustment: inject the filtered sewage into the adjustment tank 9, inject water and add urea and trisodium phosphate according to COD:N:P=350:5:1, and add sodium hydroxide to adjust the pH to 6.8~8.2;

[0026] C. Anaerobic: Inject the adjusted sewage from the lower end of the IC reactor 4, the reaction temperature is 30~40 degrees, and the tota...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com