Light-weighted high-intensity assembled wall

A high-strength, high-strength wall technology, applied in the field of building materials, can solve the problems of poor wall construction quality, harsh construction environment, water seepage, etc., to achieve convenient transportation and assembly applications, and good thickness controllability , good flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

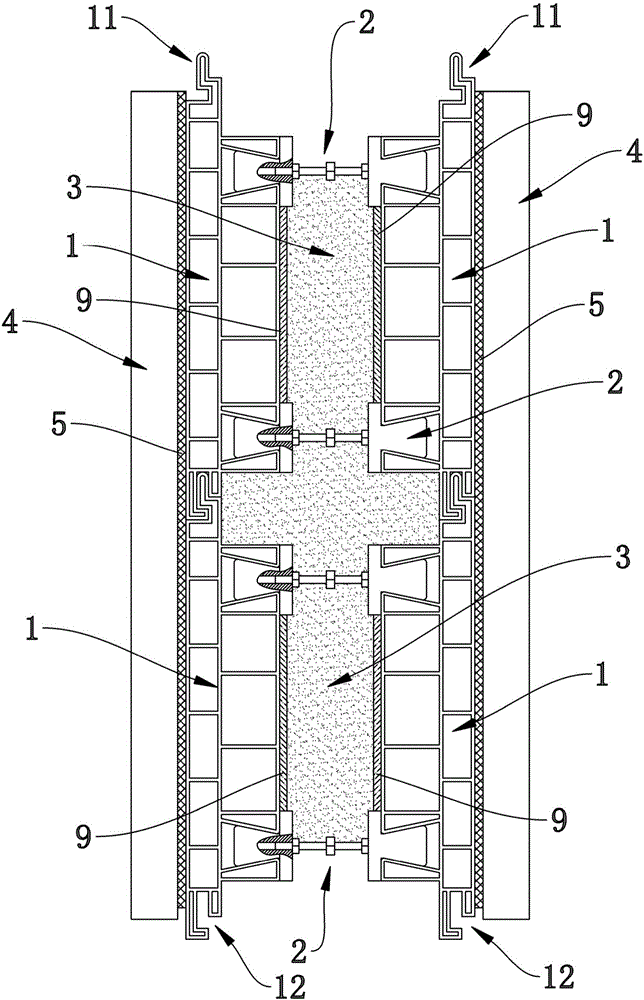

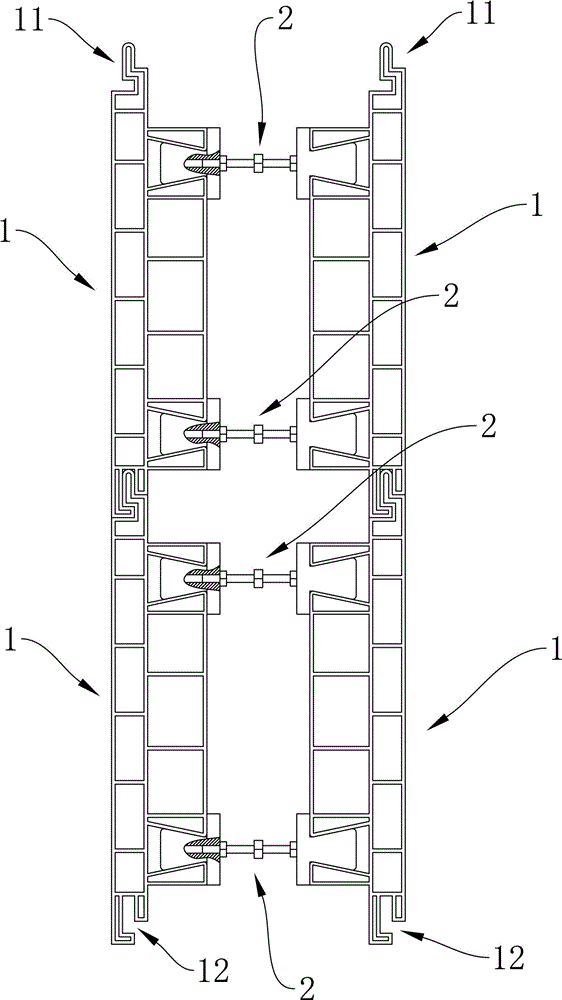

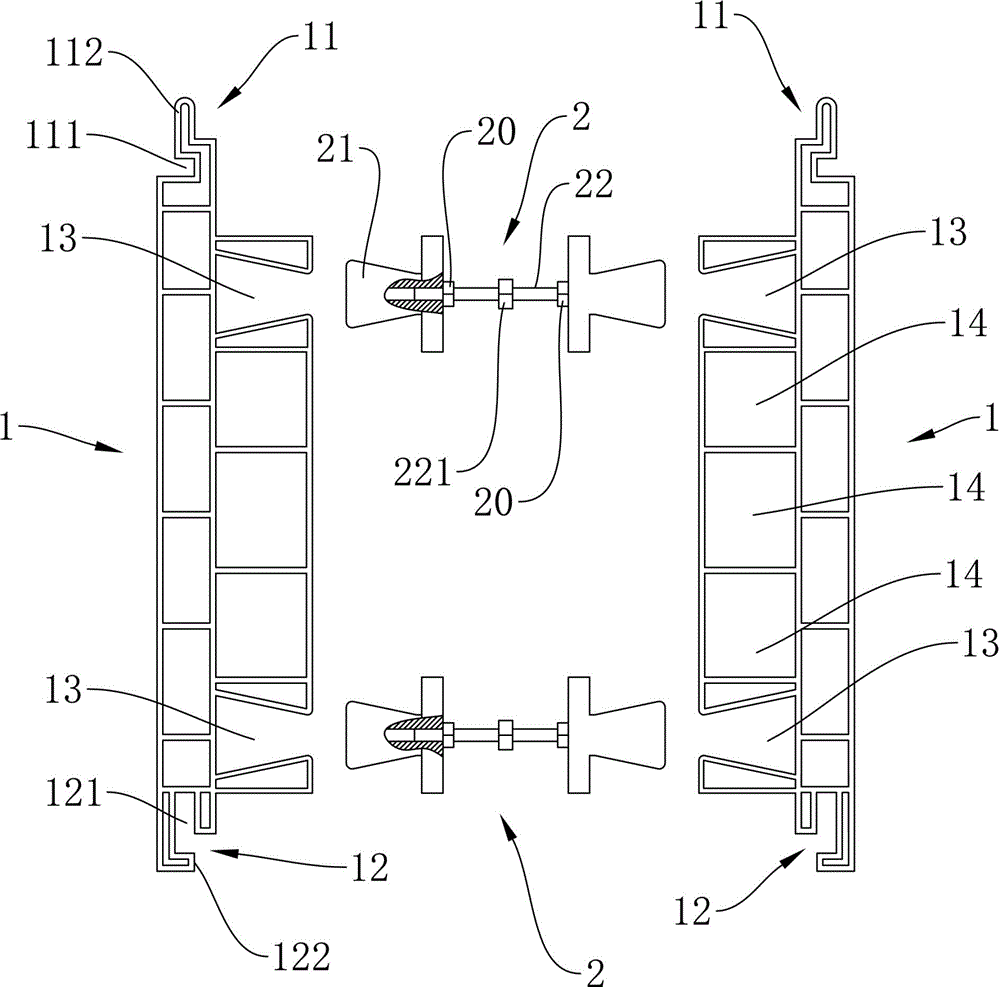

[0032] Such as figure 1 and figure 2 As shown, a light-weight and high-strength assembled wall of the present invention includes two hollow panels 1 arranged in parallel made of metal materials or plastic materials, an adjustable connection assembly 2, and a foam filling body 3 , wherein, the hollow plate body 1 can be made of aluminum alloy material or other alloy material or other metal material, and can be made of flame-retardant engineering plastic material.

[0033] Such as figure 1 , figure 2 As shown, the adjustable connection assembly 2 is connected and arranged between two hollow plates 1 to realize connecting the two hollow plates 1 and adjusting the distance between the two hollow plates 1 . Through such an arrangement, the thickness of the wall body of the present invention can be adjusted as required. The styrofoam filling body 3 is arranged in the gap between two hollow boards 1, and generally some flame retardants are added to the styrofoam material during...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com