High-speed electro-optical modulator and preparation method thereof

An electro-optical modulator and high-speed technology, applied in the field of optical communication, can solve the problems of low signal-to-noise ratio, slow modulation speed, and high cost of electro-optical modulators, and achieve high signal-to-noise ratio, low optical signal loss, and efficient and fast modulation speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A method for preparing a high-speed electro-optic modulator includes the following steps:

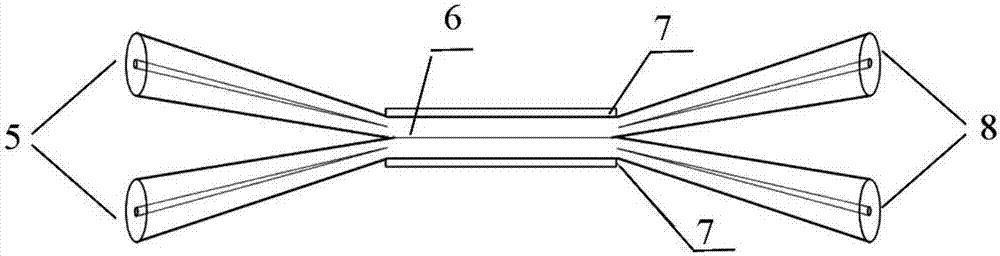

[0037] Step 1: Wind two SMF28 single-mode fibers together, put them into the fiber drawing platform and draw them into a micro-nano fiber coupler with a lateral width of 6μm;

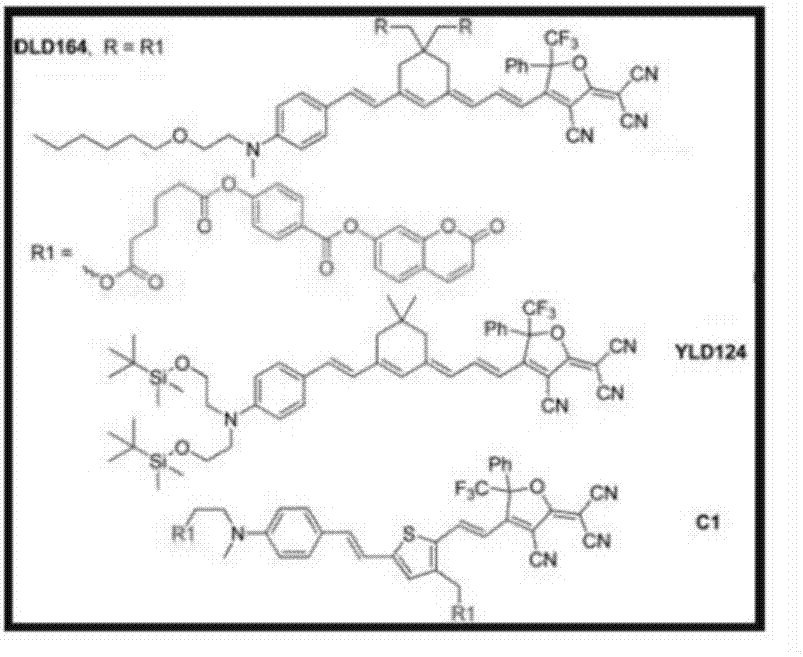

[0038] Step 2: Put the micro-nano fiber coupler into the second-order nonlinear light emitting group material layer (DLD164, R=R1) in acetone solution, and use the pulling coating method to coat the surface with a thickness of 200nm at a speed of 500mm / min The second-order nonlinear light emitting group material layer (DLD164, R=R1);

[0039] Step 3: Put the micro-nano fiber coupler coated with the second-order nonlinear light emitting group material layer (DLD164, R=R1) in the middle of the ITO electrode with a distance of 4mm for polarization, and the polarization voltage is 10000V, and the entire electrode Put the polarization device in a thermostat, heat the polarization device to 135°C, maintain the polariz...

Embodiment 2

[0042] A method for preparing a high-speed electro-optic modulator includes the following steps:

[0043] Step 1: Twist two SMF28 single-mode fibers together, put them into the fiber drawing platform and draw them into a micro-nano fiber coupler with a lateral width of 4μm;

[0044] Step 2. Put the micro-nano fiber coupler into the second-order nonlinear light emitting group material layer (DLD164, R=R1) in acetone solution, and use the pulling coating method to coat the surface with a thickness of 70nm at a speed of 100mm / min The second-order nonlinear light emitting group material layer (DLD164, R=R1);

[0045] Step 3: The micro-nano layer coated with the second-order nonlinear light emitting group material layer (DLD164, R=R1)

[0046] The fiber coupler is placed in the middle of the ITO electrode with a distance of 2mm for polarization, and the polarization voltage is 8000V. At the same time, the entire polarization device is placed in a thermostat, and the polarization device is ...

Embodiment 3

[0048] A method for preparing a high-speed electro-optic modulator includes the following steps:

[0049] Step 1: Twist two SMF28 single-mode fibers together, put them into the fiber drawing platform and draw them into a micro-nano fiber coupler with a lateral width of 3μm;

[0050] Step 2. Put the micro-nano fiber coupler into the second-order nonlinear light emitting group material layer (DLD164, R=R1) in acetone solution, and use the pulling coating method to coat the surface with a thickness of 120nm at a speed of 300mm / min The second-order nonlinear light emitting group material layer (DLD164, R=R1);

[0051] Step 3: The micro-nano layer coated with the second-order nonlinear light emitting group material layer (DLD164, R=R1)

[0052] The fiber coupler is placed in the middle of the ITO electrode with a distance of 3mm for polarization, and the polarization voltage is 900V. At the same time, the entire polarization device is placed in a thermostat, and the polarization device is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com