Preparation method of Bi2WO6 nano-sheets

A nanosheet and solution technology, which is applied in the field of preparation of Bi2WO6 nanosheets, can solve problems such as TiO2 has not had a major breakthrough, and achieve excellent photocatalytic performance, easy control, and stable product quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1) Dissolve 1.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.10mol / L;

[0035] 2) 3mmol ammonium bismuth citrate is dissolved in 15ml deionized water, so that the molar concentration of ammonium bismuth citrate solution is 0.20mol / L, and 0.10mmol of PVA is dissolved in 10ml deionized water;

[0036] Add the ammonium bismuth citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the PVA solution dropwise to the above mixed solution at the same rate, stir for 30 minutes, and then set the temperature at 180°C Insulated for 12 hours for heat treatment. Then, lower to room temperature, take out the reaction product, filter, wash with dilute acetic acid, deionized water and ethanol three times successively, and dry at 60°C to obtain Bi 2 WO 6 Nanosheets.

Embodiment 2

[0038] 1) Dissolve 3mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.20mol / L;

[0039] 2) Dissolve 6mmol bismuth ammonium citrate in 15ml deionized water, so that the molar concentration of bismuth ammonium citrate solution is 0.40mol / L; 0.25mmol PVA is dissolved in 10ml deionized water;

[0040] Add the ammonium bismuth citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the PVA solution dropwise to the above mixed solution at the same rate, stir for 30 minutes, and then set the temperature at 200°C Insulate for 20 hours for heat treatment. Then, lower to room temperature, take out the reaction product, filter, wash with dilute acetic acid, deionized water and ethanol three times successively, and dry at 60°C to obtain Bi 2 WO 6 Nanosheets.

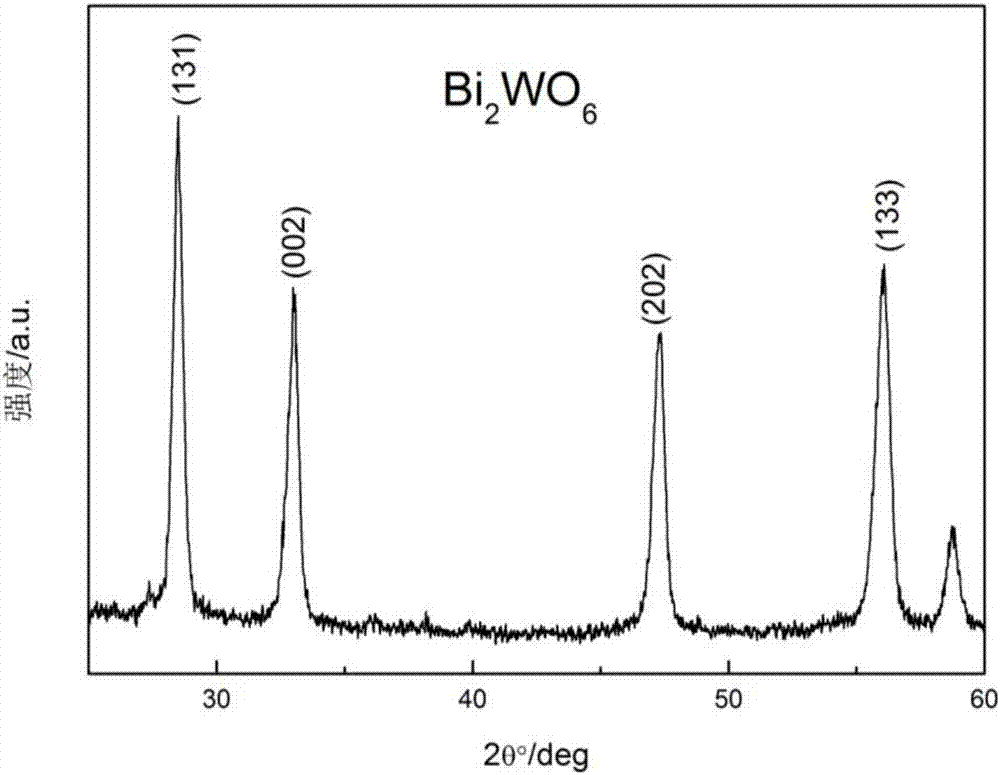

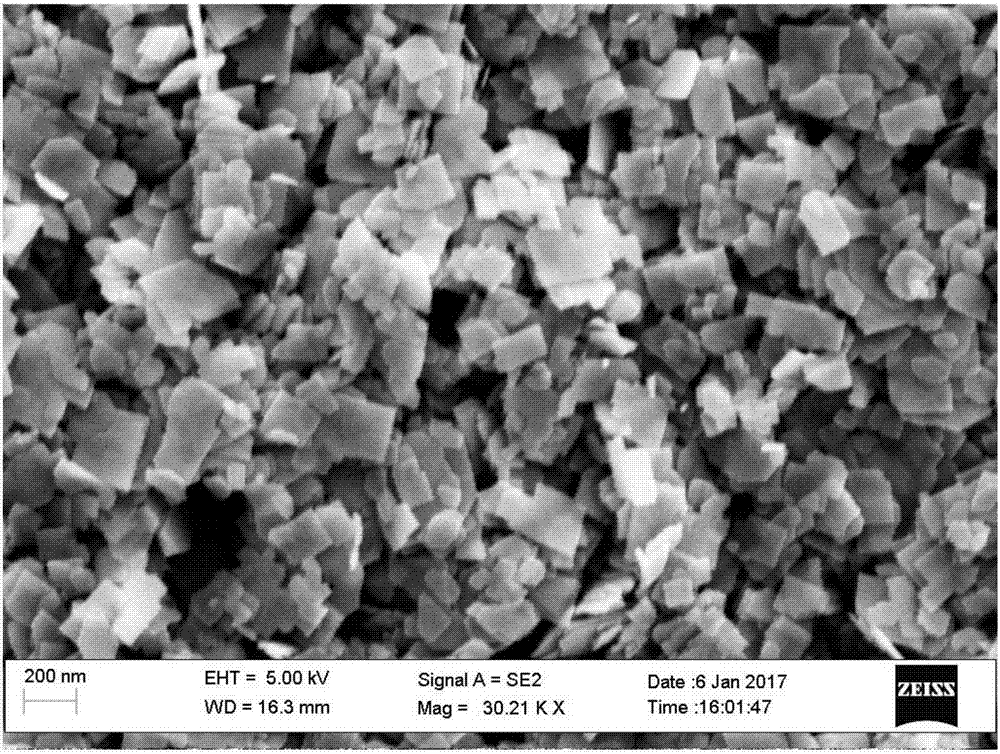

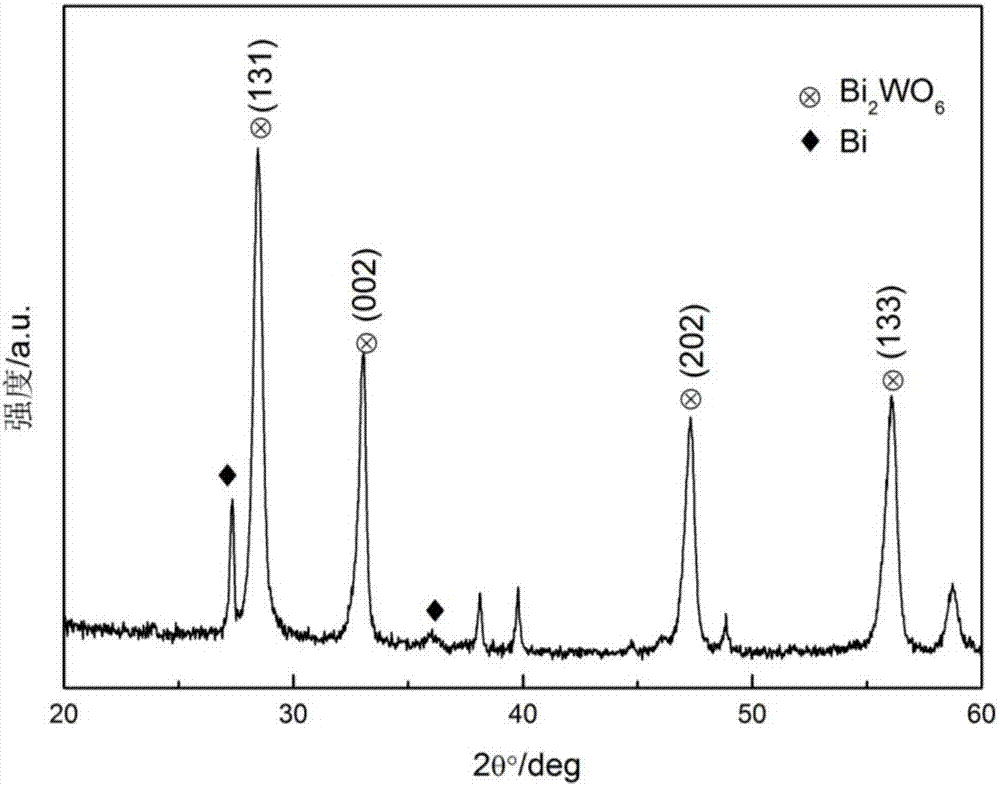

[0041] The synthesized Bi 2 WO 6 X-ray diffraction patterns of nanosheets, such as figure 1Shown; Sca...

Embodiment 3

[0043] 1) Dissolve 4.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.30mol / L;

[0044] 2) 9mmol of ammonium bismuth citrate is dissolved in 15ml of deionized water, so that the molar concentration of ammonium bismuth citrate solution is 0.60mol / L, and 0.5mmol of PVA is dissolved in 10ml of deionized water;

[0045] Add the ammonium bismuth citrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the PVA solution dropwise to the above mixed solution at the same rate, stir for 30 minutes, and then set the temperature at 250°C Insulated for 32 hours for heat treatment. Then, lower to room temperature, take out the reaction product, filter, wash with dilute acetic acid, deionized water and ethanol three times successively, and dry at 60°C to obtain Bi 2 WO 6 Nanosheets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com