Preparation method of Bi2WO6 nano-spheres

A technology of nanospheres and solutions, applied in the field of preparation of Bi2WO6 nanospheres, which can solve problems such as increased valence band potential and narrowed forbidden band width, and achieves the effects of easy control, low cost and stable product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

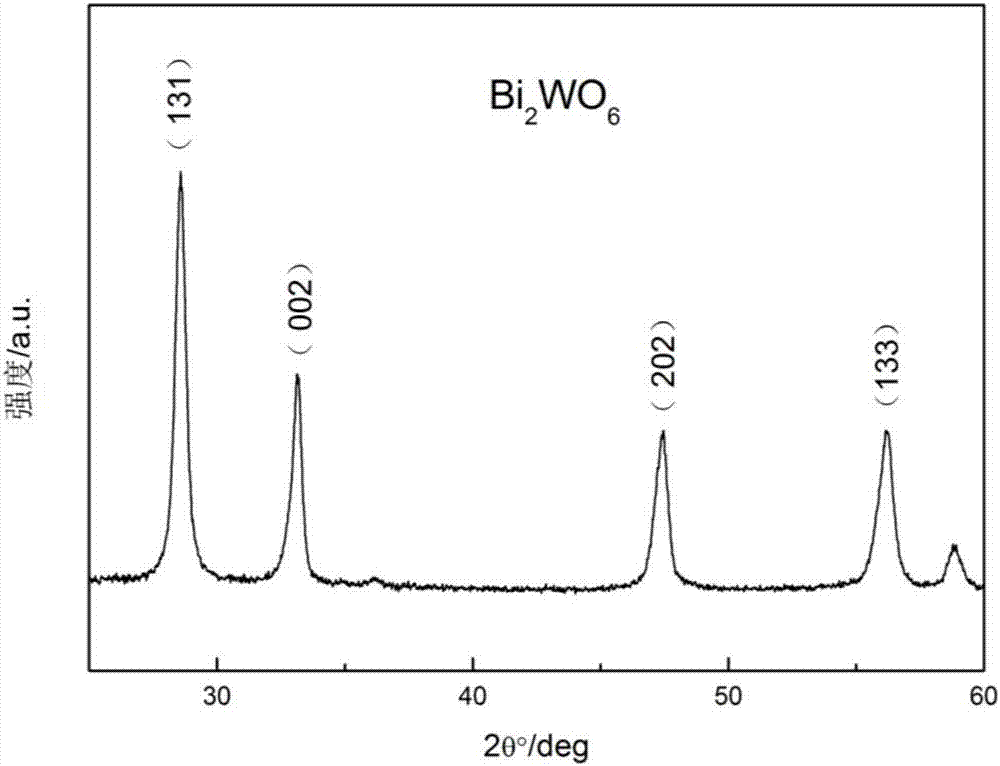

Embodiment 1

[0032] 1) Dissolve 1.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.10mol / L;

[0033] 2) 3mmol bismuth nitrate pentahydrate was dissolved in 15ml deionized water, so that the molar concentration of bismuth nitrate pentahydrate solution was 0.20mol / L, and 0.10mmol tetramethylammonium hydroxide was dissolved in 10ml deionized water;

[0034] Then add the bismuth nitrate pentahydrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the tetramethylammonium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes Afterwards, heat treatment was carried out at 180° C. for 12 hours. Then, after cooling down to room temperature, the reaction product was taken out, filtered, washed with dilute acetic acid, deionized water and ethanol in turn, and dried at 60°C to obtain Bi 2 WO 6 nanospheres.

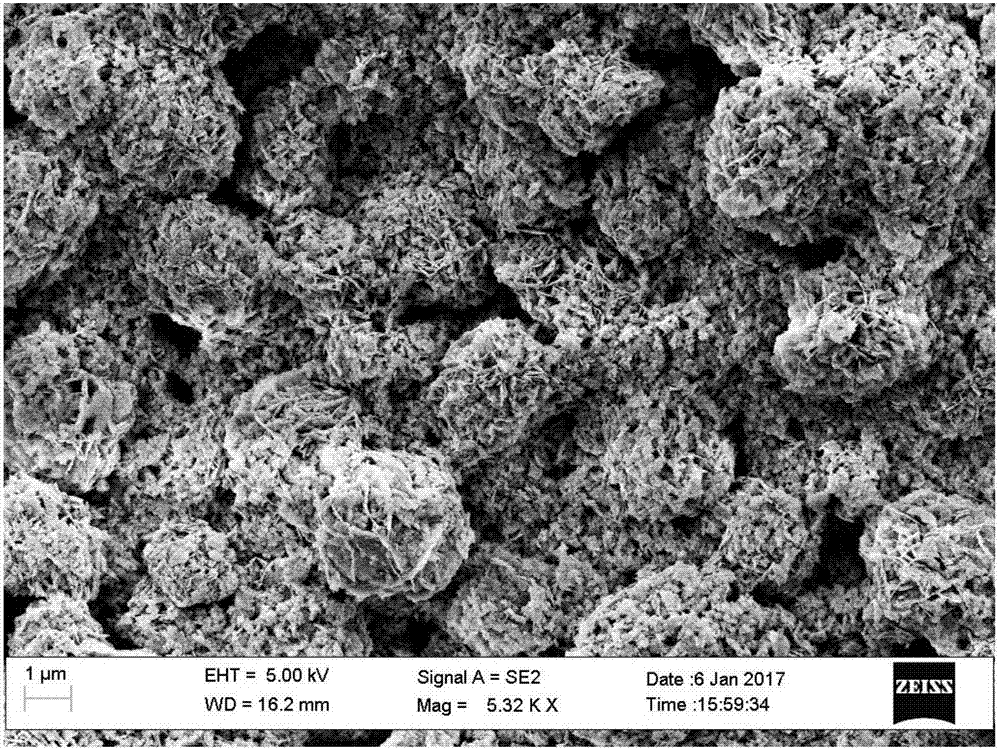

Embodiment 2

[0036] 1) Dissolve 3mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.20mol / L;

[0037] 2) 6mmol bismuth nitrate pentahydrate was dissolved in 15ml deionized water, so that the molar concentration of bismuth nitrate pentahydrate solution was 0.40mol / L, and 0.25mmol tetramethylammonium hydroxide was dissolved in 10ml deionized water;

[0038] Then add the bismuth nitrate pentahydrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the tetramethylammonium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes After that, heat treatment was performed by keeping the temperature at 200° C. for 20 hours. Then, after cooling down to room temperature, the reaction product was taken out, filtered, washed with dilute acetic acid, deionized water and ethanol in turn, and dried at 60°C to obtain Bi 2 WO6 nanospheres.

[0...

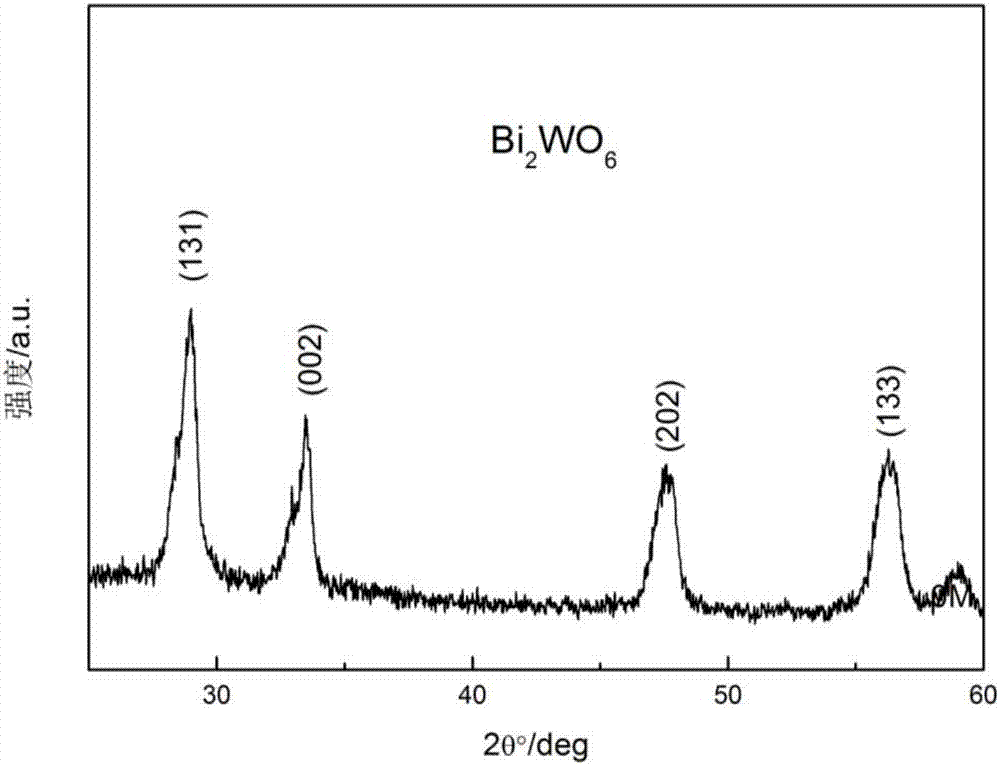

Embodiment 3

[0041] 1) Dissolve 4.5mmol sodium tungstate dihydrate in 15ml deionized water, so that the molar concentration of sodium tungstate dihydrate solution is 0.30mol / L;

[0042] 2) 9mmol bismuth nitrate pentahydrate was dissolved in 15ml deionized water, so that the molar concentration of bismuth nitrate pentahydrate solution was 0.60mol / L, and then 0.5mmol tetramethylammonium hydroxide was dissolved in 10ml deionized water;

[0043] Add the bismuth nitrate pentahydrate solution dropwise to the sodium tungstate solution at a rate of 1-2 drops / second, and add the tetramethylammonium hydroxide solution dropwise to the above mixed solution at the same rate, and stir for 30 minutes , Heat treatment at 250°C for 32 hours. Then, after cooling down to room temperature, the reaction product was taken out, filtered, washed with dilute acetic acid, deionized water and ethanol in turn, and dried at 60°C to obtain Bi 2 WO 6 nanospheres.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com