Moisture absorption prevention thermal-insulating interlayer glass and preparation method thereof

A technology of laminated glass and double-layer glass, which is applied in the field of anti-moisture absorption and heat insulation laminated glass and its preparation, which can solve the problems of affecting the interlayer, generating water mist, moisture absorption, etc., and achieves good moisture-proof and heat-insulating performance and good heat insulation Performance, the effect of meeting the heat insulation requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

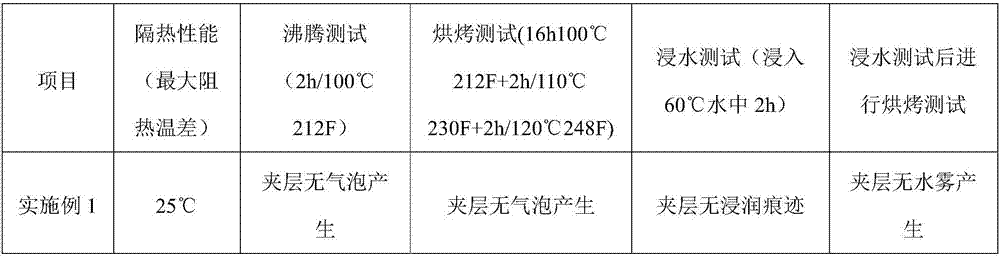

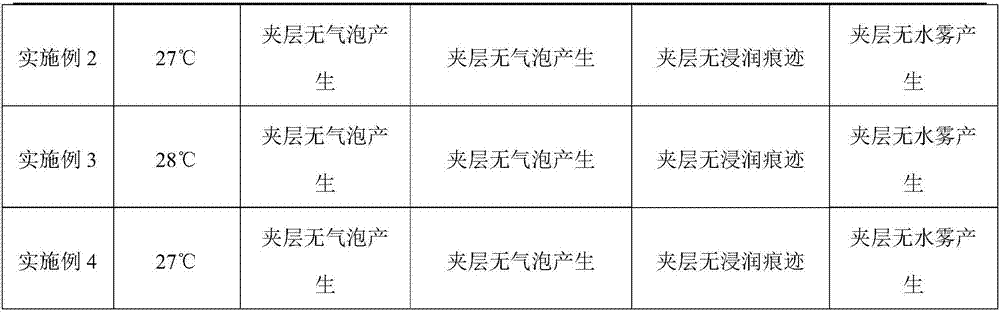

Examples

Embodiment 1

[0023] An anti-moisture absorption and heat-insulating laminated glass, comprising double-layer glass and a heat-insulating laminated film arranged between the double-layered glasses, the heat-insulating laminated film contains modified heat-insulating film in parts by weight 60 parts of binder, 1 part of hindered phenolic antioxidant and 2 parts of barium sulfate;

[0024] The modified heat-insulating adhesive is made of the following components by weight: 3 parts of polyethylene, 5 parts of polyurethane resin, 0.2 parts of emulsified silicone oil, 6 parts of silicone epoxy resin, and 30 parts of polyvinyl butyral , 1 part of nano-silica, 5 parts of heat-insulating particle ATO, 1 part of cellulose ether, 0.1 part of ultrafine zinc powder, 8 parts of isopropanol, 0.5 part of o-hydroxybenzophenone UV absorber and dimethyl 0.5 parts of butylene glycol acrylate.

[0025] The preparation method of the above modified thermal insulation adhesive is as follows:

[0026] Step 1, st...

Embodiment 2

[0033] An anti-moisture absorption and heat-insulating laminated glass, comprising double-layer glass and a heat-insulating laminated film arranged between the double-layered glasses, the heat-insulating laminated film contains modified heat-insulating film in parts by weight 63 parts of binder, 1 part of hindered phenolic antioxidant and 3 parts of barium sulfate;

[0034] The modified heat-insulating adhesive is made of the following components by weight: 4 parts of polyethylene, 6 parts of polyurethane resin, 0.3 parts of emulsified silicone oil, 7 parts of silicone epoxy resin, and 32 parts of polyvinyl butyral , 2 parts of nano-silicon dioxide, 6 parts of heat-insulating particles ITO, 2 parts of cellulose ether, 0.2 parts of ultra-fine zinc powder, 9 parts of isopropanol, 0.6 parts of o-hydroxybenzophenone UV absorber and dimethyl 0.7 parts of butylene glycol acrylate.

[0035] The preparation method of the above modified thermal insulation adhesive is as follows:

[0...

Embodiment 3

[0043] An anti-moisture absorption and heat-insulating laminated glass, comprising double-layer glass and a heat-insulating laminated film arranged between the double-layered glasses, the heat-insulating laminated film contains modified heat-insulating film in parts by weight 68 parts of binder, 2 parts of hindered phenolic antioxidant and 3 parts of barium sulfate;

[0044] The modified heat-insulating adhesive is made of the following components by weight: 5 parts of polyethylene, 8 parts of polyurethane resin, 0.4 parts of emulsified silicone oil, 7 parts of silicone epoxy resin, and 33 parts of polyvinyl butyral , 2 parts of nano-silica, 8 parts of heat-insulating particles AZO, 3 parts of cellulose ether, 0.2 parts of ultrafine zinc powder, 11 parts of isopropanol, 0.7 parts of o-hydroxybenzophenone UV absorber and dimethyl 0.8 parts of butylene glycol acrylate.

[0045] The preparation method of the above modified thermal insulation adhesive is as follows:

[0046] Ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com