Carbon fiber parallel electric tracing band

A technology of electric heating cable and carbon fiber, which is applied in the direction of circuits, insulated cables, electrical components, etc., can solve the problems of low tension of heating wire, high surface load of heating wire, busbar overturning, etc., achieve strong high temperature oxidation resistance, and avoid carbon fiber breakage , the effect of ensuring personal safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

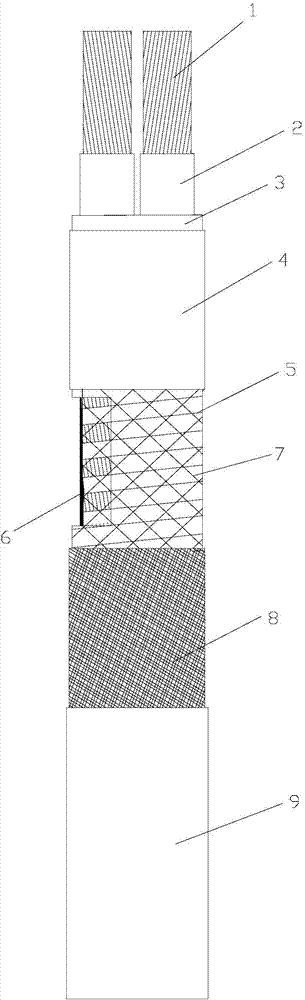

[0017] Such as figure 1 The shown carbon fiber parallel electric heating cable includes two busbars 1 arranged in parallel, each busbar is coated with a fluoroplastic insulating layer 2, and the periphery of the two busbars is coated with a fluoroplastic combined layer 3, and the fluoroplastic combined layer 3 is covered with carbon fiber 5, and the exterior of carbon fiber 5 is provided with a high-temperature resistant fiber braided layer 7, and the outer periphery of the high-temperature resistant fiber braided layer 7 is covered with a fluoroplastic inner sheath 4, and the outer periphery of the fluoroplastic inner sheath 4 is coated with a Tin-copper braided mesh 8, the periphery of the tinned copper braided mesh 8 is covered with a fluoroplastic outer sheath 9, and the combined busbar is provided with gaps at intervals of 0.8-2.5m on one side, and the fluoroplastic insulation at the gaps Both layers and fluoroplastic merged layers are peeled off, and the contact part of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com