Preparation method of temperature buffer type polyvinyl alcohol film

A technology of polyvinyl alcohol film and polyvinyl alcohol, applied in the field of packaging materials, to achieve the effects of easy control of film making process, increase of temperature buffer performance, and guarantee of nutritional value and commodity value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] (1) Preparation of polyvinyl alcohol adhesive film:

[0030] Weigh 24g of PVA and place it in a beaker. Add 200ml of deionized water to the beaker and place it in a counter-pressure high-temperature cooking pot for 50 minutes at 121°C. After the temperature in the cooking pot drops to 90°C, take out the beaker and use a glass rod to fully stir for 5 minutes , Placed in a heat-collecting thermostatic heating magnetic stirrer at 90℃, adjust the speed to 50rpm and stir for 30 minutes, use a pipette to add 1ml glycerin as a plasticizer while magnetic stirring in a water bath, continue stirring for 30 minutes, and finally obtain PVA Mother liquor, the PVA mother liquor solution is cast on a glass plate, the glass plate is 30×30cm, the temperature of the glass plate is 60℃, and the temperature of the glass plate is kept unchanged. After standing for 20 minutes, a viscous polyvinyl alcohol film is obtained for use;

[0031] (2) Preparation of polycaprolactone / liquid paraffin electr...

Embodiment 1

[0040] Weigh 24g of PVA and place it in a beaker. Add 200ml of deionized water to the beaker and place it in a counter-pressure high-temperature cooking pot for 50 minutes at 121°C. After the temperature in the cooking pot drops to 90°C, take out the beaker and use a glass rod to fully stir for 5 minutes , Placed in a heat-collecting thermostatic heating magnetic stirrer at 90℃, adjust the speed to 50rpm and stir for 30 minutes, use a pipette to add 1ml glycerin as a plasticizer while magnetic stirring in a water bath, continue stirring for 30 minutes, and finally obtain PVA The mother liquor, the PVA mother liquor solution is cast on a glass plate, the glass plate is 30×30cm, the temperature of the glass plate is 60℃, the temperature of the glass plate is kept unchanged, and the polyvinyl alcohol film is obtained after standing for 50 minutes. Vacuum and seal in a high-barrier bag for storage at 4℃.

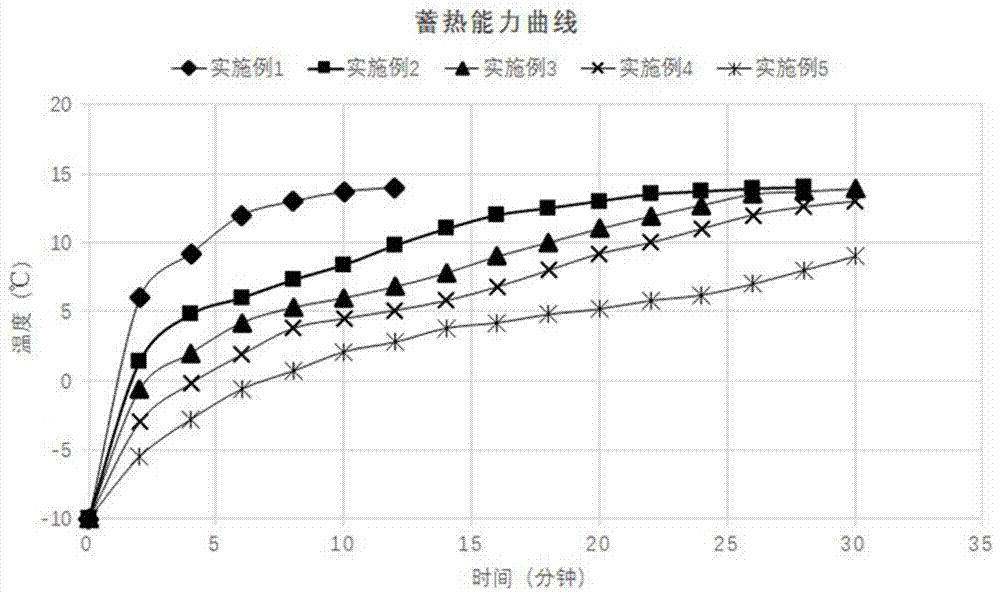

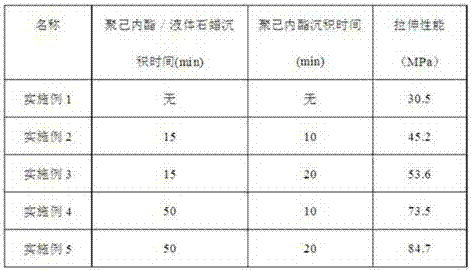

[0041] Determine the mechanical properties and heat storage capacity of the fi...

Embodiment 2

[0043] Weigh 24g of PVA and place it in a beaker. Add 200ml of deionized water to the beaker and place it in a counter-pressure high-temperature cooking pot for 50 minutes at 121°C. After the temperature in the cooking pot drops to 90°C, take out the beaker and use a glass rod to fully stir for 5 minutes , Placed in a heat-collecting thermostatic heating magnetic stirrer at 90℃, adjust the speed to 50rpm and stir for 30 minutes, use a pipette to add 1ml glycerin as a plasticizer while magnetic stirring in a water bath, continue stirring for 30 minutes, and finally obtain PVA The mother liquor, the PVA mother liquor solution is cast on a glass plate, the glass plate is 30×30 cm, the temperature of the glass plate is 60°C, the temperature of the glass plate is kept unchanged, and the viscous polyvinyl alcohol film is obtained after standing for 20 minutes, which is ready for use.

[0044] Weigh 75ml of chloroform and place it in a beaker, then add 25ml of N,N-dimethylformamide to it...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com