Treatment method of oil-based drilling cuttings and oily sludge

A technology of oil-based drilling cuttings and treatment method, which is applied in sludge treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc., can solve the problems of high treatment cost and expensive extraction agent, etc. Achieve a wide range of applications, high recycling efficiency, and reduce environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

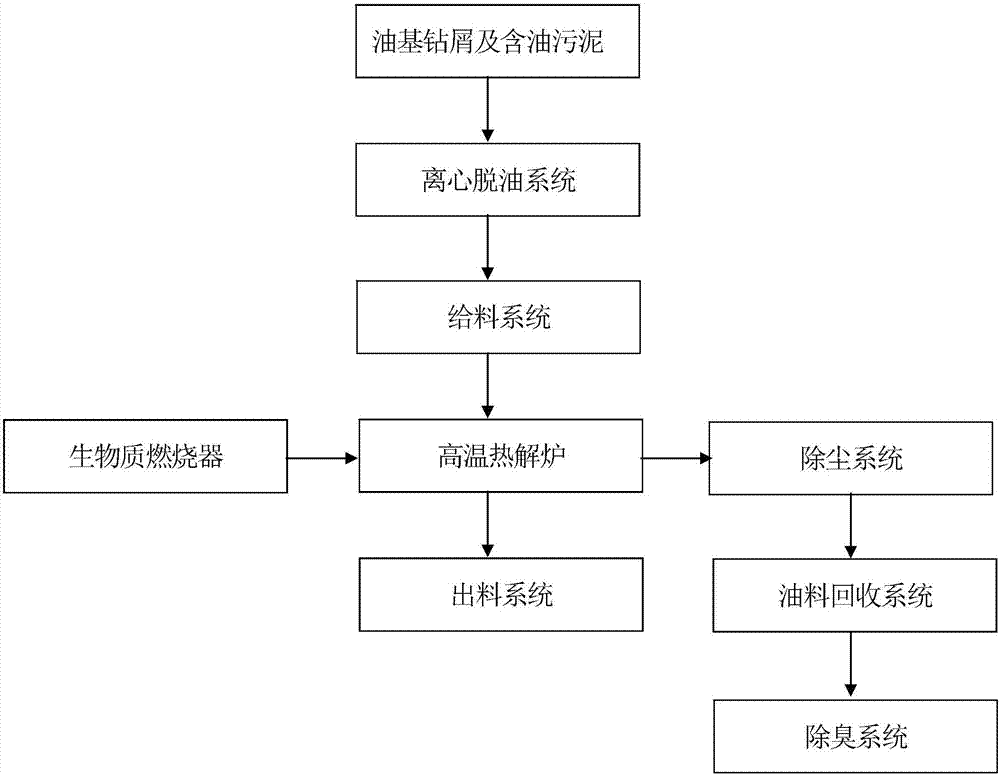

[0034] in figure 1 In the present invention, the method for treating oil-based drill cuttings and oily sludge consists of the following steps:

[0035] 1). Transport oil-based drilling cuttings and oily sludge to the centrifugal deoiling system for deoiling; the drilling cuttings and oily sludge processed by the centrifugal deoiling system enter the high-temperature pyrolysis furnace from the feeding system, and more than 80% of the Oil-based mud is recycled and reused; the centrifugal de-oiling system described in this embodiment is a centrifugal de-oiling machine, and the feeding method of the feeding system adopts the circulating exhaust feeding method, which can ensure the air lock effect and ensure the continuity of feeding. Uniformity.

[0036] 2) The processed oil-bearing drilling cuttings are pyrolyzed and vaporized in the high-temperature pyrolysis furnace; the biomass burner generates high-temperature hot air to supply the heat of the high-temperature pyrolysis furnace; ...

Embodiment 2

[0044] In embodiment 1, step 2) of this embodiment, the processed oil-bearing drilling cuttings are pyrolyzed and vaporized in the high-temperature pyrolysis furnace; the biomass burner generates high-temperature hot air to supply the heat of the high-temperature pyrolysis furnace; the drilling cuttings are in The conditions for pyrolysis and vaporization in the high-temperature pyrolysis furnace include: a temperature of 260°C, an oxygen-free negative pressure value of 7MPa, and a time of 2h. The rest of the steps are exactly the same as in Example 1.

Embodiment 3

[0046] In embodiment 1, step 2) of this embodiment, the processed oil-bearing drilling cuttings are pyrolyzed and vaporized in the high-temperature pyrolysis furnace; the biomass burner generates high-temperature hot air to supply the heat of the high-temperature pyrolysis furnace; the drilling cuttings are in The conditions for pyrolysis and vaporization in the high-temperature pyrolysis furnace include: a temperature of 1150°C, an oxygen-free negative pressure value of 35MPa, and a time of 48h. The rest of the steps are exactly the same as in Example 1.

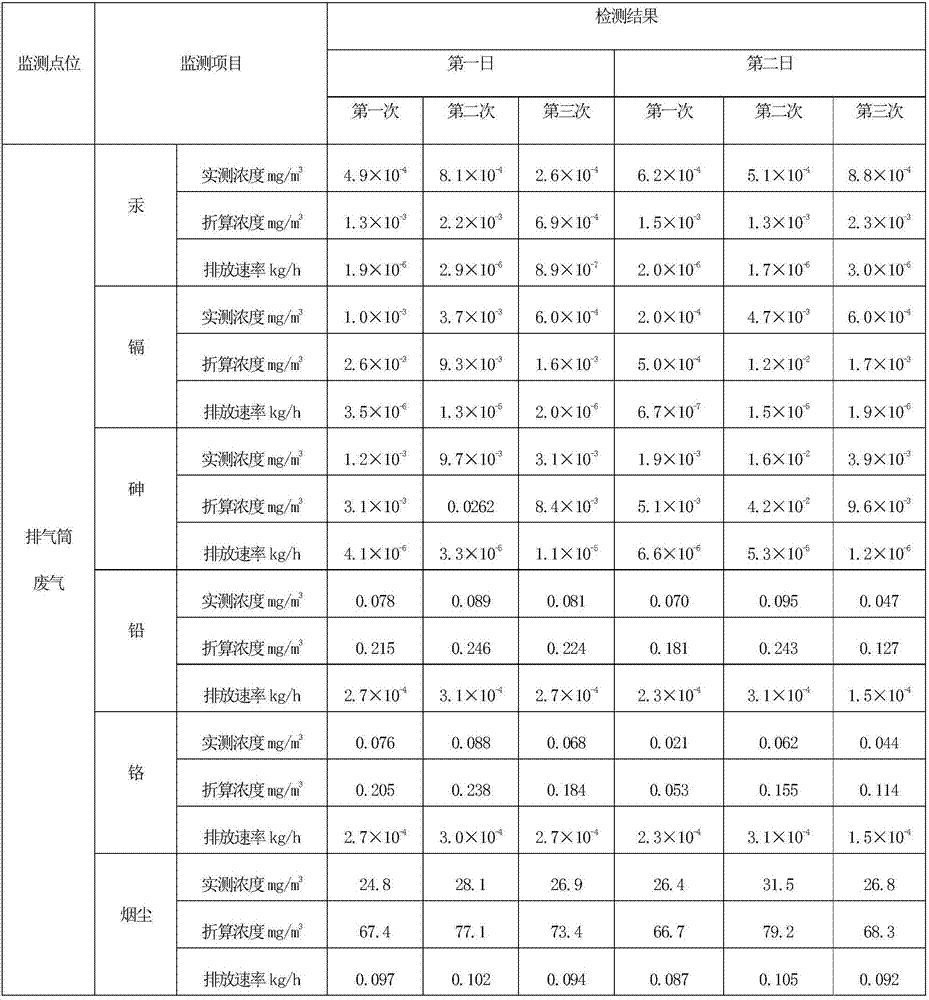

[0047] Tables 1, 2, and 3 are the data of each monitoring item of the exhaust gas from the exhaust tube treated by the treatment method of the present invention, and Tables 4-8 are the data of each detection item of the mud and mud cake treated by the treatment method of the present invention.

[0048] Table 1 Exhaust gas from exhaust pipe

[0049]

[0050]

[0051] Table 2 Exhaust gas from exhaust pipe

[0052]

[0053] Table 3 E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com