Cleaning agent and preparation method and application thereof

A cleaning agent and extract technology, applied in the direction of biochemical equipment and methods, preparation of detergent mixture compositions, chemical instruments and methods, etc., can solve problems such as environmental pollution, insufficient cleaning ability of cleaning agents, human hazards, etc., to achieve The effect of improving extraction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

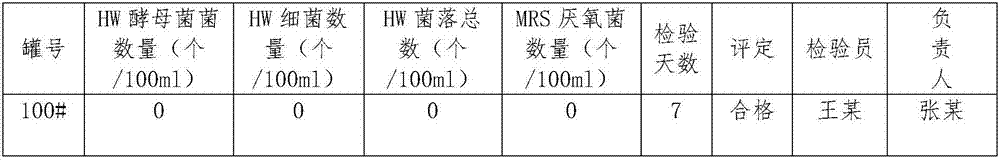

[0045] Embodiment 1: beer fermentation tank cleaning agent

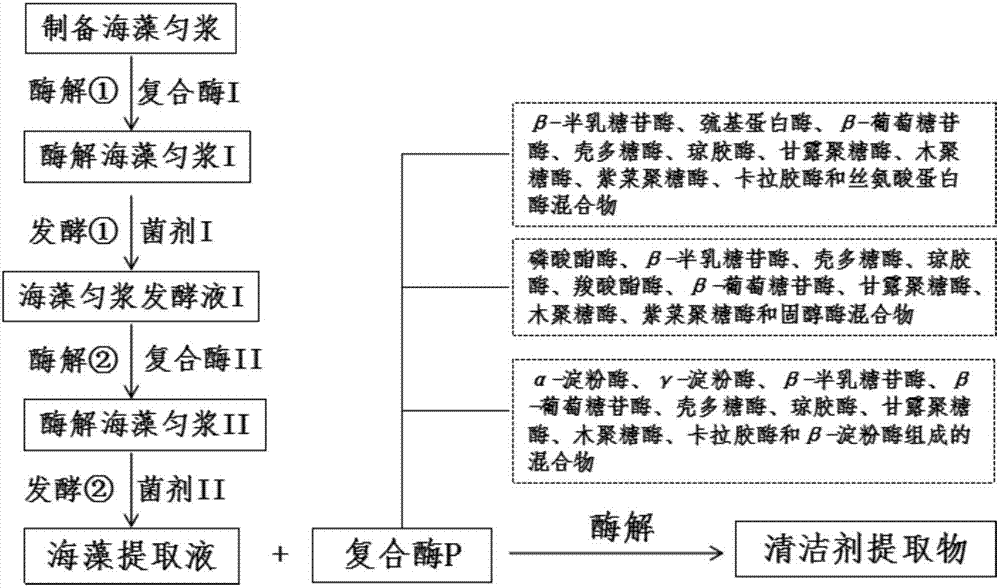

[0046] 1. Production process of detergent extract

[0047] 1. Preparation of seaweed extract

[0048] 1.1 Preparation of seaweed homogenate: fresh seaweed (ascophyllum nodosum, sargassum, brown algae, fucus, dulse palmiformis, sea sac algae, etc. are mixed): water is ground according to the mass ratio 1: (0.2~0.3), Make a homogenate and refrigerate at 3-6°C for later use.

[0049] 1.2 Enzyme hydrolysis ①: add compound enzyme I according to 0.2-0.5% of the quality of seaweed homogenate obtained above (compound enzyme I is a mixture of pectin hydrolase, proteolytic enzyme and cellulase, and the ratio of dosage is 1:1: ( 2~3)), adjust pH 6~7, temperature 30~50°C, enzymolysis reaction 48~72h, obtain enzymolysis seaweed homogenate I.

[0050] 1.3 Fermentation①

[0051] 1.3.1 Cultivation of bacterial agent I: take one ring of slant strains, inoculate Bacillus subtilis in liquid medium a, inoculate lactic acid bacteria ...

Embodiment 2

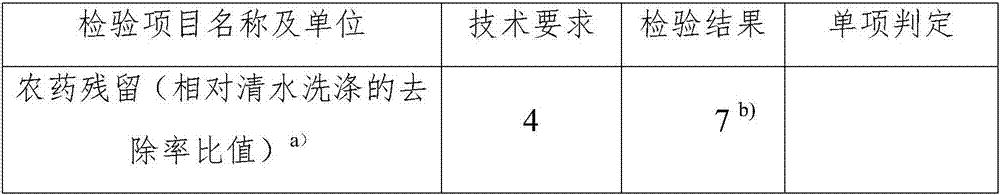

[0094] Embodiment 2: fruits and vegetables remove pesticide residue cleaning agent

[0095] 1. Cleaning agent production process

[0096] 1. Preparation of seaweed extract

[0097] 1.1 Preparation of seaweed homogenate: fresh seaweed (ascophyllum nodosum, sargassum, brown algae, fucus, dulse palmiformis, sea sac algae, etc. are mixed): water is ground according to the mass ratio 1: (0.2~0.3), Make a homogenate and refrigerate at 3-6°C for later use.

[0098] 1.2 Enzyme hydrolysis ①: add compound enzyme I according to 0.2-0.5% of the quality of seaweed homogenate obtained above (compound enzyme I is a mixture of pectin hydrolase, proteolytic enzyme and cellulase, and the ratio of dosage is 1:1: ( 2~3)), adjust pH 6~7, temperature 30~50°C, enzymolysis reaction 72h, obtain enzymolysis seaweed homogenate I.

[0099] 1.3 Fermentation①

[0100] 1.3.1 Cultivation of bacterial agent I: Take a ring of slant strains, inoculate Bacillus subtilis in liquid medium a, inoculate lactic a...

Embodiment 3

[0120] Embodiment 3: antibacterial hand sanitizer

[0121] 1. Production process of detergent extract

[0122] 1. Preparation of seaweed extract

[0123] 1.1 Preparation of seaweed homogenate: fresh seaweed (ascophyllum nodosum, sargassum, brown algae, fucus, dulse palmiformis, sea sac algae, etc. are mixed): water is ground according to the mass ratio 1: (0.2~0.3), Make a homogenate and refrigerate at 3-6°C for later use.

[0124] 1.2 Enzyme hydrolysis ①: add compound enzyme I according to 0.2-0.5% of the quality of seaweed homogenate obtained above (compound enzyme I is a mixture of pectin hydrolase, proteolytic enzyme and cellulase, and the ratio of dosage is 1:1: ( 2~3)), adjust pH 6~7, temperature 30~50°C, enzymolysis reaction 72h, obtain enzymolysis seaweed homogenate I.

[0125] 1.3 Fermentation①

[0126] 1.3.1 Cultivation of bacterial agent I: Take a ring of slant strains, inoculate Bacillus subtilis in liquid medium a, inoculate lactic acid bacteria in liquid medi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com