Polyarylene sulfide composition with excellent adhesion to metal

A technology of polyarylene sulfide and composition, applied in the field of polyarylene sulfide composition, can solve the problems of weakening the thermal properties of PPS, reducing the mechanical properties of PPS, etc., and achieving excellent mechanical properties and thermal properties, and excellent metal adhesion. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0076] Preparation Example 1: Preparation of PPS

[0077] 40 kg of p-diiodobenzene, 3.4 kg of sulfur and 150 g of 1,3-diiodo-4-nitrobenzene as a catalyst were melt blended in a reactor at 180°C. The mixed reactants were polymerized while increasing the temperature from 180°C to 340°C and decreasing the pressure from 350 Torr to 10 Torr. 5 hours after the start of the polymerization, 150 g of sulfur and 100 g of diphenyl sulfide as a polymerization terminator were added to the reaction mixture, and the polymerization reaction was further carried out for 3 hours to obtain a polymer.

[0078] The melt viscosity (MV), melting point (Tm) and weight ratio of the repeating unit of the resulting PPS polymer were determined according to the following methods. The results showed that the MV of the PPS polymer was 2000 poise, the Tm was 280°C, the number average molecular weight was 16,400, and the weight ratio of the arylene sulfide unit to the arylene disulfide unit was 1:0.003.

[0...

Embodiment 1

[0085] Embodiment 1: the preparation of PPS resin composition

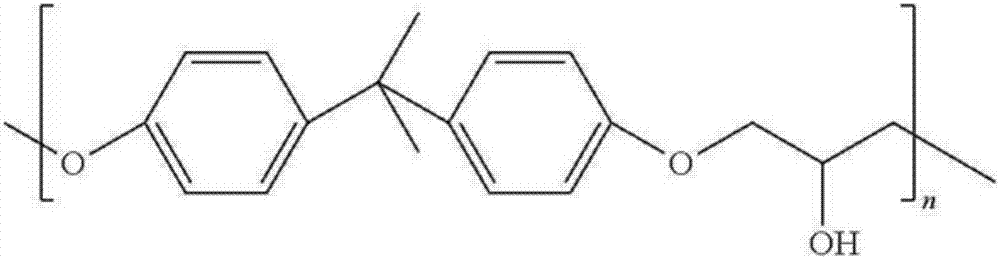

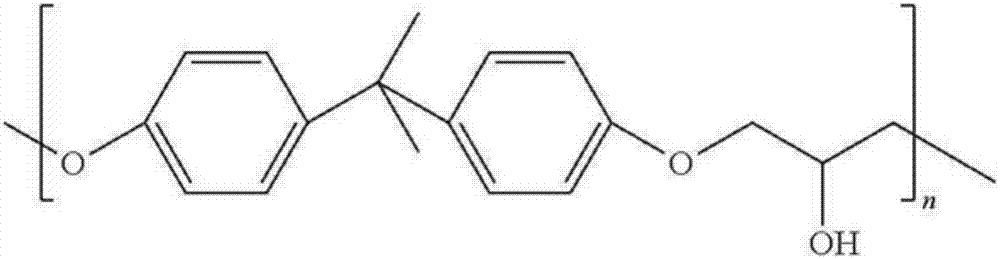

[0086] With 67% (weight) of PPS resin obtained in Preparation Example 1, 15% (weight) of epoxy silane (OCV-910, Owens Corning) process glass fiber, 8% (weight) of elastomer (Lotader AX- 8900, Arkema), 5% (weight) of phenoxy resin (YP-50, Kukdo Chemical company) and 5% (weight) of white pigment TiO 2 (Grade 2233, Kronoss) was fed into a twin screw extruder to prepare the composition.

[0087] The diameter of the extruder is 40mm, L / D is 44 (SM Platek). The extrusion conditions were a screw speed of 250 rpm, a feed rate of 60 kg / hour, a barrel temperature of 280-300° C. and a torque of 60%. The above materials are fed through three feeders in total, among which the first feeder is used to feed PPS resin, elastomer and phenoxy resin, the second feeder is used to feed white pigment, and the third feeder The device is used to feed glass fiber.

Embodiment 2-7

[0089] Repeat the same steps as in Example 1 to prepare the PPS resin composition, except that the components and their amounts are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com