A kind of method for preparing rosin-lac ester by solid phase reaction

A technology for solid-phase reaction and esterification, which is applied in the field of mechanical grinding solid-phase reaction to prepare rosin-shellac esterification, can solve the problems of solvent pollution, high temperature and high energy consumption, etc., to avoid self-polymerization, solve high temperature, high energy consumption, and low energy consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0026] The preparation method comprises the steps of:

[0027] a. Mechanical grinding: Weigh shellac equivalent to 10-25% of the molar mass of rosin adduct and mix it with rosin adduct, add catalyst equivalent to 0.1% of rosin adduct mass, mix evenly, put into grinding tank, Add zirconia grinding balls of the same quality as the material; put the grinding tank into the ball mill, grind for 80-160 minutes at room temperature, and the ball mill speed is 250 rpm; separate the product from the grinding balls; the catalyst can be ZnO, Catalysts such as MgO, CaO, and solid superacids.

[0028] The dosage of the shellac is 10-25% of the molar mass of the rosin adduct.

[0029] The speed of the ball mill is 250 rpm, and the grinding time is 80-160 minutes.

[0030] b. Annealing reaction: place the ground material in a constant temperature blast drying oven, react at 60-100°C for 6-12h, and cool to room temperature with the furnace after the reaction;

[0031] The annealing reaction...

Embodiment 1

[0039] A method for preparing rosin-lac esters by solid phase reaction, comprising the steps of:

[0040] The first step, the preparation of rosin adduct: Weigh 100g of rosin, raise the temperature to 170°C, stir, slowly add 30g of maleic anhydride, and react at 195°C for 3h to obtain maleated rosin.

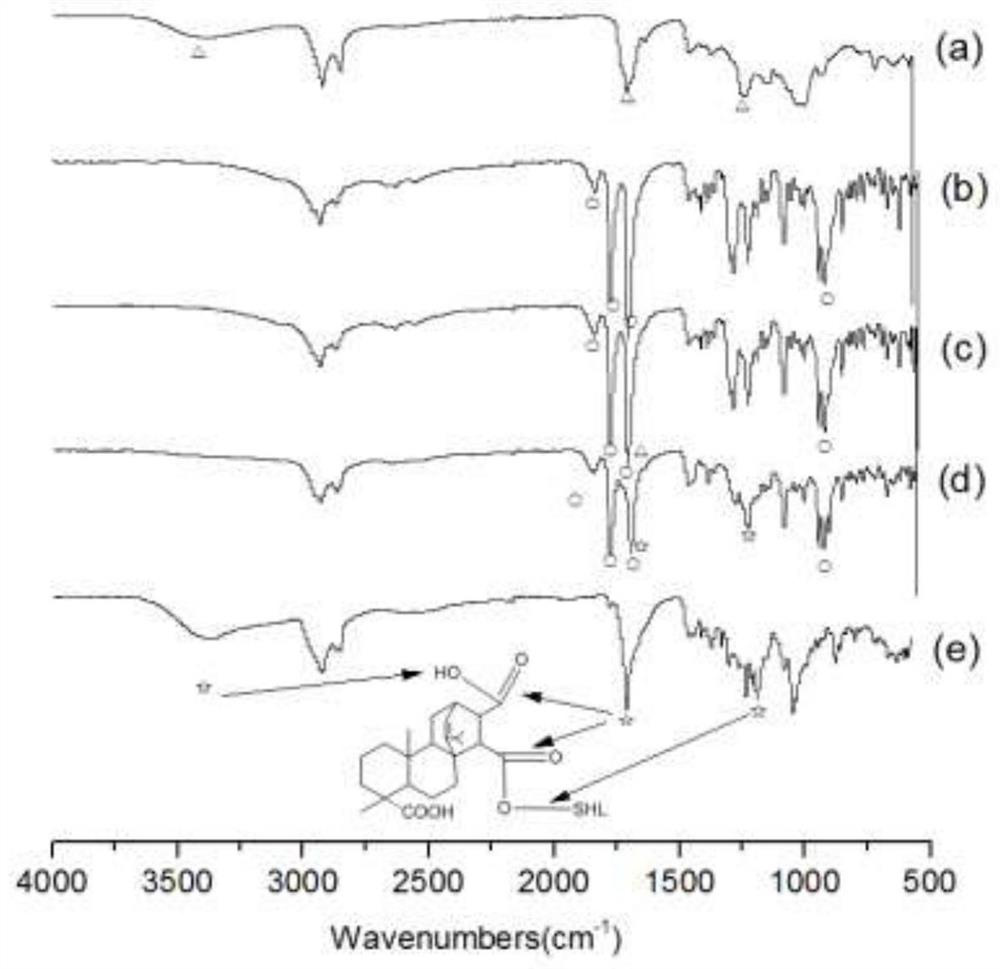

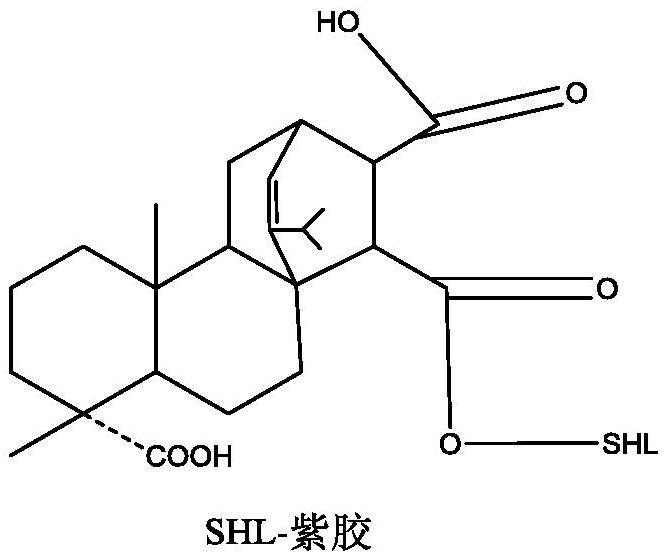

[0041] The second step, mechanical grinding: Weigh 40g (b) of maleic rosin, 25g (a) of shellac, and 0.04g of ZnO, mix them evenly, put them into a grinding jar, add grinding balls of the same quality as the materials; put the grinding jar into Ball mill, grind at normal temperature for 160 minutes, the ball mill rotating speed is 250 rev / min; product and grinding ball are separated, sampling (c).

[0042] The third step, annealing reaction: put the ground material in a constant temperature blast drying oven, react at 80°C for 12h, and cool to room temperature with the furnace after the reaction, and take a sample (d).

[0043] In the fourth step, wash with absolute ethanol 10 t...

Embodiment 2

[0045] A method for preparing rosin-lac esters by solid phase reaction, comprising the steps of:

[0046] The first step, the preparation of rosin adduct: Weigh 100g of rosin, raise the temperature to 170°C, stir, slowly add 30g of maleic anhydride, and react at 195°C for 3h to obtain maleated rosin.

[0047] The second step, mechanical grinding: weigh 40g of maleic rosin, 25g of shellac, and 0.04g of ZnO, mix them evenly, put them into a grinding tank, add grinding balls of the same quality as the materials; put the grinding tank into a ball mill, and grind at room temperature 160 minutes, the speed of the ball mill is 250 rpm; separate the product from the grinding balls. The third step, annealing reaction: put the ground material in a constant temperature blast drying oven, react at 80°C for 24h, and cool to room temperature with the furnace after the reaction.

[0048] In the fourth step, wash with absolute ethanol 10 times that of the product at room temperature, vacuum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com