Foamed aluminum prefabricated plate and connecting method thereof

A technology of prefabricated panels and foamed aluminum, applied in the field of foamed aluminum components, can solve problems such as poor sealing, inability to effectively block sound, light, electromagnetic waves, and unstable installation and fixation, and achieve simple structure, improved electromagnetic properties, Good sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

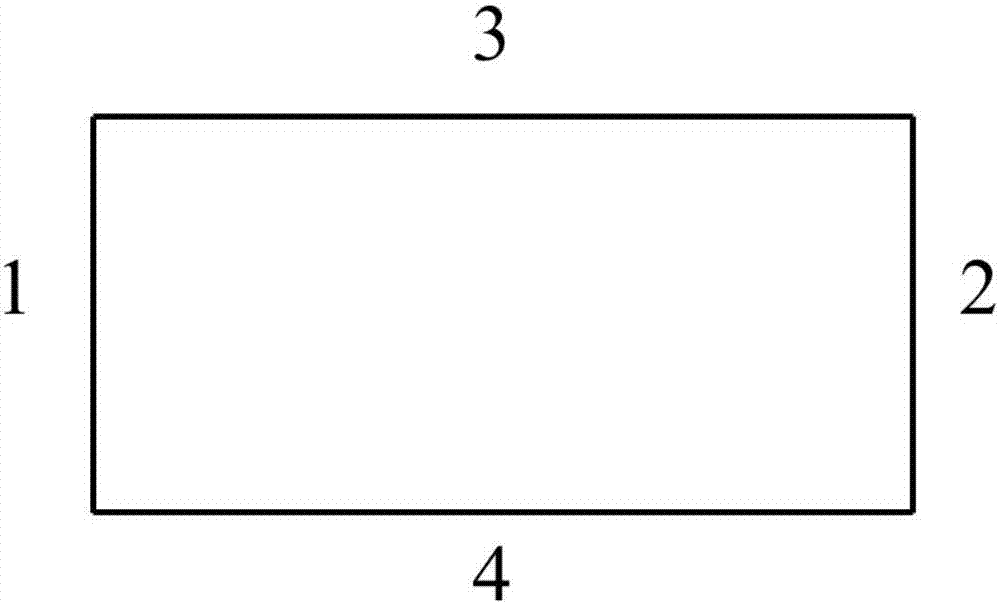

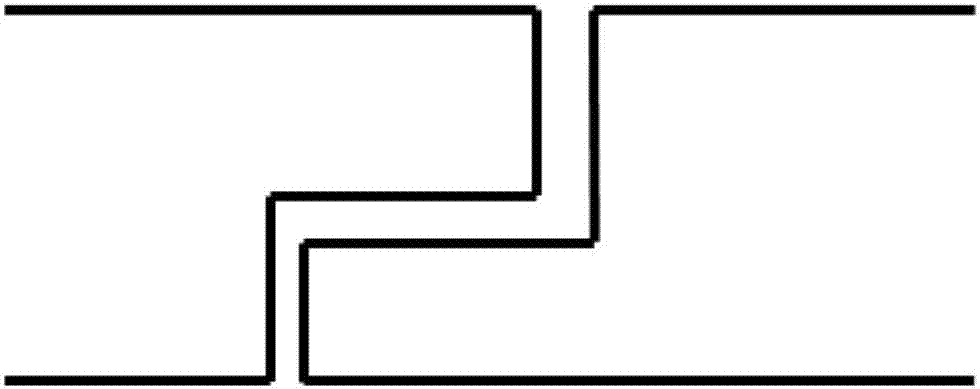

[0019] like figure 1 , figure 2 Shown, a kind of foamed aluminum prefabricated board comprises a foamed aluminum prefabricated board, and the peripheral edge of the foamed aluminum prefabricated board is designed into a geometric structure along the thickness direction, and fits in a geometric form, and the opposite side of the prefabricated board (1 and 2, 3 and 4 ) is the opposite of the geometric matching form; when the foamed aluminum prefabricated panels are used in a geometric form, the connection method can be connected by one of rivet connection, welding connection, bolt connection or gluing, or two or more matching methods. The geometric matching structure can be L-shaped.

[0020] Foamed aluminum prefabricated panels are made of the following 100% by mass components: TiH 2 1%, Ca 2.5%, iron oxide 5%, copper oxide 3%, nickel oxide 2%, silicon oxide 1%, magnesium oxide 1%, and the balance is aluminum.

[0021] The porosity of the foamed aluminum is controlled by th...

Embodiment 2

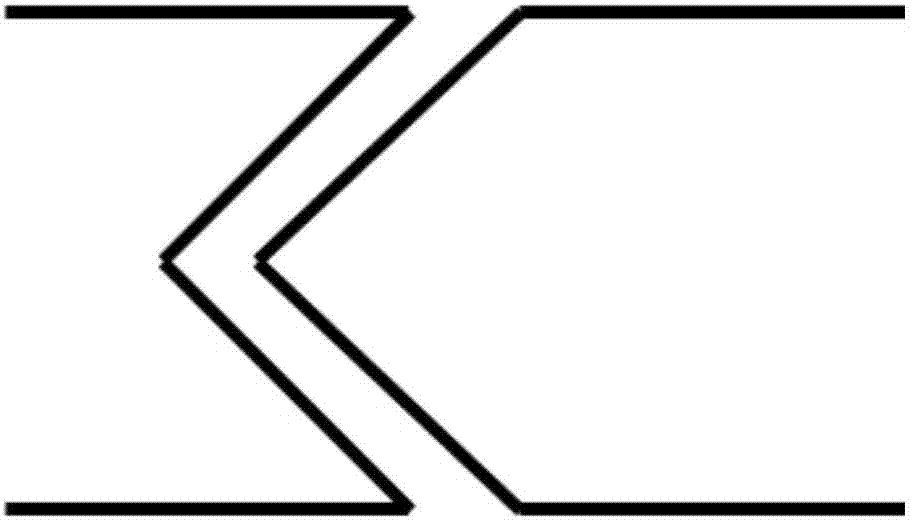

[0023] like figure 1 , image 3 Shown, a kind of foamed aluminum prefabricated board comprises a foamed aluminum prefabricated board, and the peripheral edge of the foamed aluminum prefabricated board is designed into a geometric structure along the thickness direction, and fits in a geometric form, and the opposite side of the prefabricated board (1 and 2, 3 and 4 ) is the opposite of the geometric matching form; when the foamed aluminum prefabricated panels are used in a geometric form, the connection method can be connected by one of rivet connection, welding connection, bolt connection or gluing, or two or more matching methods. The geometric matching structure can adopt V shape.

[0024] Foamed aluminum prefabricated panels are made of the following 100% by mass components: TiH 2 1%, Ca 2.5%, iron oxide 5%, copper oxide 3%, nickel oxide 2%, silicon oxide 1%, magnesium oxide 1%, and the balance is aluminum.

[0025] The porosity of the foamed aluminum is controlled by t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com