Laminated molybdenum disulfide field effect transistor, preparation method and application thereof

A technology of field effect transistors and molybdenum disulfide, applied in transistors, measuring devices, instruments, etc., can solve problems such as difficult to meet low voltage, complicated operation, easy to change device interface structure, etc., and achieve the effect of low turn-on voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

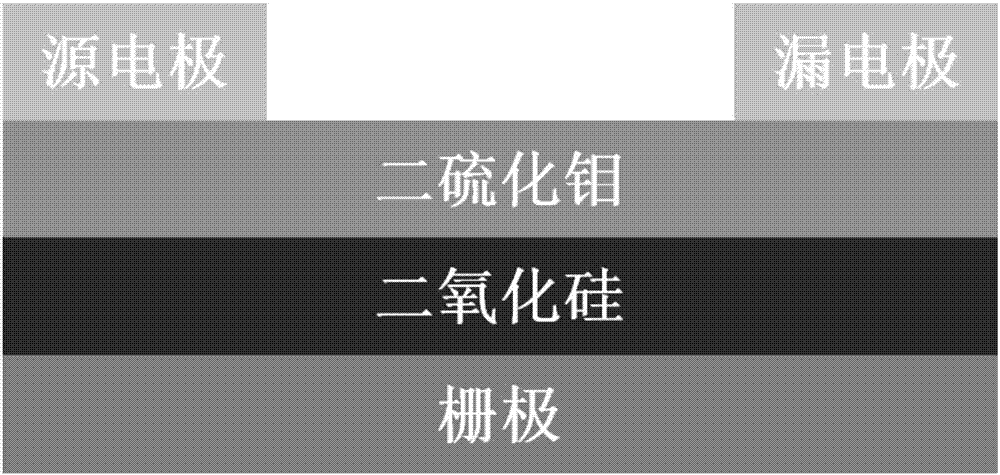

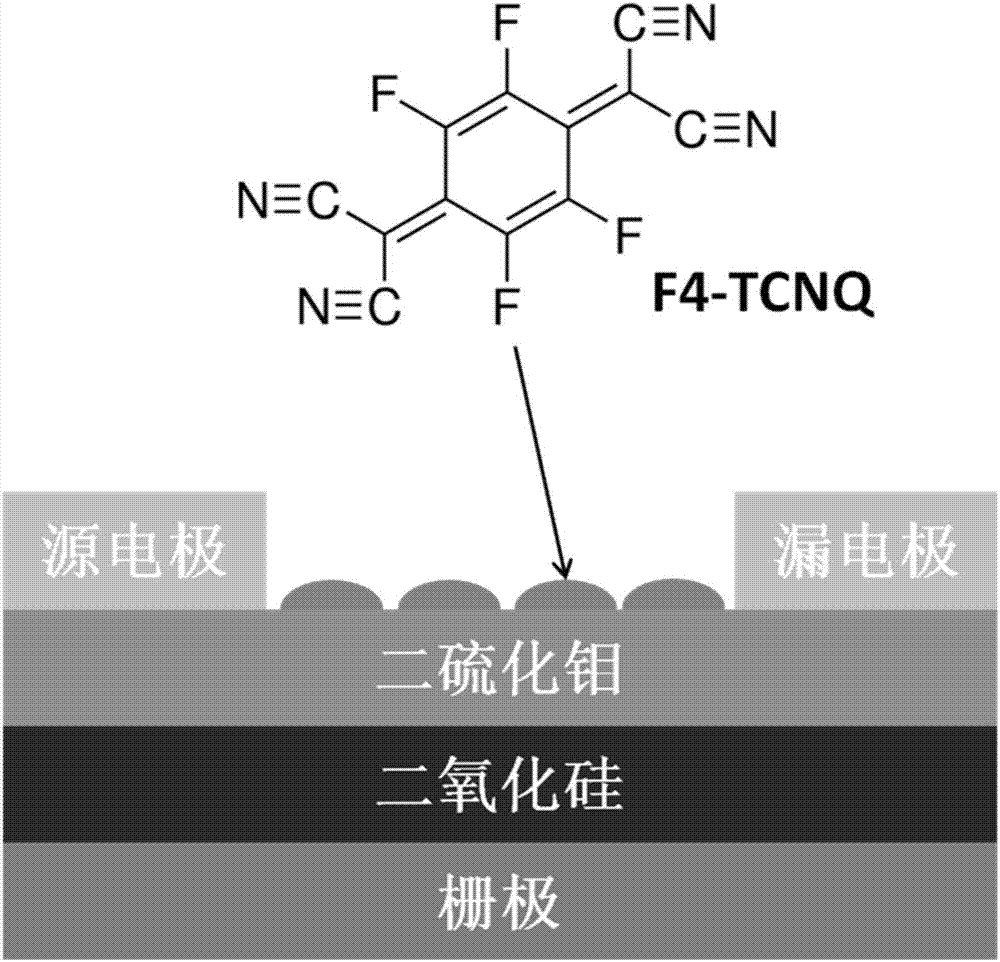

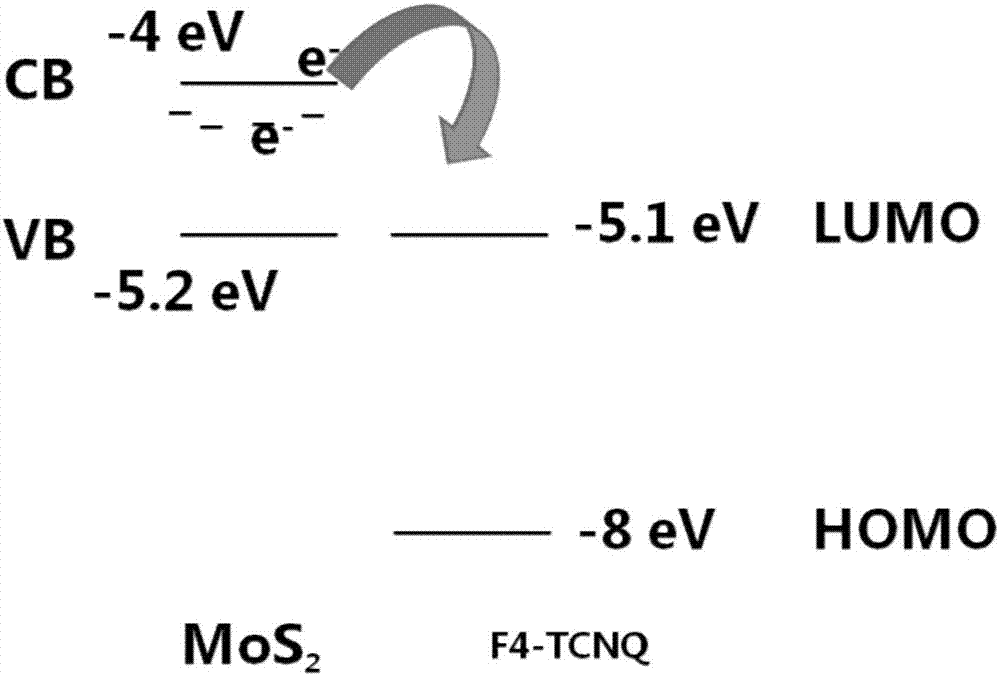

[0044] on SiO by mechanical exfoliation 2 / Si substrate to obtain MoS 2 , using electron beam exposure to prepare electrode patterns. at 3×10 -5 Vacuum deposition of 40nm / 8nm Au / Cr at a speed of 0.01nm / s in the case of Pa to obtain MoS 2 field effect transistor. Then in MoS 2 FETs, at 3 x 10 -5 Vacuum deposition of 10nm F4-TCNQ at a speed of 0.1nm / s under Pa vacuum, such as figure 2 shown. Devices were measured in a vacuum probe station, and the transfer curves were as Figure 4 shown. It can be seen that the undoped MoS 2 The turn-on voltage of the field effect transistor is -60V, and the turn-on voltage after doping F4-TCNQ is greatly reduced, about -5V. And doping F4-TCNQ reduces the sub-threshold swing of the device from 2.14V / decade to 0.91V / decade, and improves the turn-on speed of the device.

Embodiment 2

[0046] Further carried out NH 3 For the measurement of the sensor, a certain amount of NH is introduced into the vacuum chamber of the probe station 3 , to measure the sensitivity of the sensor as Figure 5 shown. It can be seen that the MoS prepared by this scheme 2 Field effect transistors can be used as NH with low gate voltage (-5V) 3 sensor, its 1000ppm sensitivity reaches about 670000%, which is much higher than the 60% sensitivity reported in the prior art (such as Late, D.J. et al.Sensing Behavior of Atomically Thin-Layered MoS 2 Transistors.ACS Nano, Volume 7, Issue 6, Pages 4879-4891), proves that the present invention has the potential application value of preparing excellent sensors.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com