Electrolyte for lithium secondary battery and lithium-oxygen secondary battery

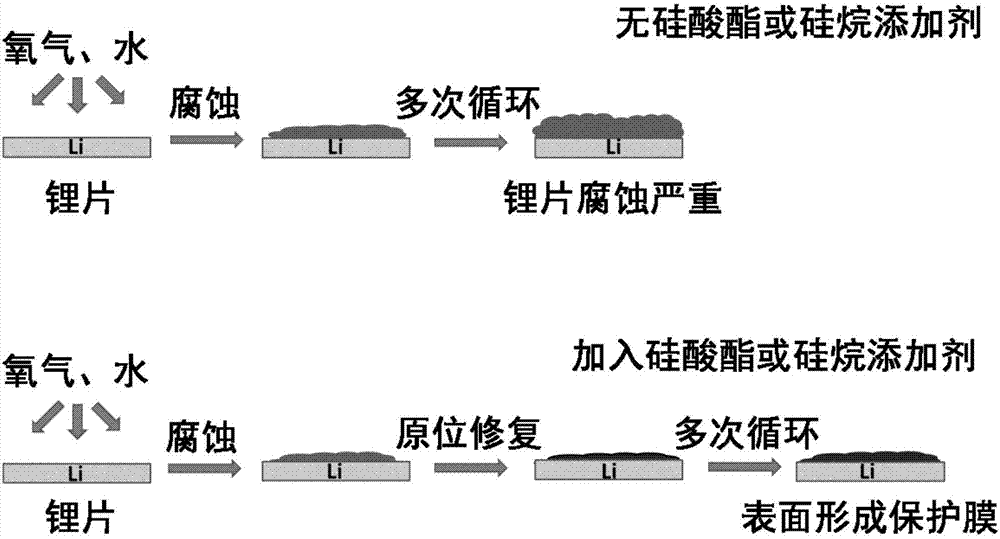

A lithium secondary battery, secondary battery technology, applied in secondary batteries, fuel cell type half cells, secondary battery type half cells, battery electrodes, etc., can solve the complex reaction process conditions and consume large energy raw materials and other problems, to achieve the effects of corrosion mitigation, voltage stabilization, corrosion mitigation and even exhaustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

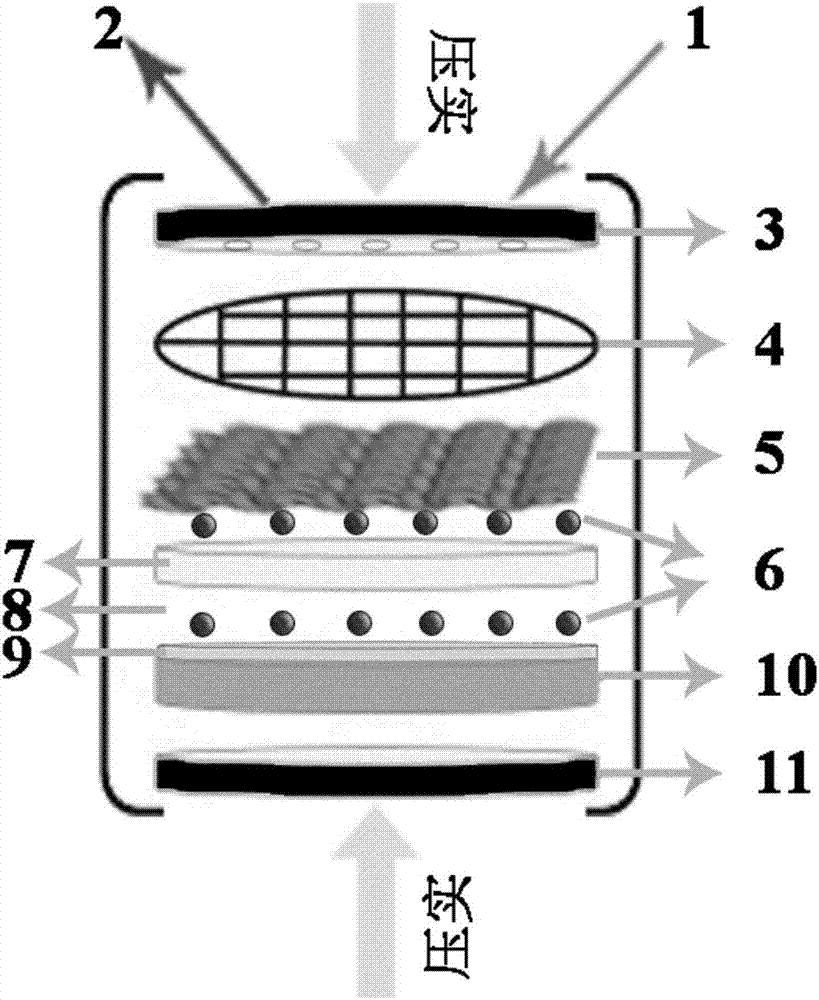

[0094] This embodiment provides a lithium-oxygen secondary battery based on a highly reversible lithium negative electrode (high cycle life lithium negative electrode), and its structure can be referred to figure 1 As shown, the cathode gas (ie working gas) used in this embodiment is oxygen, and the battery number of this embodiment is marked as A1.

[0095] The negative electrode of the present embodiment is lithium metal;

[0096] Lithium flakes can be made by:

[0097] In an argon-protected glove box, the dried lithium plates were rolled into flakes with a thickness of 0.4 mm.

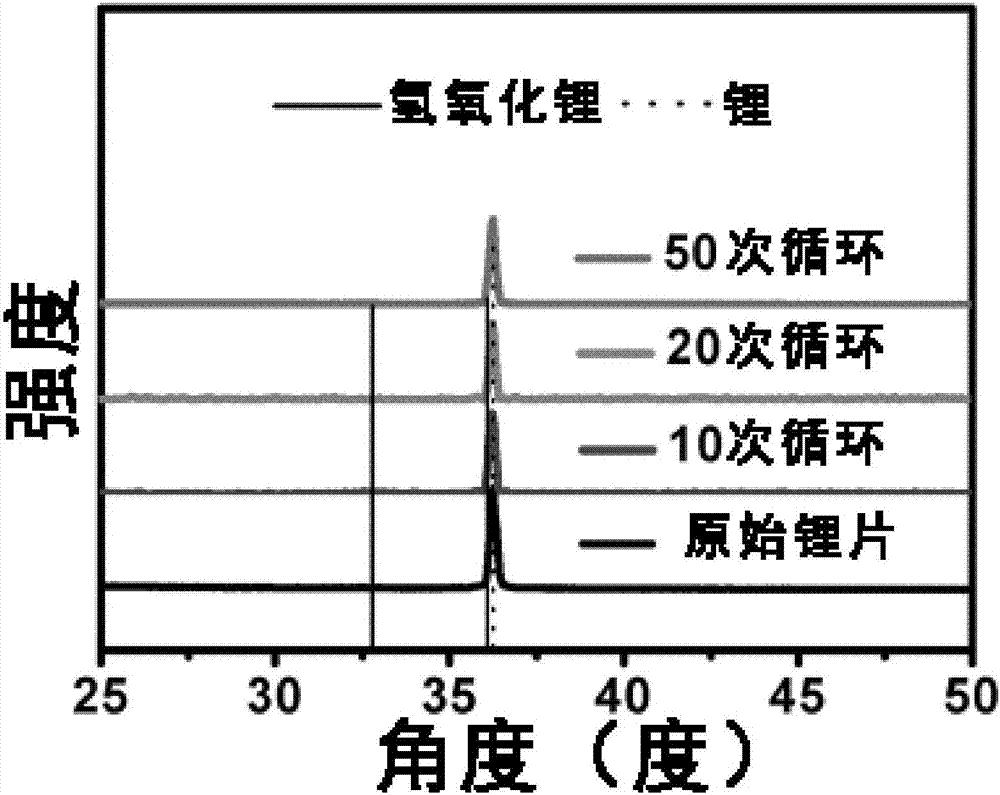

[0098] The metal lithium prepared in the above steps of the present invention is detected. see image 3 , image 3 The X-ray diffraction patterns of the initial state of the lithium negative electrode prepared in Example 1 of the present invention, after 10 cycles, after 20 cycles and after 50 cycles.

[0099] The positive electrode in this embodiment is composed of conductive carbon black and ...

Embodiment 2

[0117] This embodiment provides a lithium-oxygen secondary battery based on a highly reversible lithium negative electrode (high cycle life lithium negative electrode), denoted as A2, and its structure is basically the same as that of the battery provided in Example 1. The amount of silicate / silane added was varied in this example.

[0118] In this embodiment, the amount of silicate / silane added accounts for 1 wt% of the electrolyte.

[0119] The morphology of the lithium negative electrode of the lithium-oxygen battery assembled in the above steps of the present invention is analyzed.

[0120] see Figure 8 , Figure 8 Scanning electron microscope pictures of the lithium negative electrode of the lithium-oxygen secondary battery prepared in Example 2 of the present invention after 10 cycles. Depend on Figure 8 It can be seen that after 10 cycles, the surface of metal lithium is uneven, indicating that the surface is corroded seriously.

[0121] The electrochemical test ...

Embodiment 3

[0124] This embodiment provides a lithium-oxygen secondary battery based on a highly reversible lithium negative electrode (high cycle life lithium negative electrode), denoted as A3, and its structure is basically the same as that of the battery provided in Example 1. The amount of silicate / silane added was varied in this example.

[0125] In this embodiment, the addition amount of silicate / silane accounts for 10 wt% of the electrolyte solution.

[0126] The morphology of the lithium negative electrode of the lithium-oxygen battery assembled in the above steps of the present invention is analyzed.

[0127] see Figure 10 , Figure 10 Scanning electron microscope pictures of the lithium negative electrode of the lithium-oxygen secondary battery prepared in Example 3 of the present invention after 10 cycles. Depend on Figure 10 It can be seen that after 10 cycles, there is no obvious corrosion on the surface, indicating that the protection performance is good.

[0128] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com