Preparation method of colloid quantum-dot microdisc by water drop method

A technology of colloidal quantum dots and microdisks, which is applied in the field of colloidal quantum dots and microdisk lasers, can solve the problems of complex fabrication methods and failure to integrate nanophotonics devices, and achieve the effects of flat surface, uniform interior and narrow line width.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further elaborated below through specific embodiments in conjunction with the accompanying drawings.

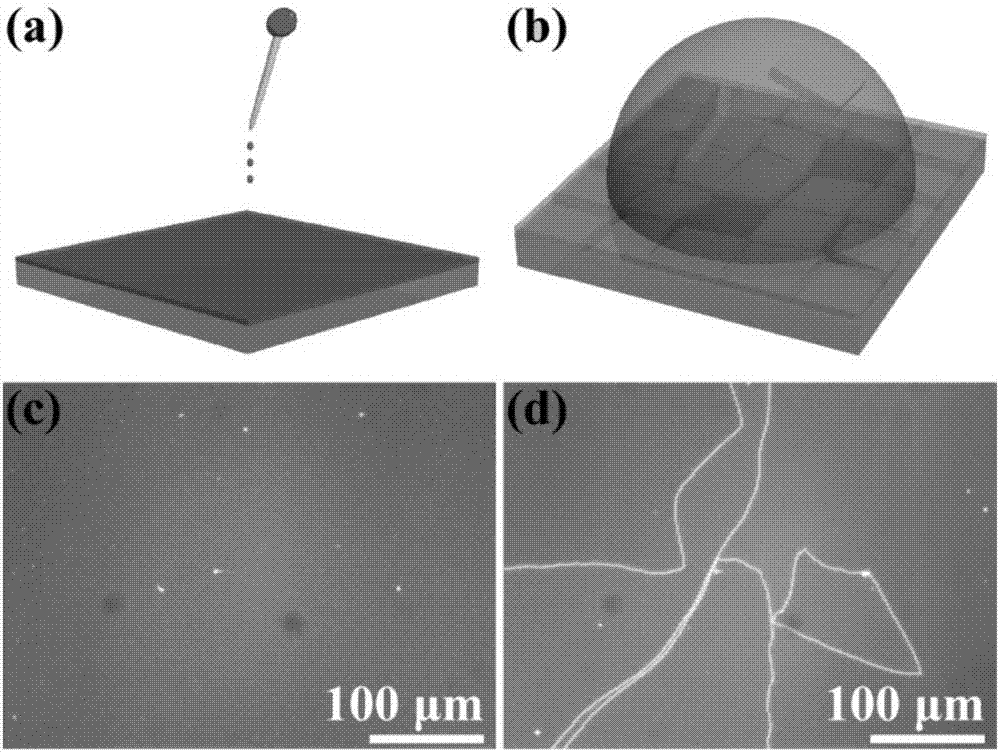

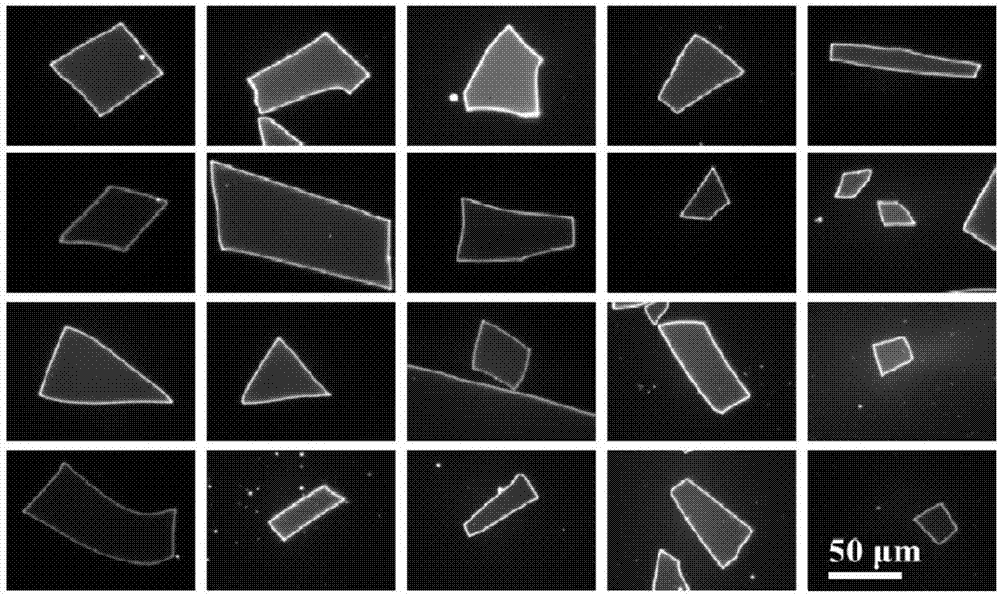

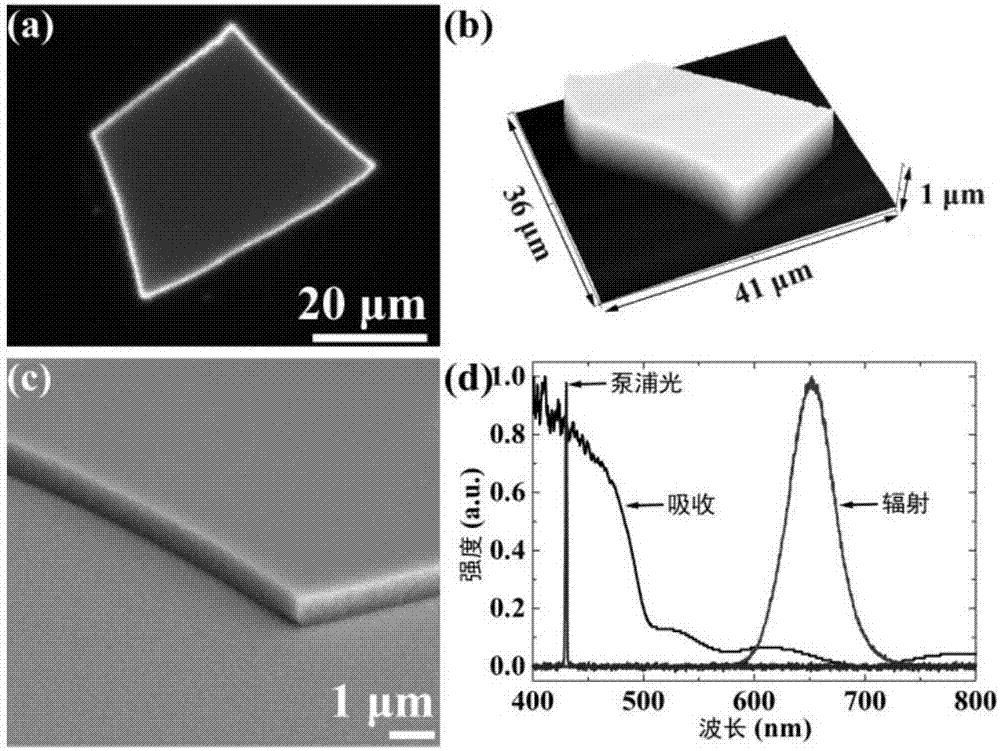

[0033] Such as figure 1 As shown, the preparation method of the colloidal quantum dot microdisk by the water drop method of the present embodiment comprises the following steps:

[0034] 1) CdSe / ZnS core / shell quantum dots are dissolved in hexane. The CdSe core diameter and ZnS shell thickness of the quantum dots are 6.7±0.2nm and 1.5±0.3nm respectively, and the surface ligand is oleic acid. The quantum dots in the solution The efficiency is close to 62%. Octane is added to the hexane quantum dot solution to form a mixed solvent colloidal quantum dot solution, and the volume ratio of hexane to octane is 5:1;

[0035] 2) Provide a glass substrate with a clean surface: ultrasonic cleaning in toluene, acetone and alcohol for 7 minutes;

[0036] 3) Control the ambient temperature at 25°C, and drop-coat the mixed solvent colloidal proton dot...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com