Process for producing iodine from copper containing oxidases useful as iodine oxidases

A technology of copper oxidase and iodide, which is applied in the direction of oxidoreductase, biochemical equipment and methods, and microbial measurement/inspection, and can solve complex, expensive, dangerous and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment I. Materials and methods

[0018] A. raw material

[0019]Chemicals used as buffers and substrates were at least reagent grade commercial products. Ascorbate oxidase (squash species), ceruloplasmin (porcine plasma), bilirubin oxidase (Myrocorroderma verruca) and tyrosinase (mushroom) were purchased from Sigma and used as received. Enzyme content in lyophilized powders or solutions was confirmed using UV-vis absorption and published extinction coefficients. The activity of ascorbate oxidase was confirmed with ascorbic acid.

[0020] B. method

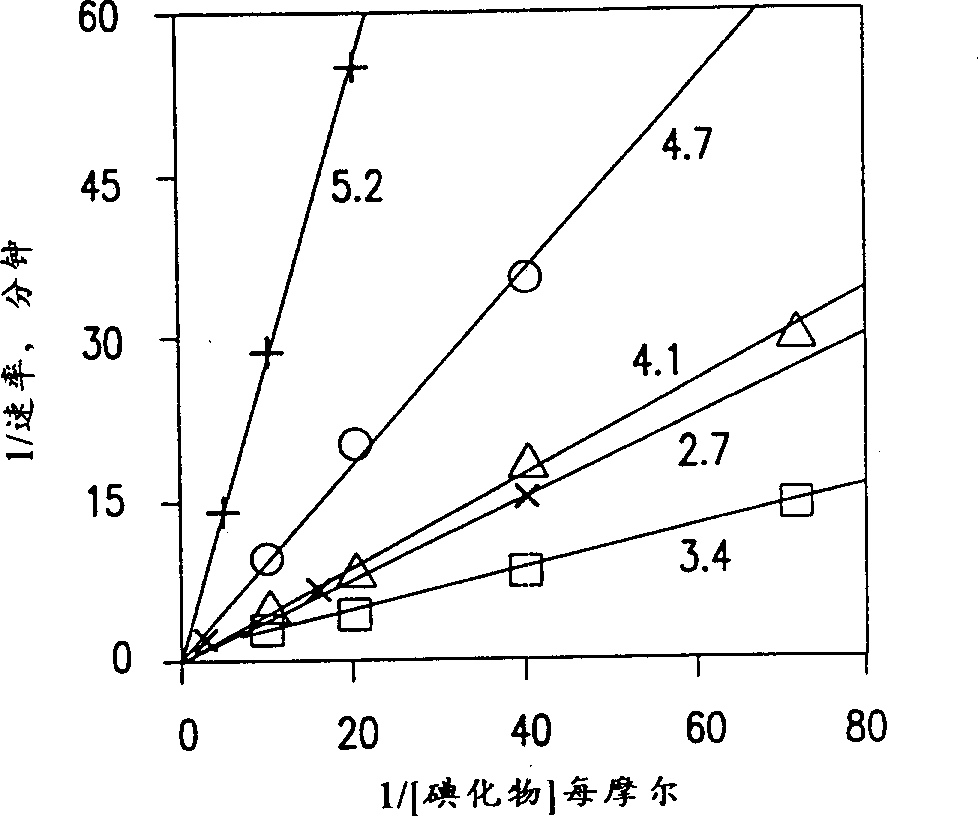

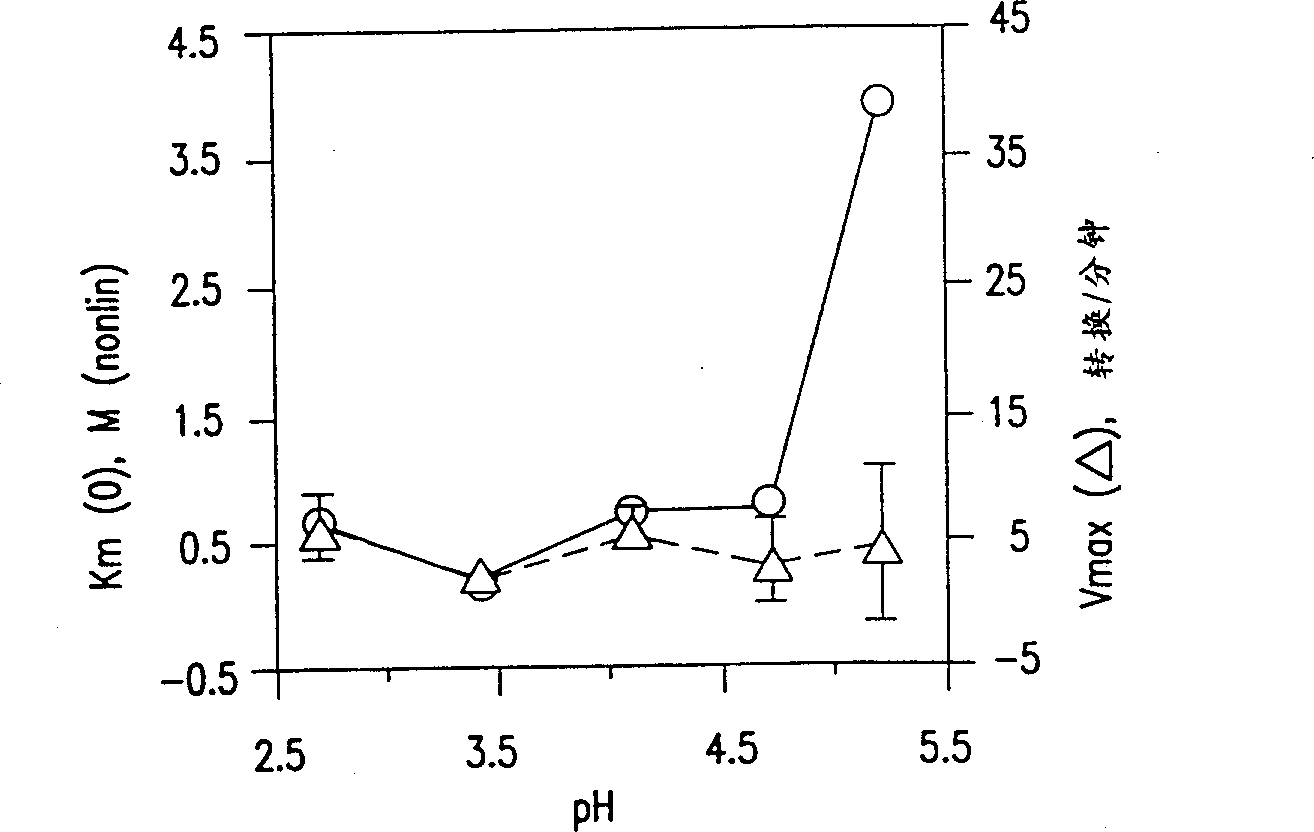

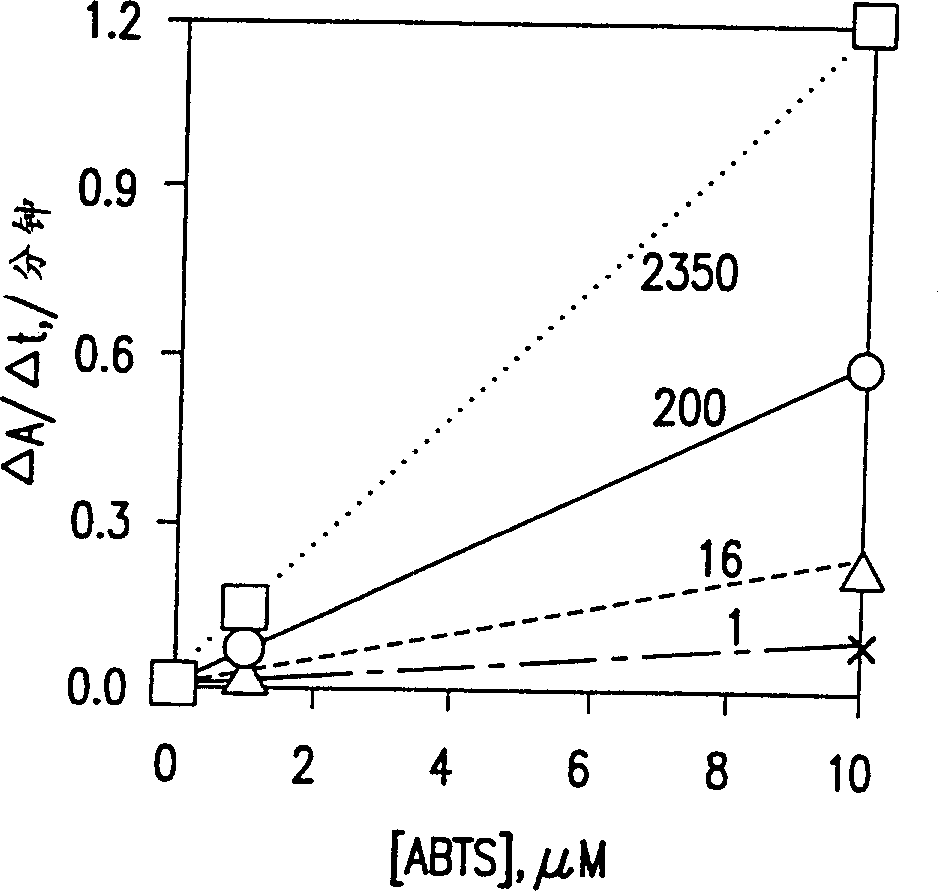

[0021] Recombinantly produced Myceliophthora thermophila laccase (r-MtL; described in co-pending U.S. Serial No. 08,278,473, the contents of which are hereby incorporated by reference) was purified and treated with syringaldazine and 2,2'-Azinobis(3-ethylbenzothiazoline-6-sulfonic acid)·(ABTS) oxidation reaction to determine its activity: syringaldazine oxidation reaction was performed in a 1 cm quartz cuvette c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com