Preparation method of solid-phase micro-extraction fiber with specificity to sulfanilamide medicine

A technology for extracting sulfa drugs and fibers, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., to achieve strong specific adsorption capacity, high recovery rate, and solve the effects of poor selective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The preparation method of solid phase microextraction fiber material is as follows:

[0055] The preparation method of the solid-phase microextraction fiber specific to sulfonamides comprises the following steps:

[0056] (1) Dissolve 556mg of sulfamethazine in 5.5mL of acetonitrile, ultrasonically dissolve it fully, then add 256μL of functional monomer methacrylic acid for 5min, and then add the cross-linking agent ethylene glycol dimethacrylic acid Esters 1.128mL and 1.188mL 3-(trimethoxysilyl)propyl acrylate, ultrasonic 5min to fully mix all reagents, then add 25mg of azobisisobutyronitrile, ultrasonically dissolved to obtain a pre-polymerization solution;

[0057] (2) Ultrasonicate the pre-polymerization solution prepared in step 1) for 2 minutes, pass nitrogen gas for 2 minutes, repeat the operation 5 to 10 times to remove oxygen, and store in a refrigerator at 4°C away from light;

[0058] Solid phase microextraction material preparation, its steps are as follows...

Embodiment 2

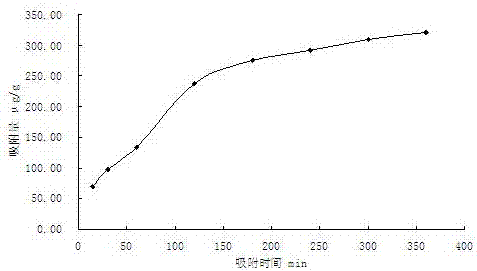

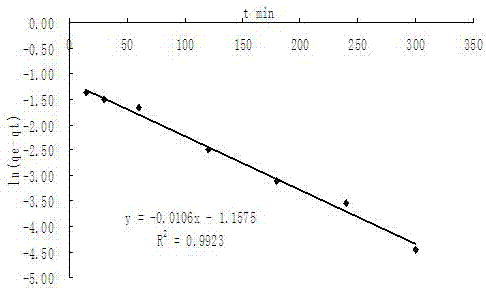

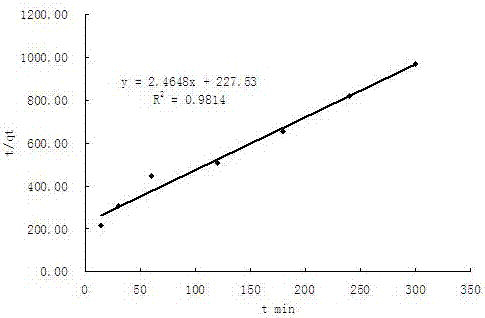

[0066] Characterization of Adsorption Properties of Solid Phase Microextraction Materials

[0067] (1) Dynamic adsorption experiment

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com