Stone slab truss type automatic discharging device and method

An automatic material cutting and stone material technology, which is applied in the direction of transportation and packaging, object stacking, conveyor objects, etc., can solve the problems of low efficiency and achieve the effect of reliable adsorption, accurate positioning, and optimized material cutting action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] Below in conjunction with accord with embodiment and further illustrate along with the present invention.

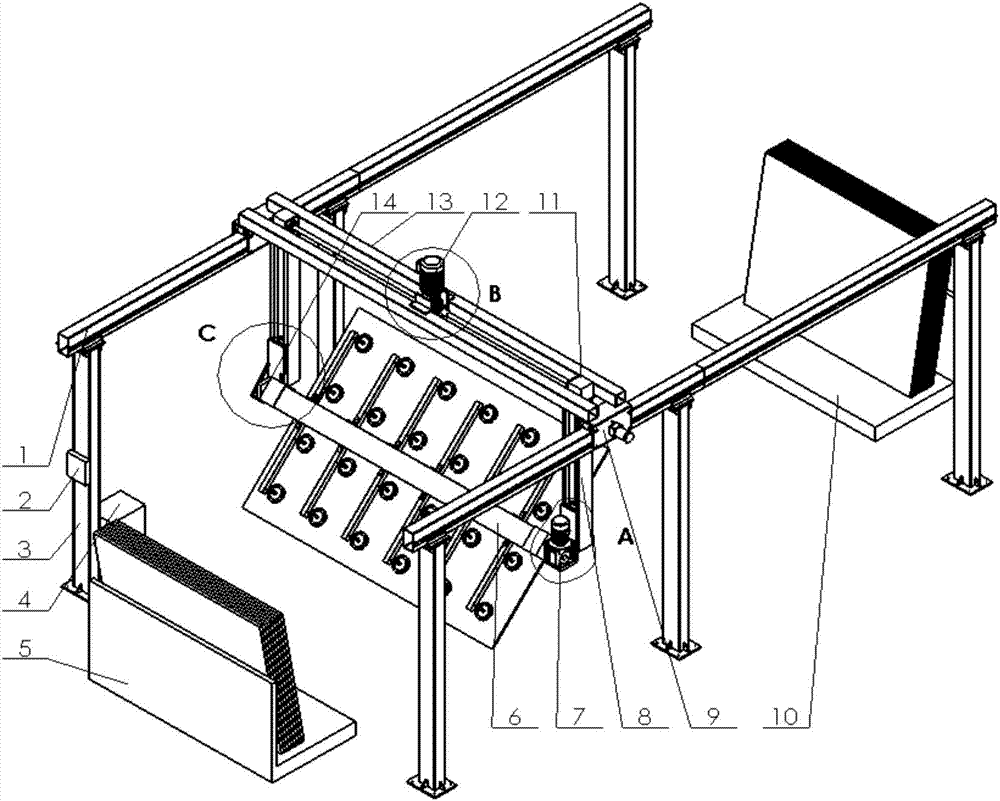

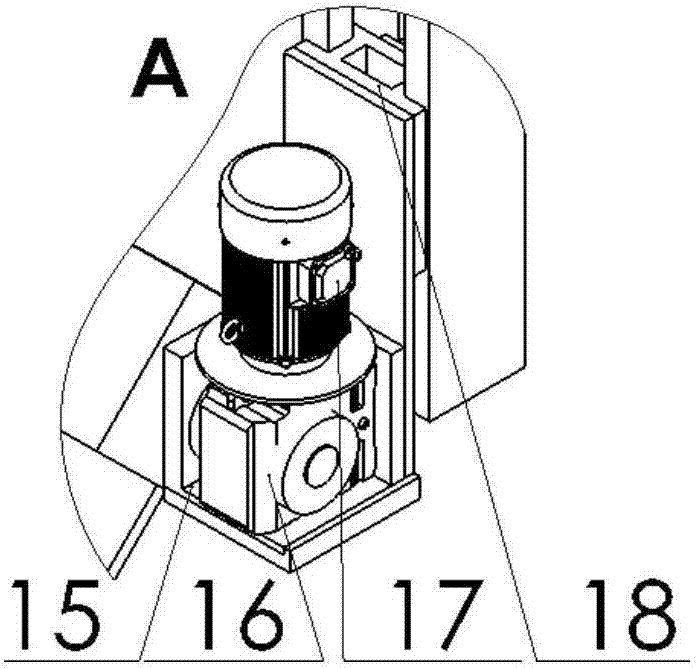

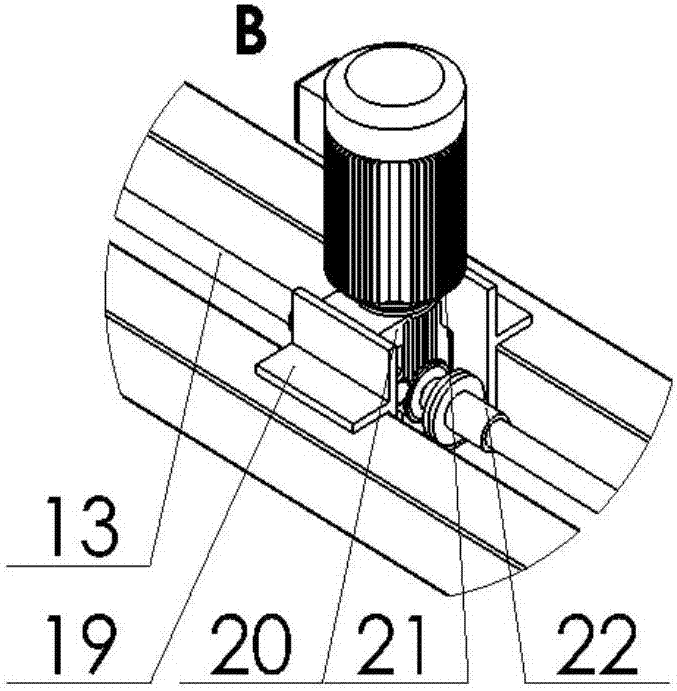

[0043] As attached to the manual Figure 1-4As shown, the stone slab truss-type unloading device includes a frame, a lateral movement mechanism, a vertical movement mechanism, a suction cup assembly, a ferry car, a plate palletizing platform, an electric control cabinet and an operation panel. The invention can absorb stone slabs with a maximum format of 3200mm×2500mm and a thickness of 20mm. The device has a reasonable layout, makes full use of the workshop space, reduces labor intensity, improves production efficiency and reduces production cost. The invention also discloses a loading and unloading method using the automatic loading and unloading device.

[0044] Such as figure 1 , the frame mechanism includes two (or several connected together) parallel transverse beams 1 at a certain distance, the two ends of each transverse beam are supported by two uprigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com