Modified lignite-based adsorption material as well as preparation method and application thereof

An adsorption material, lignite-based technology, applied in chemical instruments and methods, adsorption water/sewage treatment, other chemical processes, etc., can solve the problems of limited adsorption capacity and limited adsorption capacity of adsorbents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] The present invention also provides a preparation method of the modified lignite-based adsorption material described in the above technical solution, comprising the following steps:

[0031] (1) Lignite is mixed with hydrochloric acid to carry out acid leaching to obtain a demineralized coal sample;

[0032] (2) mixing the demineralized coal sample obtained in the step (1) with magnesium salt and deionized water, and impregnating to obtain a precursor;

[0033] (3) Roasting the precursor obtained in the step (2) to obtain a modified lignite-based adsorption material.

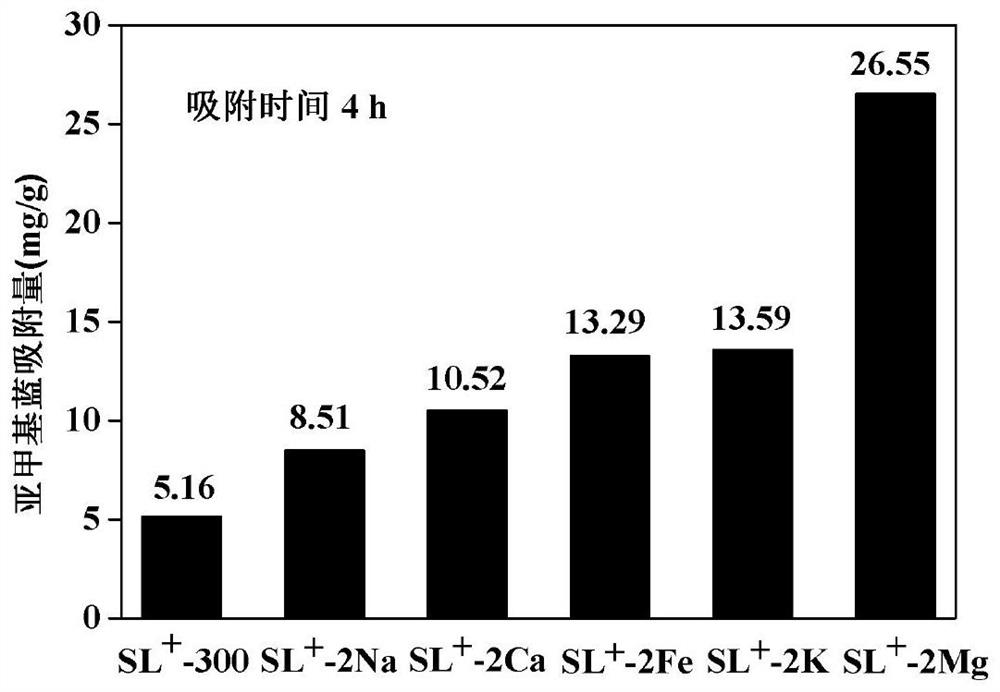

[0034] In the invention, the lignite is mixed with hydrochloric acid for acid leaching to obtain a demineralized coal sample. In the present invention, one or more of inherent metal elements Si, Al, Ca, Mg, Fe, K and Na are included in the lignite, and the acid leaching can remove impurity metal elements in the lignite, so that the acid leaching Only two metal elements, Si and Al, are left in the final ...

Embodiment 1

[0065] (1) Mix 100.0g lignite (hereinafter referred to as SL) with 1000mL 19wt% hydrochloric acid, stir at room temperature for 24h, carry out acid leaching, let stand for 4h, and wash with a large amount of deionized water until the pH of the filtrate is neutral and AgNO 3 No white precipitate formed. The filter cake was dried in a drying oven at 105°C for 6 h, ground and sieved to 200 mesh in a mortar to obtain a demineralized coal sample (SL + ); Wherein, the mass ratio of the volume of hydrochloric acid and SL is 10mL:1.0g.

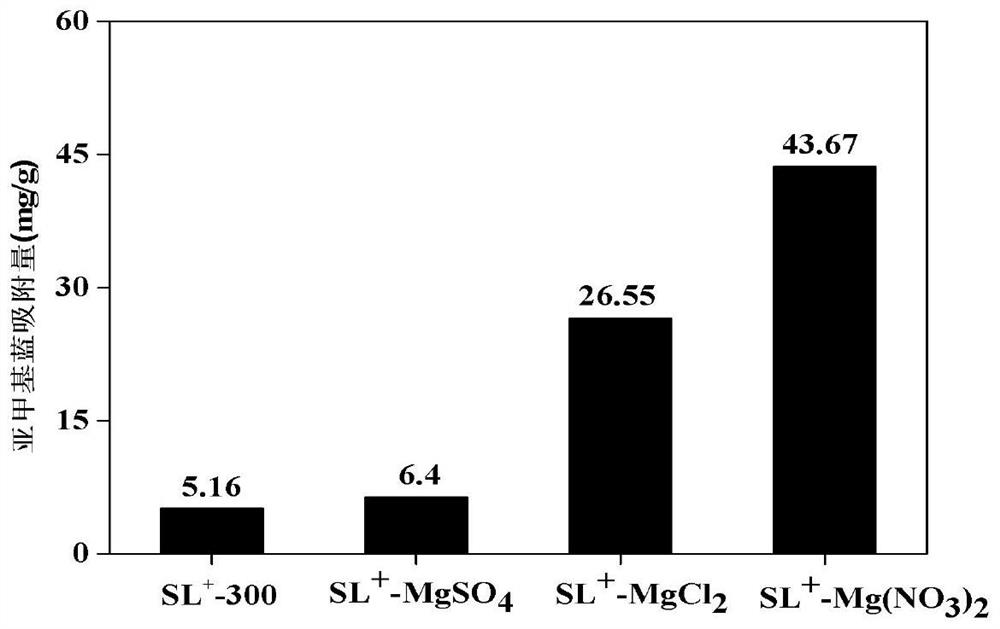

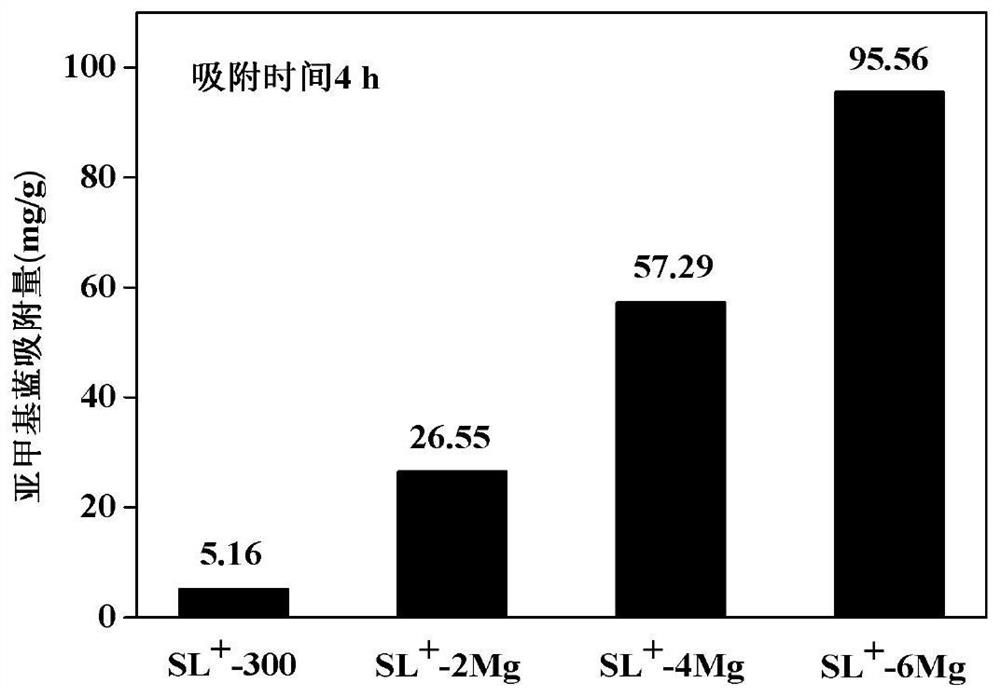

[0066] (2) the 5.0g SL obtained in the step (1) + with MgCl 2 Mix with 75mL deionized water, stir at room temperature for 12h for impregnation, solid-liquid separation after impregnation, and then dry the obtained solid at 105°C to obtain the precursor; MgCl 2 Medium Mg 2+ The quality is SL + 2 wt% of the mass.

[0067] (3) Place the precursor obtained in the step (2) in a tube furnace, heat the sample to 300° C. at a heating rate of 5° C. / min, ...

Embodiment 2

[0088] The difference with Example 1 is that the MgCl in the step (2) 2 Medium Mg 2+ The quality is SL + The 2wt% of mass is changed into 4wt%, all the other steps are identical with embodiment 1, and the adsorbent material that obtains is named after SL + -4Mg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com