Method for preparing composite catalyst for low temperature degradation of dioxin by ball milling

A technology of composite catalyst and ball milling method, which is applied in chemical instruments and methods, catalyst activation/preparation, physical/chemical process catalysts, etc. It can solve the problem of high reaction temperature, poor stability of preparation process, and difficulty in obtaining low-temperature degradation of dioxins with uniform size. Catalyst and other problems, to achieve the effect of lowering the reaction temperature, good low-temperature catalytic reaction activity, and good thermochemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1 2

[0040] The preparation method of embodiment 1 dioxin low-temperature degradation catalyst Cata-1

[0041] Put carbon nanotubes (Jiangsu Xianfeng Nano Material Technology Co., Ltd., model: XFM34, tube diameter > 50nm) in a 1:1 mixture of concentrated sulfuric acid (98%) and concentrated nitric acid (68%) for ultrasonic treatment for 30min, and wash filtering, washing with water until the pH of the filtrate is neutral, and drying to obtain pretreated carbon nanotubes. Mix the precursor according to the ratio of catalyst carbon nanotubes: vanadium pentoxide: titanium dioxide = 5:4:91, the specification of the ball mill tank is 0.5L, and add the corresponding supporting zirconia according to the mass ratio of ball to material ratio of 20:1 Grind the balls for 2 hours under the condition of 400r / min, and then place the powder in a muffle furnace for calcination at 450°C for 4 hours to obtain Cata-1, a low-temperature degradation catalyst for dioxins.

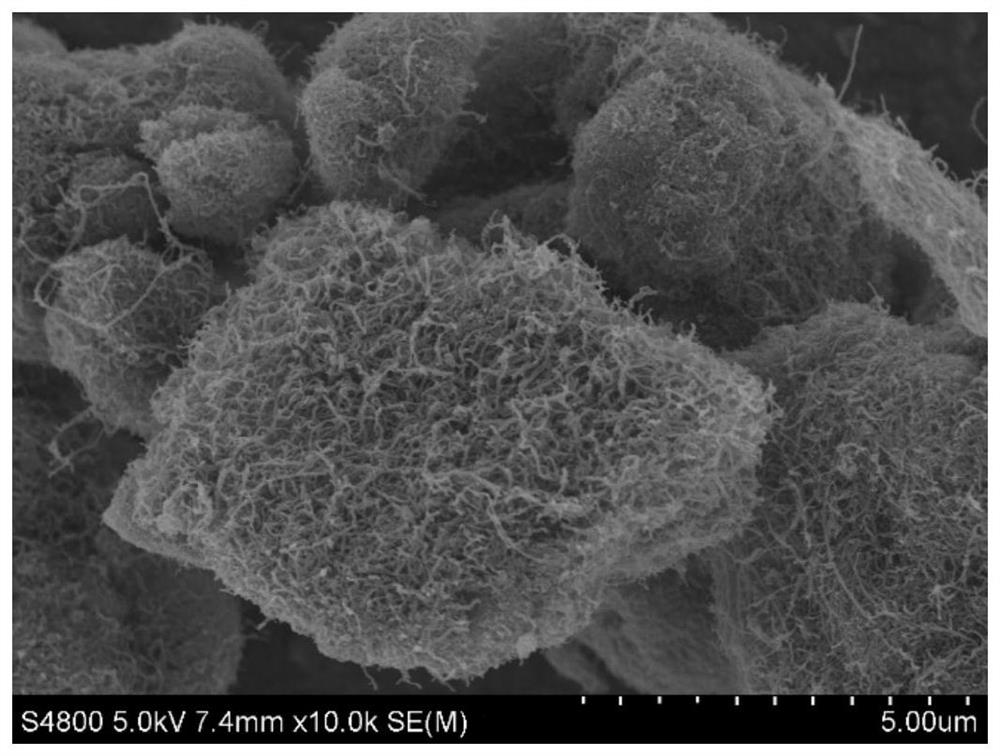

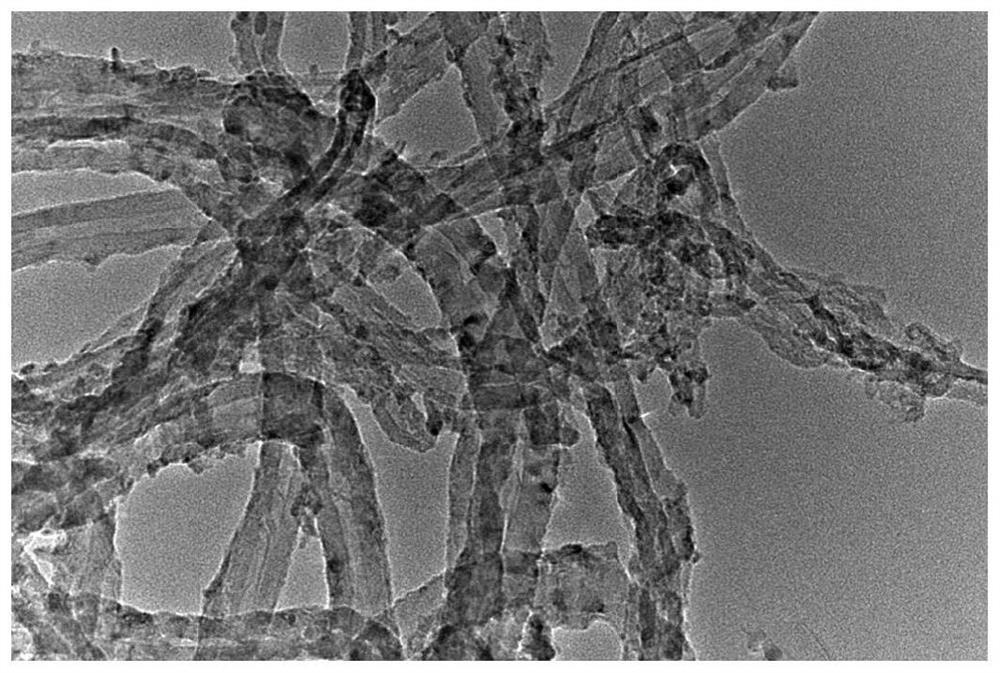

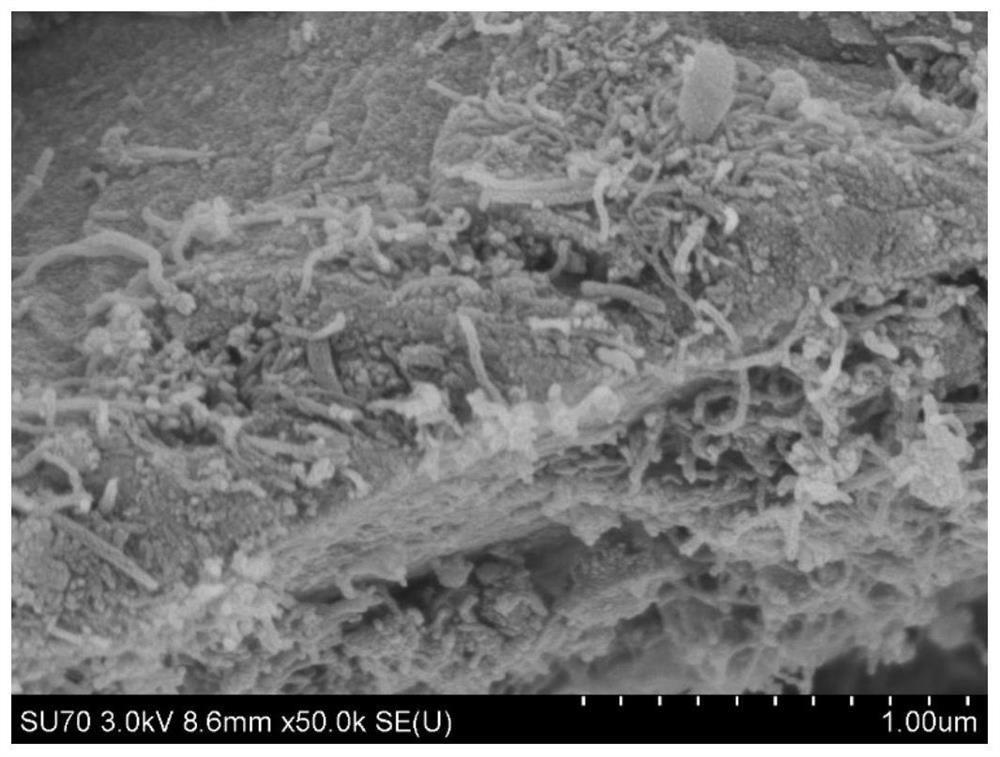

[0042] From figure 1 It can...

Embodiment 2 2

[0043] The preparation method of embodiment 2 dioxin low-temperature degradation catalyst Cata-2

[0044] Carbon nanotubes (Jiangsu Xianfeng Nano Material Technology Co., Ltd., model: XFM34, tube diameter > 50nm) were placed in a 1:1 mixture of concentrated sulfuric acid (98%) and concentrated nitric acid (68%) for ultrasonic treatment for 30 minutes, washing and filtering, washing with water until the pH of the filtrate is neutral, and drying to obtain pretreated carbon nanotubes. Mix the precursor according to the ratio of catalyst carbon nanotubes: vanadium pentoxide: titanium dioxide = 10:4:86, the specification of the ball mill tank is 0.5L, and add the corresponding matching zirconia according to the mass ratio of ball to material ratio of 20:1 Grind the balls for 2 hours under the condition of 400r / min, and then place the powder in a muffle furnace for calcination at 450°C for 4 hours to obtain Cata-2, a low-temperature degradation catalyst for dioxins.

Embodiment 3 2

[0045] The preparation method of embodiment 3 dioxin low-temperature degradation catalyst Cata-3

[0046] Carbon nanotubes (Jiangsu Xianfeng Nano Material Technology Co., Ltd., model: XFM34, tube diameter > 50nm) were placed in a 1:1 mixture of concentrated sulfuric acid (98%) and concentrated nitric acid (68%) for ultrasonic treatment for 30 minutes, washing and filtering, washing with water until the pH of the filtrate is neutral, and drying to obtain pretreated carbon nanotubes. Mix the precursor according to the ratio of catalyst carbon nanotubes: vanadium pentoxide: titanium dioxide: tungsten trioxide = 10:4:72:14, the specification of the ball mill tank is 0.5L, and add according to the mass ratio of ball to material ratio of 20:1 The matching zirconia balls were ground for 2 hours under the condition of 400r / min, and then the powder was calcined in a muffle furnace at 450°C for 4 hours to obtain Cata-3, a low-temperature degradation catalyst for dioxins.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com