Manganese dioxide@poly(m-phenylenediamine)@ferroferric oxide composite material as well as preparation method and application thereof

A technology of ferric oxide and poly-m-phenylenediamine, which is applied in the direction of alkali metal oxides/hydroxides, chemical instruments and methods, alkali metal compounds, etc., and can solve the problem of adsorption capacity, poor adsorption effect, and inter-polymerization Solve the problems of low synthesis temperature of phenylenediamine, achieve strong affinity and good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0061] The preparation method of the 2nd group embodiment, composite material of the present invention

[0062] This group of embodiments provides the preparation method of the manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material described in any one of the first group of embodiments, which is characterized in that it includes the following steps:

[0063] S1, ultrasonically dispersing ferric oxide into water to obtain a ferric oxide dispersion;

[0064] S2, mixing the m-phenylenediamine and the ferric oxide dispersion liquid, and ultrasonically dispersing to obtain the dispersion liquid of ferric oxide and m-phenylenediamine;

[0065] S3, mixing the dispersion of ferric ferric oxide and m-phenylenediamine obtained in step S2 with an oxidant to carry out oxidative polymerization reaction to obtain poly-m-phenylenediamine@ferric oxide composite material;

[0066] S4. Disperse the poly-m-phenylenediamine@ferroferric oxide composite material obtained in step S...

Embodiment 1

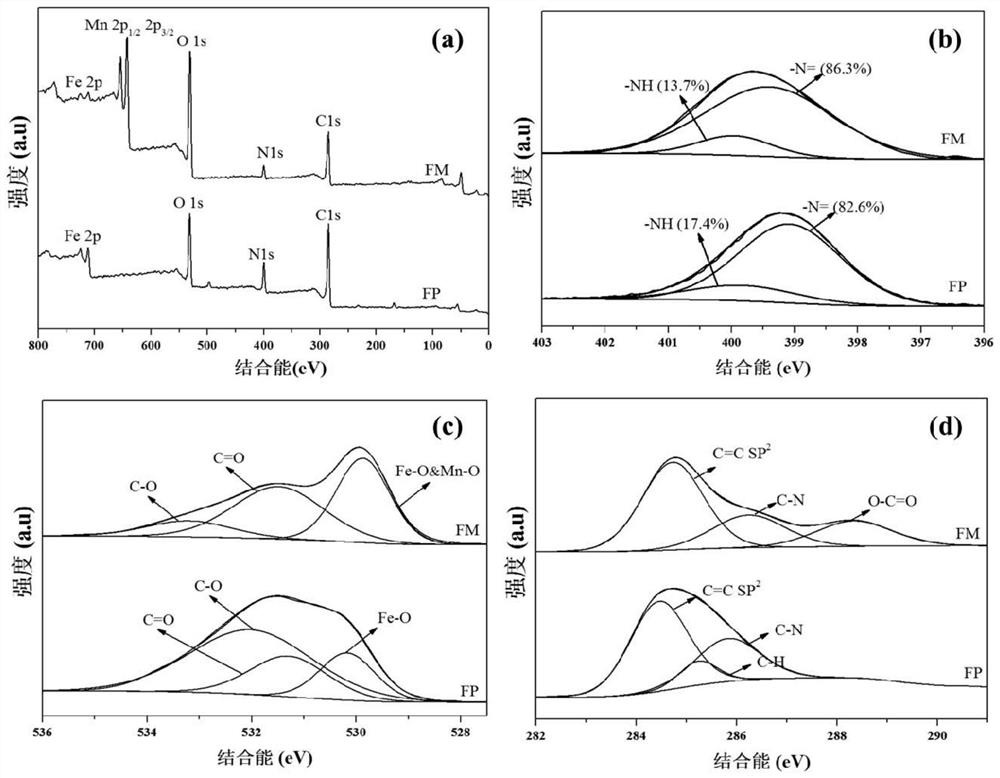

[0077] A manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material, including ferric oxide, manganese dioxide and poly-m-phenylenediamine, wherein poly-m-phenylenediamine is loaded on the surface of ferric oxide, and the two Manganese oxide is supported on the surface of poly-m-phenylenediamine, and is chemically combined with poly-m-phenylenediamine.

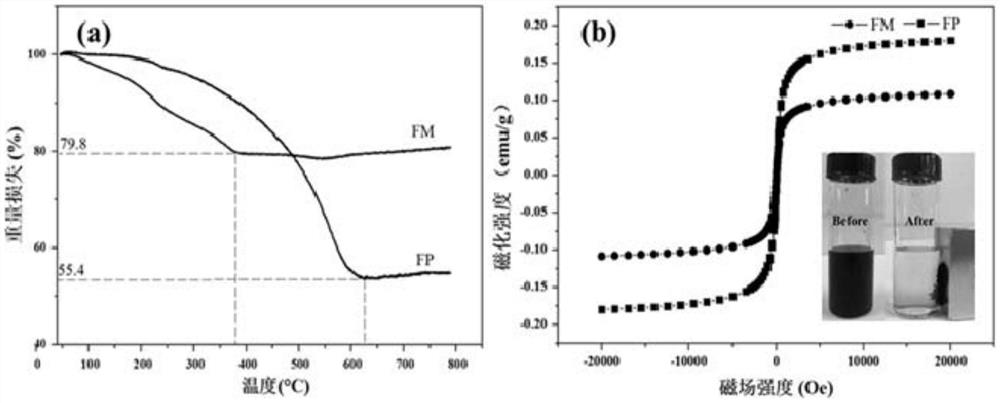

[0078] In this example, the load of poly-m-phenylenediamine is 44.6% of the mass of manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material, and the load of manganese dioxide is manganese dioxide@poly-m-phenylene 24.4% of the mass of the amine@Fe3O4 composite.

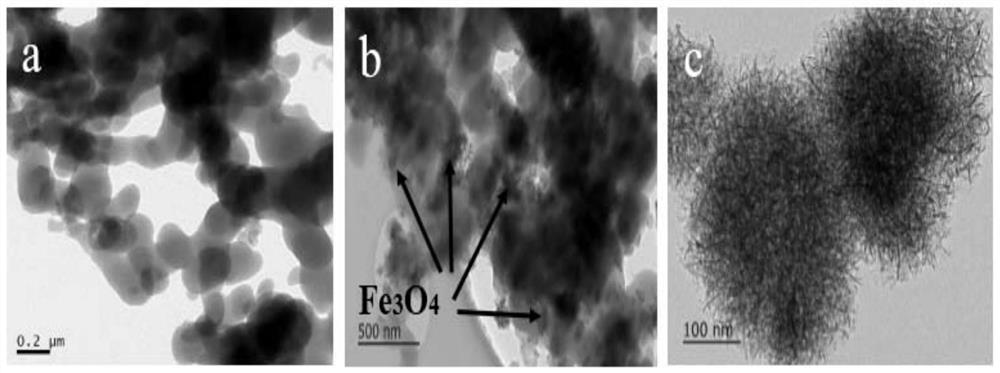

[0079] In this embodiment, ferroferric oxide is spherical with rough surface; poly-m-phenylenediamine is spherical with smooth surface; the manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material is sea urchin-shaped with rough surface .

[0080] In this example, the composite material of manganese dioxide@poly-m-phe...

Embodiment 2

[0106] 1. The application of a manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material in the treatment of heavy metal wastewater, including the following steps:

[0107] Get the ferroferric oxide, manganese dioxide used in comparative example 1, the poly-m-phenylenediamine@ferric oxide composite material obtained in comparative example 1, the poly-m-phenylenediamine obtained in comparative example 2, Manganese dioxide@poly-m-phenylenediamine@ferric oxide composite material (FM50, FM100, FM150, FM200) with manganese dioxide loads of different specific gravity in Example 1 each 5mg in two parts, respectively added to 20mL, In the heavy metal wastewater with a Pb concentration of 100mg / L, a Cd concentration of 50mg / L, and a pH of 5.3, place it in a constant temperature water bath at 25°C and 170rpm for 24 hours of vibration adsorption to complete the treatment of heavy metal wastewater.

[0108] 2. Get the obtained comparative example FP and comparative example...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com