Manganese dioxide@poly(m-phenylene diamine) composite material as well as preparation method and application thereof

A poly-m-phenylenediamine, manganese dioxide technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the influence of adsorption capacity, poor adsorption effect, permanganic acid The problem of high potassium consumption is to achieve the effect of strong affinity, good adsorption effect and efficient treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the 2nd group embodiment, composite material of the present invention

[0060] This group of embodiments provides the preparation method of the manganese dioxide@poly-m-phenylenediamine composite material described in any one of the first group of embodiments, which is characterized in that it includes the following steps:

[0061] S1, ultrasonically dispersing m-phenylenediamine to obtain a dispersion of m-phenylenediamine;

[0062] S2. Mix the dispersion of m-phenylenediamine obtained in step S1 with an oxidant to carry out oxidation polymerization reaction to obtain a poly-m-phenylenediamine material;

[0063] S3. Disperse the poly-m-phenylenediamine material obtained in step S2 into water to obtain a colloidal dispersion, and add potassium permanganate solution to it for redox reaction to obtain manganese dioxide@poly-m-phenylenediamine shell-core structure composite material .

[0064] In some embodiments, the mass ratio of m-phenylenedi...

Embodiment 1

[0075] A manganese dioxide@poly-m-phenylenediamine composite material, including manganese dioxide and poly-m-phenylenediamine, wherein the manganese dioxide is supported on the surface of the poly-m-phenylenediamine, and is chemically combined with the poly-m-phenylenediamine.

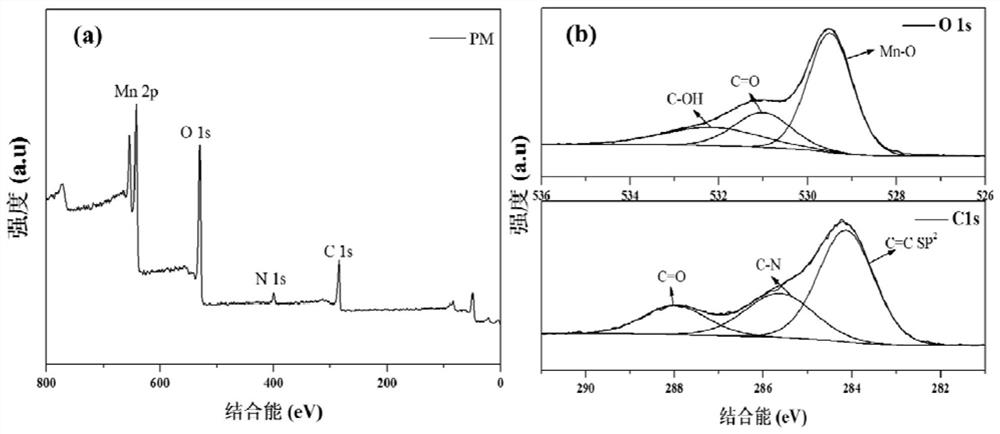

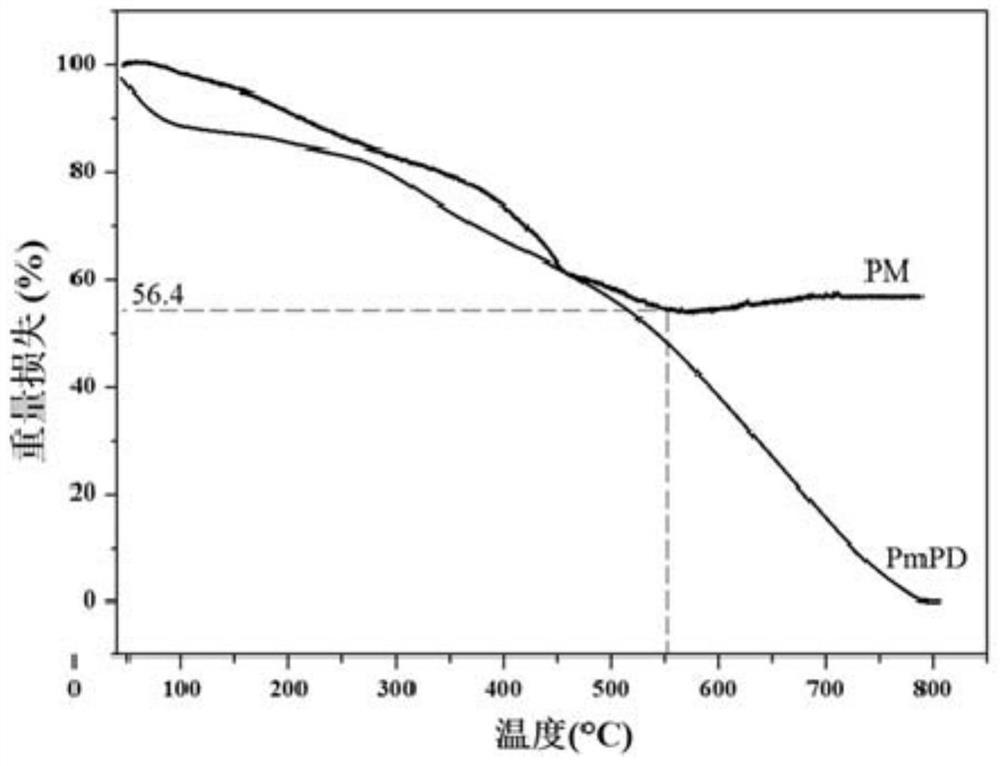

[0076] In this embodiment, the loading capacity of poly-m-phenylenediamine is 30% of the mass of manganese dioxide@poly-m-phenylenediamine composite material, and the loading capacity of manganese dioxide is 30% of the mass of manganese dioxide@poly-m-phenylenediamine composite material. 70%, the two are linked by Mn-O-C bonds.

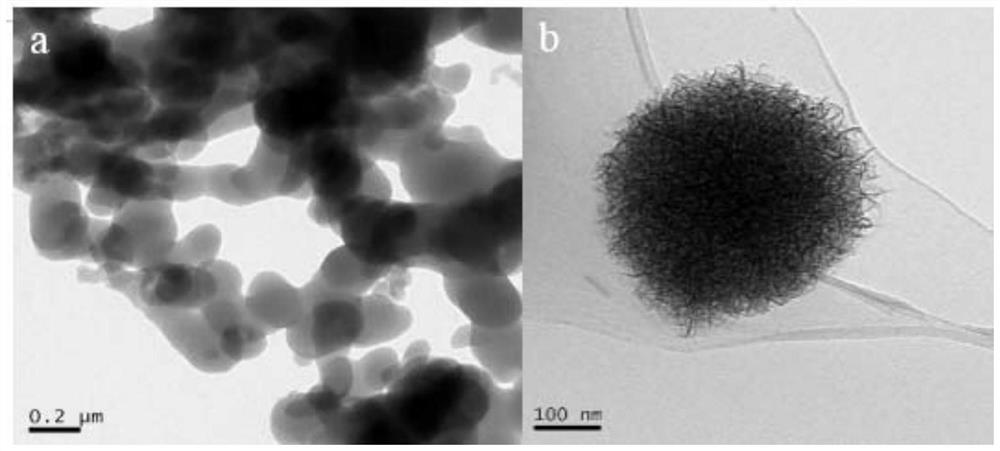

[0077] In this embodiment, the poly-m-phenylenediamine is spherical with smooth surface; the manganese dioxide@poly-m-phenylenediamine composite material is sea urchin with rough surface.

[0078] In this example, the manganese dioxide@poly-m-phenylenediamine composite material is dark brown powder.

[0079] A method for preparing the manganese dioxide@poly-m-phenylenediamin...

Embodiment 2

[0100] 1. The application of a manganese dioxide@poly-m-phenylenediamine composite material in the treatment of heavy metal wastewater, comprising the following steps:

[0101] Get the manganese dioxide@poly-m-phenylenediamine composite material (PM50, PM150, PM200, PM250) 5 mg each, respectively added to 20 mL of heavy metal wastewater with Pb concentration of 100 mg / L and pH of 5.3, placed in a constant temperature water bath at 25°C and 170 rpm for oscillating adsorption for 24 hours to complete the treatment of heavy metal wastewater.

[0102] 2. Get the comparative example PmPD and comparative example PM that are used in comparative example 3, the polym-phenylenediamine composite material (PmPD does not add NaOH) that does not add sodium hydroxide that makes in comparative example 4, embodiment Add 5 mg of each PM150 prepared in 1 to 20 mL of heavy metal wastewater with a Pb concentration of 50 mg / L and a pH of 5.3, and place it in a constant temperature water bath at 25°...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| clearance rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com