A kind of kaolinite-humic acid composite colloid preparation method for adsorbing acetaminophen

A technology of paracetamol and humic acid, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems that have not yet been discovered, and achieve convenient industrial production, high specific surface area, and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

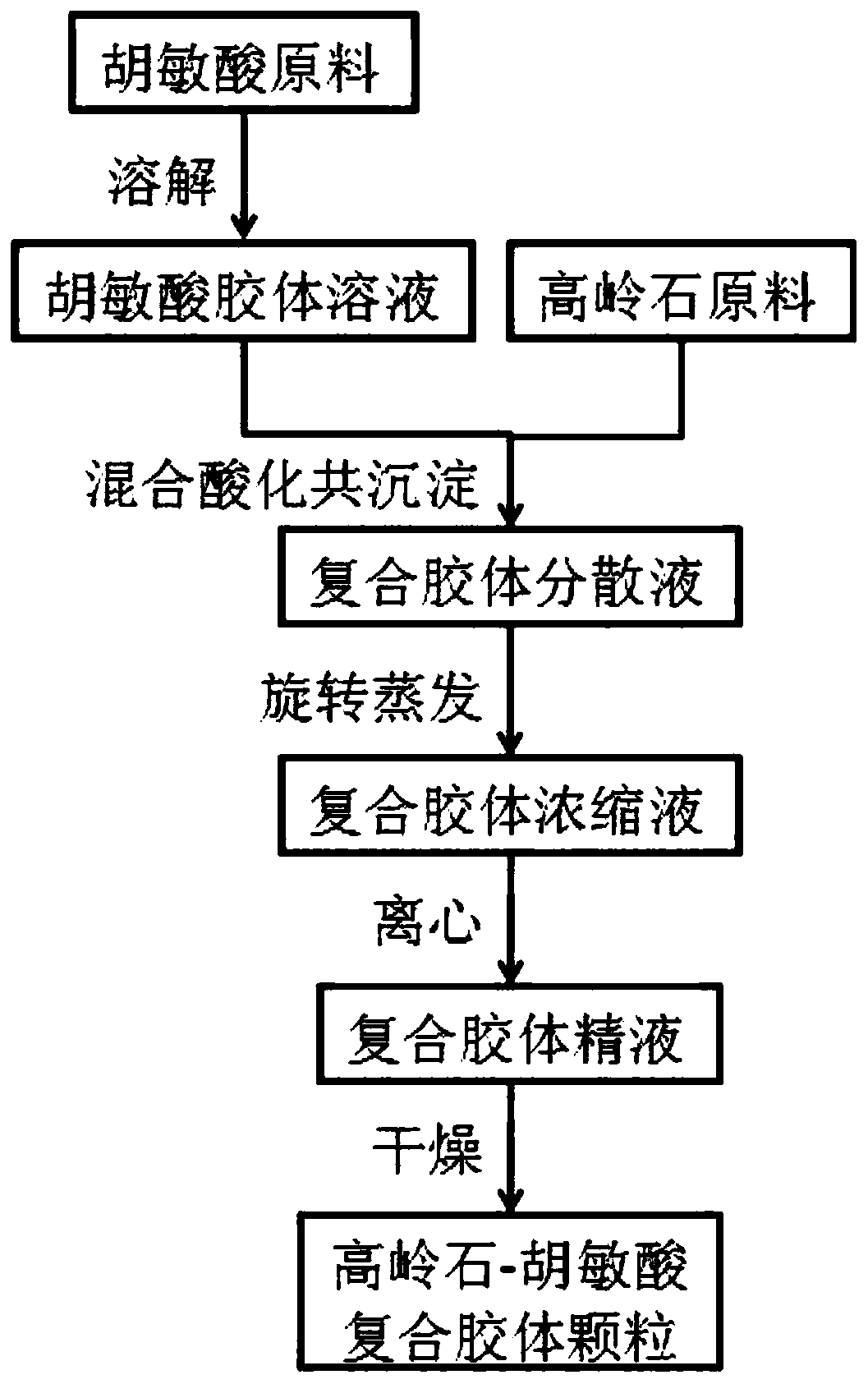

[0030] Such as figure 1 As shown, the method for preparing kaolinite-humic acid composite colloid in this embodiment specifically includes the following steps:

[0031] Step 1, dissolving: dissolve humic acid at a solid-to-liquid ratio (kg:m 3 ) at a ratio of 1:10 was dissolved in a sodium hydroxide solution with a concentration of 2% by mass to volume, magnetically stirred at a speed of 600 rpm at room temperature, stirred for 30 minutes until completely dissolved, and a colloidal solution of humic acid was obtained;

[0032] Step 2, mixed acidification co-precipitation: according to the ratio of kaolinite to humic acid mass ratio of 5:4, add kaolinite to the obtained humic acid colloid solution, and add concentrated hydrochloric acid to adjust the liquid phase pH to 1 , continuously stirred at 1100rpm during the adjustment process, and then stood in the dark at room temperature for 100min to obtain a composite colloidal dispersion;

[0033] Step 3, rotary evaporation: the ...

Embodiment 2

[0039] Such as figure 1 As shown, the method for preparing kaolinite-humic acid composite colloid in this embodiment specifically includes the following steps:

[0040] Step 1, dissolving: dissolve humic acid at a solid-to-liquid ratio (kg:m 3 ) in a ratio of 1:4 in a sodium hydroxide solution with a concentration of 6% by mass to volume, magnetically stirred at room temperature at 800 rpm, and stirred for 60 minutes until completely dissolved to obtain a colloidal solution of humic acid;

[0041] Step 2, mixed acidification co-precipitation: According to the mass ratio of kaolinite and humic acid of 1:1.25, kaolinite is added to the obtained humic acid colloid solution, and concentrated hydrochloric acid is added at the same time to adjust the liquid phase pH to 3, adjust Continue to stir at 1500rpm during the process, and then stand in the dark for 200min at room temperature to obtain a composite colloidal dispersion;

[0042] Step 3, rotary evaporation: the composite coll...

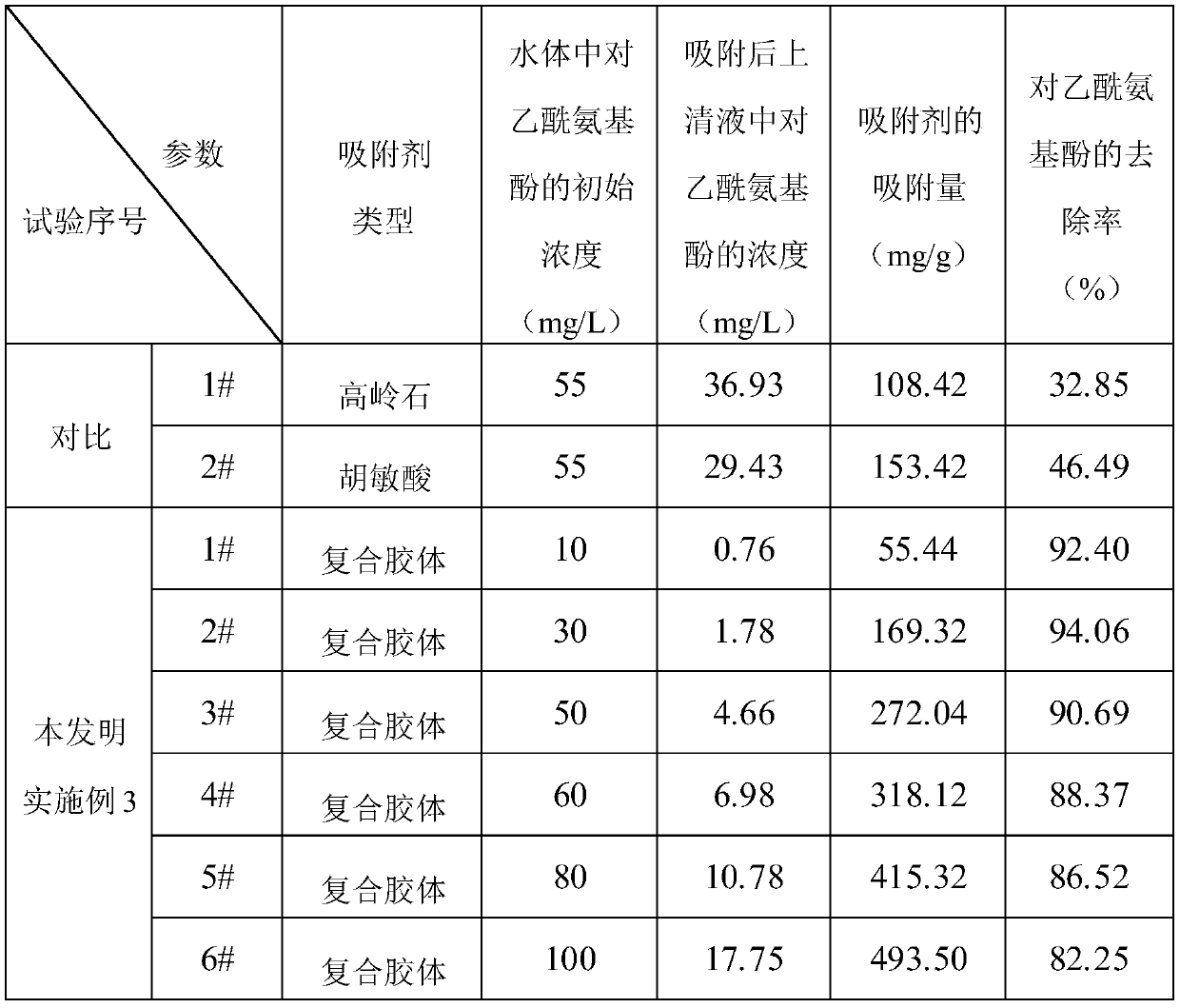

Embodiment 3

[0048] Such as figure 1 As shown, the method for preparing kaolinite-humic acid composite colloid in this embodiment specifically includes the following steps:

[0049] Step 1, dissolving: dissolve humic acid at a solid-to-liquid ratio (kg:m 3 Dissolve in a sodium hydroxide solution with a mass volume ratio of 4% in the ratio of )7:40, magnetically stir at 700 rpm at room temperature, stir for 45 minutes until completely dissolved, and obtain a colloidal solution of humic acid;

[0050] Step 2, mixed acidification co-precipitation: According to the mass ratio of kaolinite and humic acid of 1:0.88, kaolinite is added to the obtained humic acid colloid solution, and concentrated hydrochloric acid is added at the same time to adjust the pH of the liquid phase to 2. Continue to stir at 1300rpm during the process, and then stand in the dark for 150min at room temperature to obtain a composite colloidal dispersion;

[0051] Step 3, rotary evaporation: the composite colloidal dispe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com