Magnetic cross-linked chitosan as well as preparation method and application thereof

A technology for cross-linking chitosan, chitosan, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., can solve poor mechanical and electrical properties, application limitations, human health risks and other problems, to achieve good thermal stability, reduce processing costs, increase service life and cycle utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] One, prepare cross-linked chitosan;

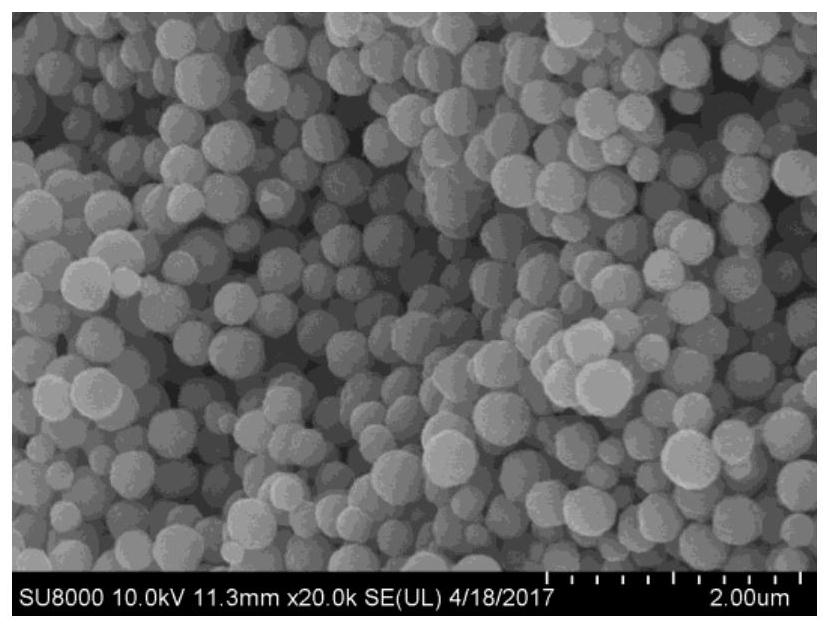

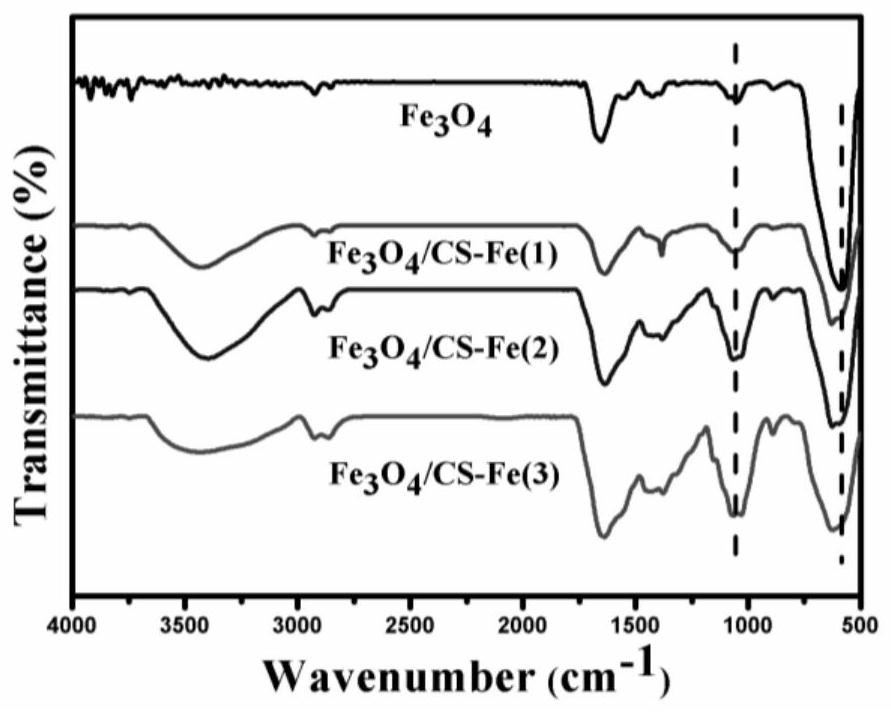

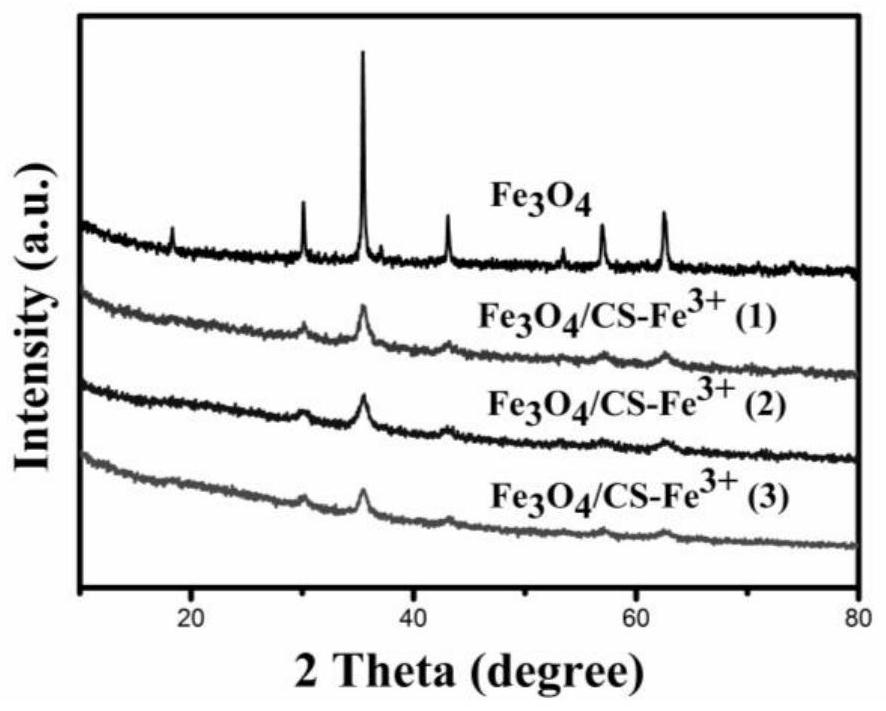

[0032] 10g chitosan (degree of deacetylation > 90%) was dissolved in 4% 550ml glutaraldehyde solution, stirred with a magnetic stirrer at a speed of 155r / min for 9 hours at room temperature, then filtered, and the filtrate was discarded; The obtained cross-linked chitosan was washed with ultrapure water for 3 times, and then put into a vacuum drying oven to dry for more than 12 hours to obtain dry cross-linked chitosan (CS).

[0033] 2. Preparation of magnetically cross-linked chitosan

[0034] 2.6g FeCl 3 ·6H 2 O was dissolved in 75ml of ethylene glycol, then 1.0g of powdered chitosan was added, and the mixture was stirred at room temperature for 8 hours, after stirring well, 3.0g of sodium acetate was added, mixed well, and the mixture was transferred to a 100mL polytetrafluoroethylene stainless steel high pressure Kettle, heated in a blast oven at 180°C for 7 hours. Subsequently, the autoclave was naturally cooled to room tem...

Embodiment 2

[0036] One, prepare cross-linked chitosan;

[0037] 10g chitosan (degree of deacetylation > 90%) was dissolved in 6% 450ml glutaraldehyde solution, stirred with a magnetic stirrer at a speed of 165r / min for 7 hours at room temperature, filtered then, and discarded the filtrate; The obtained cross-linked chitosan was washed with ultrapure water for 3 times, and then put into a vacuum drying oven to dry for more than 12 hours to obtain dry cross-linked chitosan (CS).

[0038] 2. Preparation of magnetically cross-linked chitosan

[0039] 2.6g FeCl 3 ·6H 2 O was dissolved in 85ml of ethylene glycol, then 1.0g of powdered chitosan was added, the mixture was stirred at room temperature for 8 hours, after stirring well, 3.4g of sodium acetate was added, mixed well, and the mixture was transferred to a 100mL polytetrafluoroethylene stainless steel high pressure Kettle, heated in a blast oven at 190°C for 5 hours. Subsequently, the autoclave was naturally cooled to room temperature...

Embodiment 3

[0041] One, prepare cross-linked chitosan;

[0042] 10g chitosan (degree of deacetylation > 90%) was dissolved in 5% 500ml glutaraldehyde solution, stirred with a magnetic stirrer at a speed of 160r / min for 8 hours at room temperature, then filtered, and the filtrate was discarded; The obtained cross-linked chitosan was washed with ultrapure water for 3 times, and then put into a vacuum drying oven to dry for more than 12 hours to obtain dry cross-linked chitosan (CS).

[0043] 2. Preparation of magnetically cross-linked chitosan

[0044] 2.6g FeCl 3 ·6H 2 O was dissolved in 80ml of ethylene glycol, then 3.0g of powdered chitosan was added, the mixture was stirred at room temperature for 8 hours, after stirring well, 3.2g of sodium acetate was added, mixed well, and the mixture was transferred to a 100mL polytetrafluoroethylene stainless steel high pressure Kettle, heated in a forced air oven at 185°C for 6 hours. Subsequently, the autoclave was naturally cooled to room te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com