Method for preparing ethyl lactate by biomass hydrothermal liquefaction

A hydrothermal liquefaction, ethyl lactate technology, applied in chemical instruments and methods, preparation of organic compounds, preparation of carboxylate, etc., can solve the problems of entrained toxic solvents, low product yield, poor product quality, etc. The effect of high rate, huge economic benefit and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

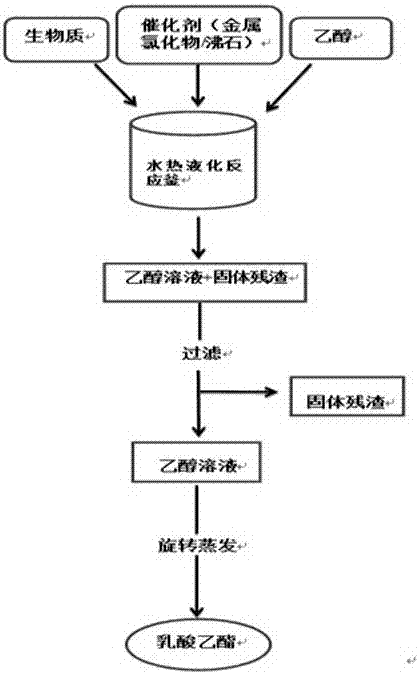

Method used

Image

Examples

Embodiment 1

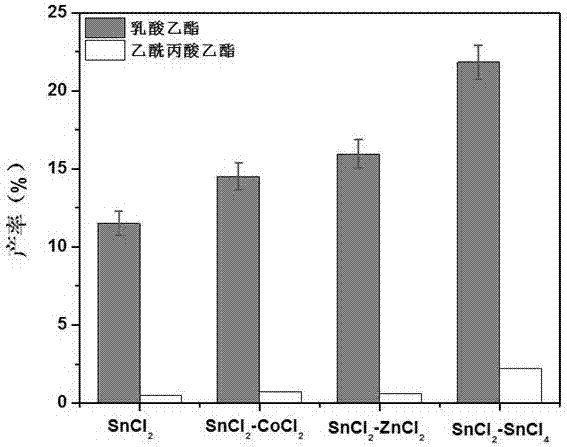

[0026] Put 0.5g rice straw and 20g ethanol in a 100mL stainless steel hydrothermal liquefaction reactor, add 0.056M catalyst SnCl 2 2H 2 O, and add 0.0458M metal chloride such as CoCl 2 , ZnCl 2 and SnCl 4 As a co-catalyst to increase the SnCl 2 2H 2 O catalytic activity. The mixture of rice straw, ethanol and catalyst was reacted at 220°C for 4 hours. Cool to room temperature after completion of the reaction, obtain the ethanol solution after filtration and analyze the content of ethyl lactate wherein by GC-MS, SnCl 2 and SnCl 4 The yield of ethyl lactate was the highest under the action of co-catalysis, about 22%.

Embodiment 2

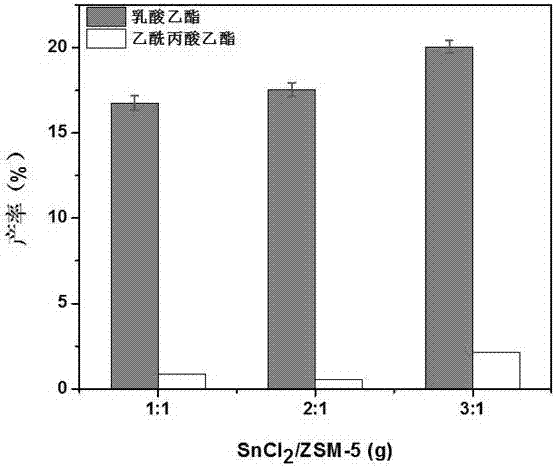

[0028] Put 0.5g rice straw and 20g ethanol in a 100mL stainless steel hydrothermal liquefaction reactor, add catalyst SnCl 2 2H 2 O, and adding zeolite ZSM-5 as a co-catalyst to increase the SnCl 2 2H 2 O catalytic activity. SnCl 2 2H 2 The mass ratios of O and ZSM-5 are 1:1, 2:1 and 3:1. The mixture of rice straw, ethanol and catalyst was reacted at 220°C for 4 hours. Cool to room temperature after completion of the reaction, obtain the ethanol solution after filtration and analyze the content of ethyl lactate wherein by GC-MS, SnCl 2 When the mass ratio of ZSM-5 is 3:1, the yield of ethyl lactate is the highest, about 20%.

Embodiment 3

[0030] Put 0.5g rice straw and 20g ethanol in a 100mL stainless steel hydrothermal liquefaction reactor, add catalyst SnCl 2 2H 2 O, and adding zeolite ZSM-5 as a cocatalyst. The Si / Al ratio of ZSM-5 is 100, 150 and 200, ZSM-5 and SnCl 2 2H 2 The mass ratio of O is 3:1. The mixture of rice straw, ethanol and catalyst was reacted at 220°C for 4 hours. Cool to room temperature after completion of the reaction, obtain ethanol solution after filtration and analyze the ethyl lactate content wherein by GC-MS, the higher the Si / Al ratio, the higher the productive rate of ethyl lactate, when the Si / Al ratio is 200, the ethyl lactate The yield of ester is about 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com