Real-time dynamic separation and continuous reaction system for biodiesel transesterification and application of system

A real-time dynamic, biodiesel technology, applied in the fields of biofuels, fatty acid esterification, chemical/physical/physical-chemical processes, etc., to achieve the effect of improving reaction efficiency, conversion rate, and conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

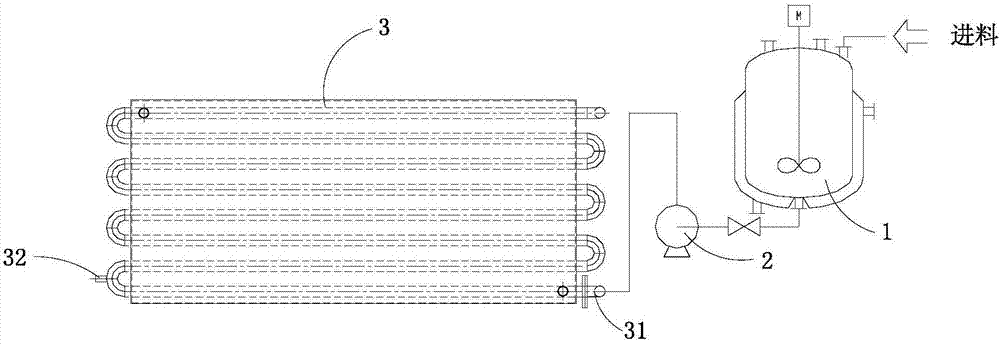

[0040] The working process of the biodiesel transesterification real-time dynamic separation continuous reaction system is as follows:

[0041] (1) Mix anhydrous methanol and KOH and then mix them with rapeseed oil and add them to the stirring mixing tank for thorough mixing, wherein the molar ratio of anhydrous methanol to rapeseed oil is 6:1, and the mass ratio of KOH to rapeseed oil is 0.1;

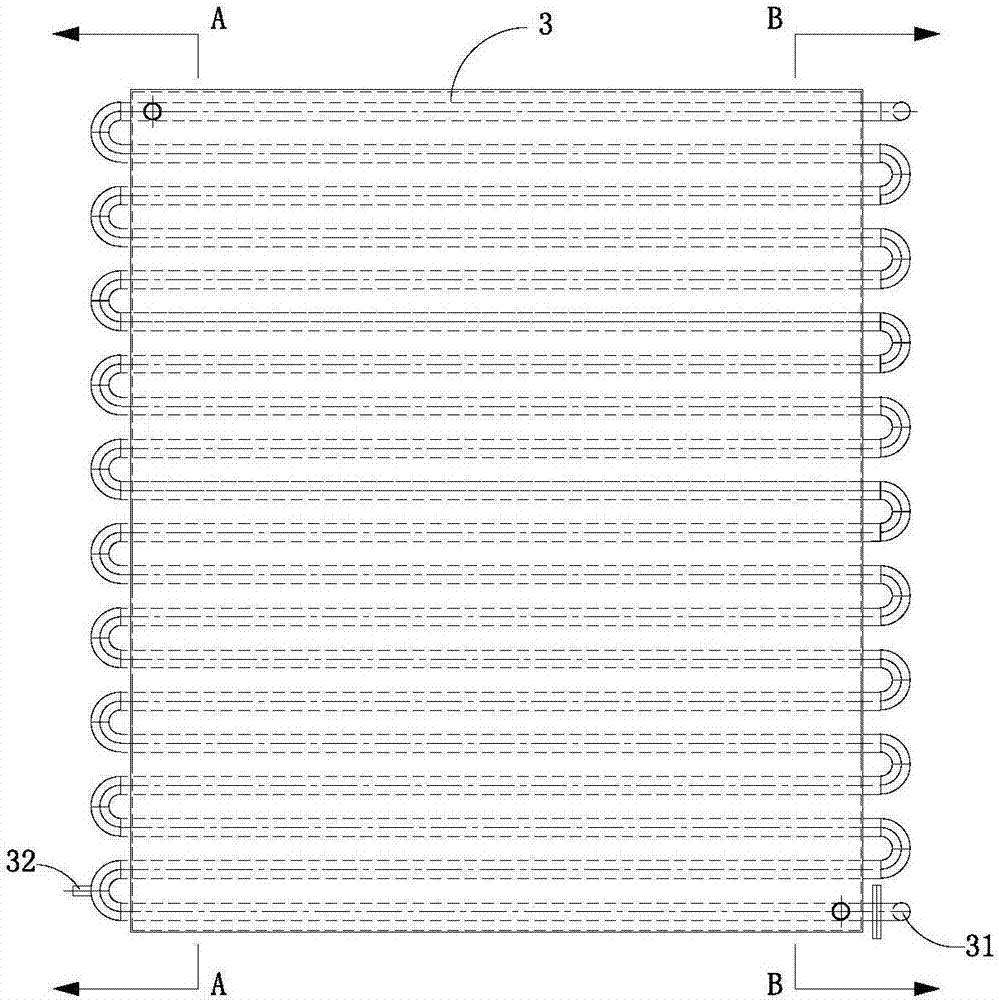

[0042] (2) The above-mentioned mixture is input into a tubular plug flow reactor with a temperature of 67°C at a flow rate of 0.77 m / s through a material pump;

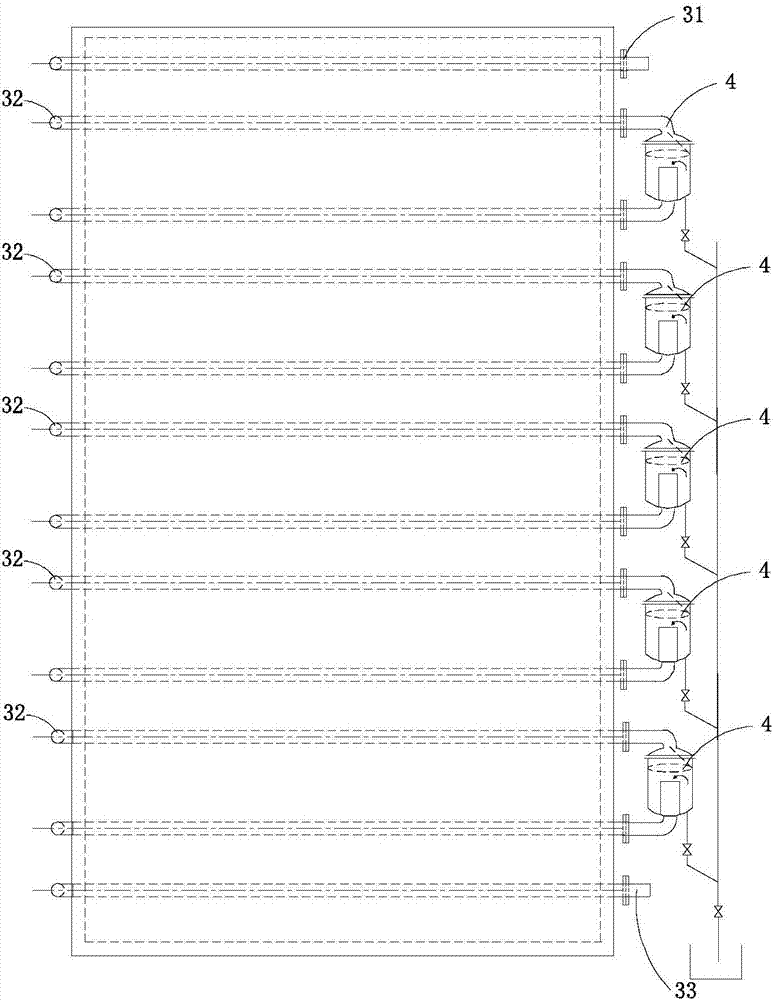

[0043] (3) Under the action of KOH, anhydrous methanol and rapeseed oil gradually undergo transesterification reaction in the process of propulsion in the tubular plug flow reactor to generate biodiesel and glycerol. Settle and discharge from the outlet of glycerin; unreacted oil, methanol, biodiesel and lye, after flowing through the real-time dynamic separation device of glycerin, enter the next layer of plug flow reactor t...

Embodiment 2

[0047] Same as Example 1, the difference is:

[0048] The reaction temperature in the plug flow reactor is 65°C, the liquid alkaline catalyst is NaOH, the raw material oil is soybean oil, the weight ratio of NaOH to soybean oil is 0.3, and the molar ratio of anhydrous methanol to soybean oil is 6:1.

[0049] It has been determined that the conversion rate of the product is about 99.5% under this condition.

Embodiment 3

[0051] Same as Example 1, the difference is:

[0052] The reaction temperature in the plug flow reactor is 65°C, the liquid alkaline catalyst is KOH, the raw material oil is pistachio oil, the weight ratio of KOH to pistachio oil is 0.2, and the molar ratio of anhydrous methanol to pistachio oil is 6:1 .

[0053] It has been determined that the conversion rate of the product is about 99.3% under this condition.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com