Colored toner prepared by adopting mini-emulsion polymerization and ball-milling compounding and method

A technology of color toner and polyethylene wax emulsion, which is applied in instruments, developers, optics, etc., can solve the problems of easy leakage, weak combination of wax and resin, etc., and achieve simple process, narrow distribution, and uniform charge distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

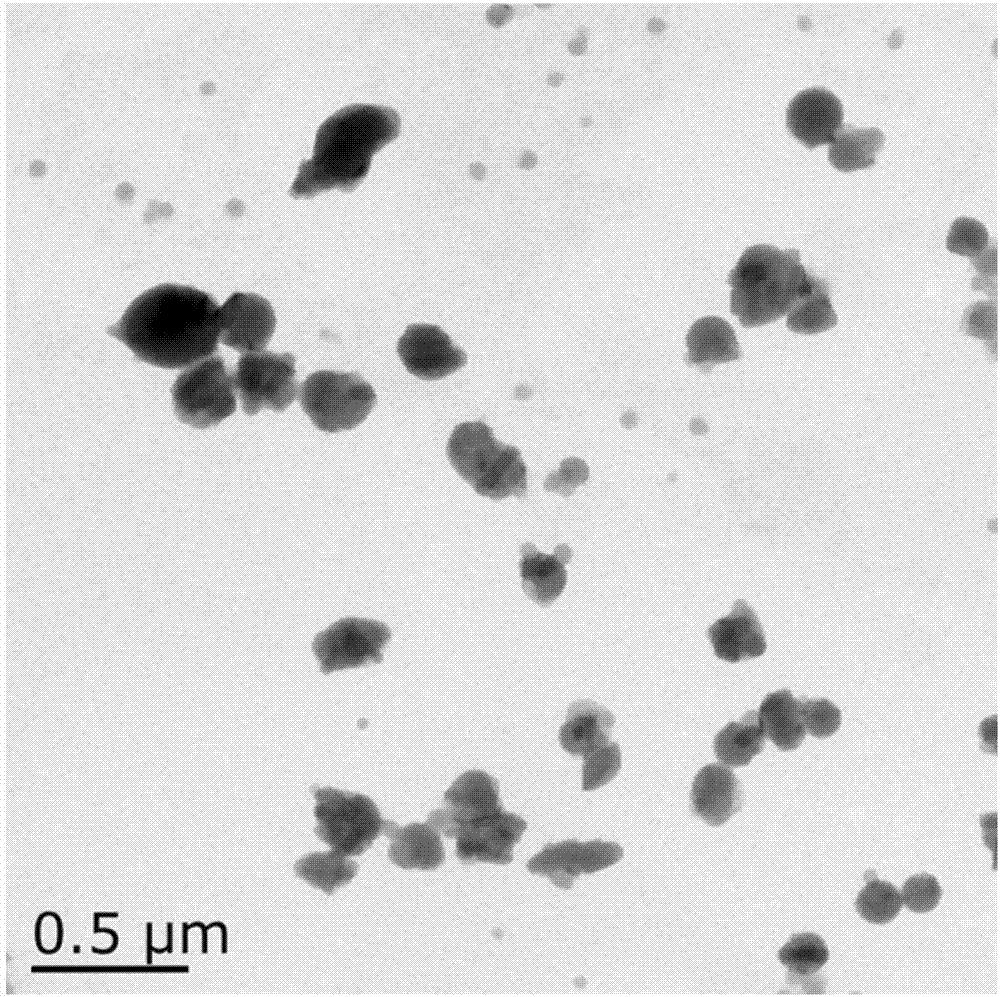

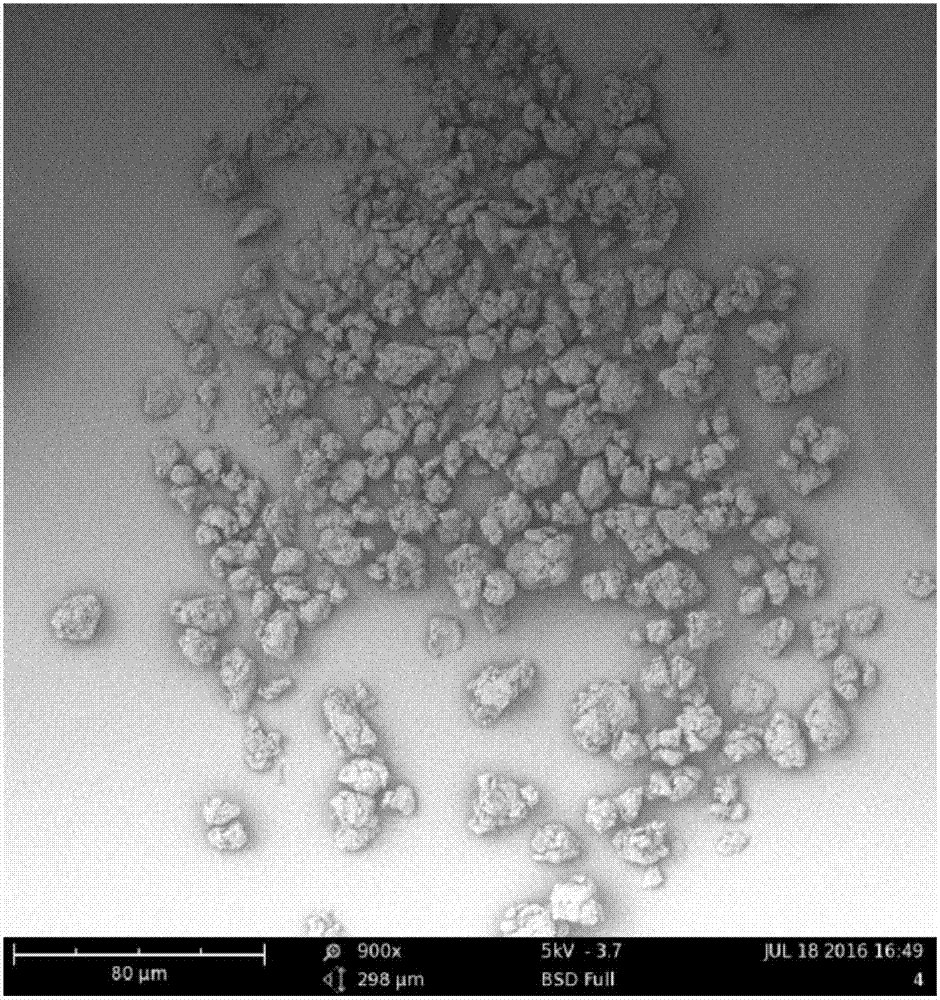

Image

Examples

Embodiment 1

[0045] (1) Take 0.4 parts of organic pigment PY12, 2 parts of anionic polyethylene wax emulsion WE-7, and 0.3 parts of TX-100 into a beaker, and add 40 parts of deionized water, ultrasonic for 5 minutes, so that the pigment and polyethylene wax are evenly dispersed , and then transfer the mixed solution in the beaker to a ball mill tank filled with zirconia microspheres with a particle size of 1.2mm~1.6mm, and disperse for 8 hours by ball milling, wherein the mass ratio of zirconia microspheres to organic pigments is 100:1, ball mill speed is 580r / min;

[0046](2) Weigh 8 parts of styrene and 2 parts of butyl acrylate in a beaker, add 50 parts of deionized water, ultrasonically disperse for 10 minutes, add the stable and uniform dispersion obtained after ball milling in (1), and mix Continue to sonicate for 40 minutes, transfer the mixed solution after sonication into a four-necked flask heated by a water bath, dissolve 0.2 parts of the initiator KPS in 15 parts of deionized w...

Embodiment 2

[0050] (1) Add 0.8 parts of organic pigment PB15:3, 3 parts of cationic polyethylene wax emulsion WX-448, and 0.4 parts of OP-10 into a beaker, add 35 parts of deionized water, and ultrasonicate for 10 minutes to make the pigment and polyethylene wax Disperse evenly. Then the mixed solution in the beaker is transferred to a ball mill jar filled with zirconia microspheres with a particle size of 1.2 mm to 1.6 mm, and the ball mill is dispersed for 6 hours, wherein the mass ratio of zirconia microspheres to organic pigments is 50 : 1, the ball mill rotating speed is 580r / min;

[0051] (2) Weigh 7.5 parts of styrene, 2.5 parts of butyl acrylate, add 60 parts of deionized water, stir and disperse for 20 minutes while ultrasonicating, add the stable and uniform dispersion obtained after ball milling in (1), and mix Continue to sonicate for 30 minutes, transfer the mixed solution after sonication into a four-necked flask heated by a water bath, dissolve 0.3 parts of the initiator K...

Embodiment 3

[0055] (1) Add 0.2 parts of organic pigment PR122, 1 part of anionic polyethylene wax emulsion WE-1, and 0.2 parts of TX-100 into a beaker, add 40 parts of deionized water, and ultrasonically 8 minutes to disperse the pigment and polyethylene wax evenly , and then transfer the mixed solution in the beaker to a ball mill jar filled with zirconia microspheres with a particle size of 1.2 mm to 1.6 mm, and ball mill to disperse for 4 hours. Wherein, the mass ratio of zirconia microspheres and organic pigments is 150:1, and the ball mill rotating speed is 580r / min;

[0056] (2) Weigh 8.5 parts of styrene and 1.5 parts of butyl acrylate in a beaker, add 50 parts of deionized water, and ultrasonically disperse for 15 minutes, add the stable and uniform dispersion obtained after ball milling in (1), and mix Continue the ultrasonic time for 50 minutes, transfer the ultrasonic mixed solution into a four-necked flask heated by a water bath, dissolve 0.1 part of initiator KPS in 15 parts ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com