Preparation method of high-concentration low-temperature stable liquid colorant

A low-temperature stable, high-concentration technology, used in fertilizer mixtures, organic dyes, fertilization devices, etc., can solve the problems of poor storage and transportation stability of liquid colorants, easy crystallization, flocculation, low coloring strength, etc., to achieve uniform coloring effect, Rich color compatibility, good low temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

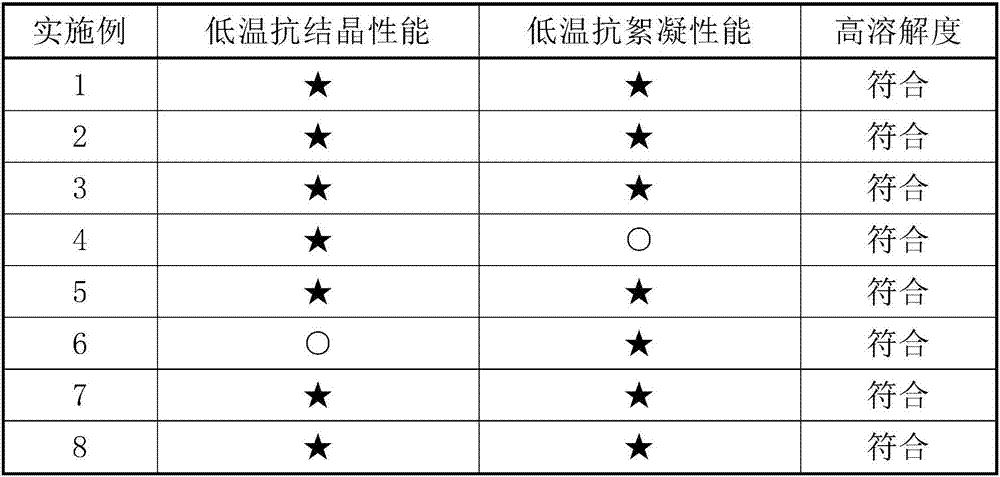

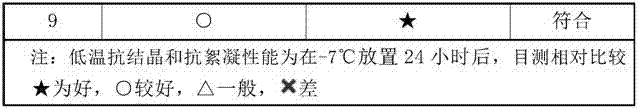

Examples

Embodiment 1

[0023] Preparation of Yellow High Concentration Low Temperature Stable Liquid Colorant (1)

[0024] In a 1200L preparation pot, add 800L of Acid Yellow 23# pigment coupling solution, start stirring, heat up to 55°C and add 3.5kg of hydrochloric acid in a liquid state, adjust the pH of the solution to 4.2, keep stirring for 30 minutes, add 2kg of liquid caustic soda, and adjust the pH of the solution to 6.3 . Then add 16kg of thiobisethanol at room temperature; add 40kg of ammonium lignosulfonate as a dispersant and stir quickly evenly.

Embodiment 2

[0026] Preparation of Yellow High Concentration and Low Temperature Stable Liquid Colorant (2)

[0027] In a 1200L preparation pot, add 500L of edible yellow 5# pigment coupling solution and 300L of edible yellow 6# pigment coupling solution, start stirring, heat up to 70°C, add 3.4kg of 30% hydrochloric acid in a liquid state, adjust the pH of the solution to 4.2, and keep stirring for 30 minutes Then add 2kg of liquid caustic soda to adjust the pH of the solution to 7.0. Then add 34kg of glycerol and 30kg of diethylene glycol ether at 50°C; add 80kg of lignosulfonate sodium salt as a dispersant and stir evenly; , for packaging.

Embodiment 3

[0029] Preparation of Yellow High Concentration and Low Temperature Stable Liquid Colorant (3)

[0030] In a 1200L preparation pot, add 560L of basic yellow 11# pigment coupling solution and 240L of basic yellow 13# pigment coupling solution, start stirring, heat up to 48°C, add 3.4kg of 31% hydrochloric acid in liquid form, adjust the pH of the solution to 4.3, keep stirring After 30 minutes, 2 kg of liquid caustic soda was added to adjust the pH of the solution to 6.5. Then add 30kg of propylene glycol and 30kg of diethylene glycol ether at 55°C; add 80kg of lignosulfonate sodium salt as a dispersant and stir quickly evenly, and after the product has passed the standardization and quality control analysis and test for low-temperature anti-crystallization and anti-flocculation performance, carry out Package.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com