Manufacturing method for thin-walled-round-table-shaped lower heat shield parts of electron gun of klystron

A manufacturing method, frustum-shaped technology, applied in klystrons, electrode system manufacturing, electron tubes with speed/density modulation electron flow, etc., can solve the problem of long trial mold adjustment time, high part manufacturing cost, long trial production cycle, etc. problems, to achieve the effect of improving yield, avoiding multiple stamping extensions, and reducing processing difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0044] The traditional stamping and drawing mechanical method is relatively easy for thick-walled parts with a wall thickness of 1-3mm. Due to the thick material, the parts are easy to form after stamping. For thin-walled parts with a wall thickness of 0.05-0.20mm, some shapes It is easy to spring back and deform after stamping, and it is easy to break the material due to the thinness of the material during the stamping process, that is, the traditional stamping and drawing mechanical method has large material loss and low yield in the process of manufacturing thin-walled parts.

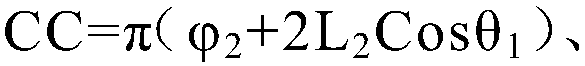

[0045] Therefore, in order to realize the forming of thin-walled parts, the present invention adopts segmental forming of complex, multiple stamping and extension parts. The thin-walled frustum-shaped lower heat shield part of the klystron electron gun inclu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com