Efficient flame-retardant environment-friendly polyurethane flexible foam plastic for interior part of passenger car and preparation method of efficient flame-retardant environment-friendly polyurethane flexible foam plastic

A flexible foam and polyurethane technology, which is applied in the field of flame-retardant polyurethane flexible foam, can solve the problems of interior fabric composites that do not meet the requirements, and achieve the effects of good resilience, soft hand feeling and high peel strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

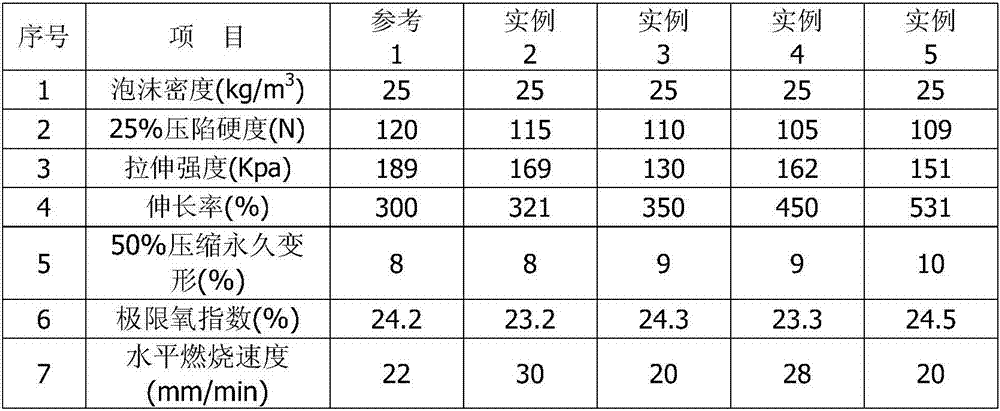

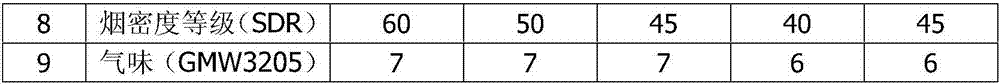

[0026] The present invention is further illustrated by the following examples, but the present invention is not limited to the following examples. Unless otherwise specified, all amounts given in "parts" and "percentage" should be understood as weight. The following materials were used to produce the polyurethane foams of the examples:

[0027] Table 1 Brief Introduction of Polyurethane Raw Materials

[0028] serial number

Remark

1

Adipic acid polyester polyol, the hydroxyl value is 42mgKOH / g;

2

Structural Flame Retardant Polyether Polyol B

Phosphorus-containing flame-retardant polyether polyol, hydroxyl value 56mgKOH / g, functionality 3;

3

Toluene diisocyanate (TDI-80), NCO group content is about 48.2%

4

Catalyst A

Low Odor Triethylenediamine (33% Propylene Glycol Solution)

5

Catalyst B

6

Foam Stabilizer A

Silicone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com