Combined type coal tar recycling equipment and coal tar recycling method thereof

A coal tar, combined technology, used in the removal of tar by water, the oil industry, the removal of gas pollutants, etc., can solve the problems of hindering electrode discharge, occupying a large area, and difficult to recycle and reuse, and achieve high efficiency. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embodiments of the present invention, not all of them.

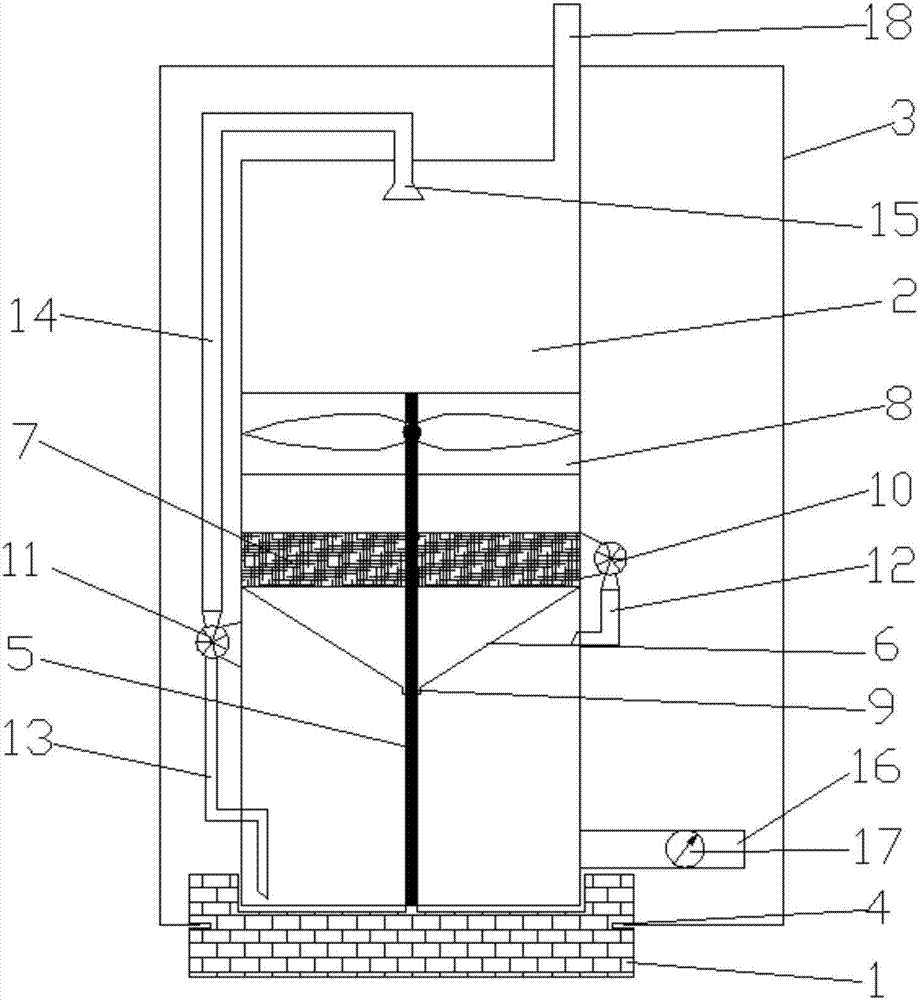

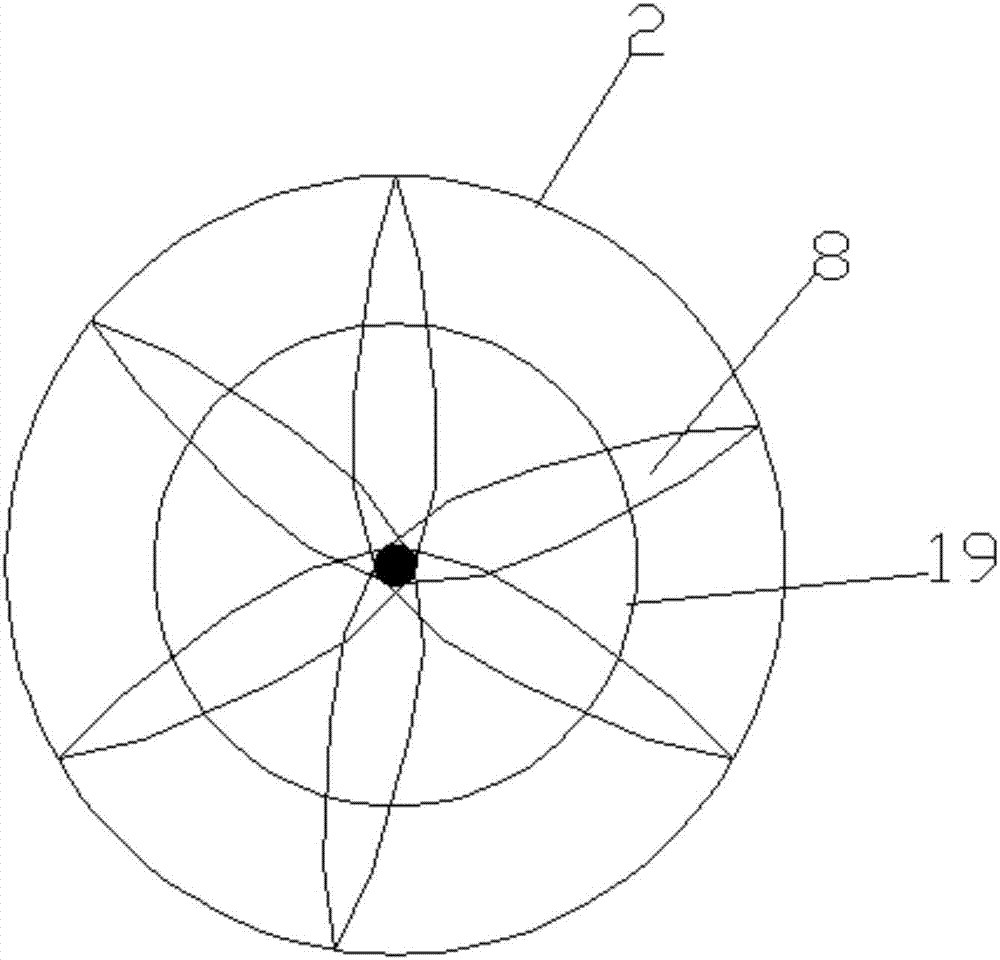

[0031] refer to Figure 1-2, a combined coal tar recovery equipment and coal tar recovery method thereof, the combined coal tar recovery equipment includes a base 1, a rotating cylinder 2 and a protective cover 3, the upper surface of the base 1 is grooved, the The bottom of the base 1 is fixed on the ground or the factory platform, the protective cover 3 is placed above the base 1, the side wall of the base 1 is provided with a circular card slot 4, and the opening of the protective cover 3 passes through the card The groove 4 is clamped on the side wall of the base 1, the rotating cylinder 2 is placed on the protective cover 3, the rotating cylinder 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com