Liquid palladium cleaning solution and method for removing metal impurities from liquid palladium

A technology of metal impurities and cleaning solution, which is applied in the field of palladium water cleaning solution and the removal of metal impurities in palladium water, which can solve problems such as pitting, missing plating of electroplating products, copper pollution, etc., and achieve the effect of avoiding copper pollution and being easy to handle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

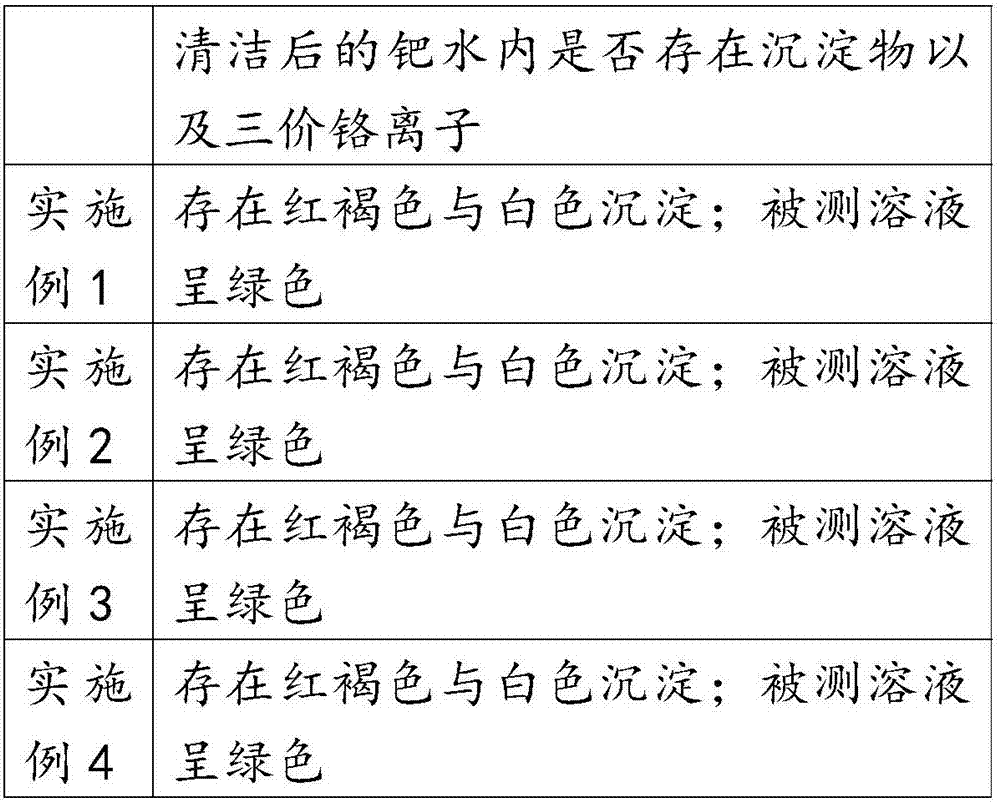

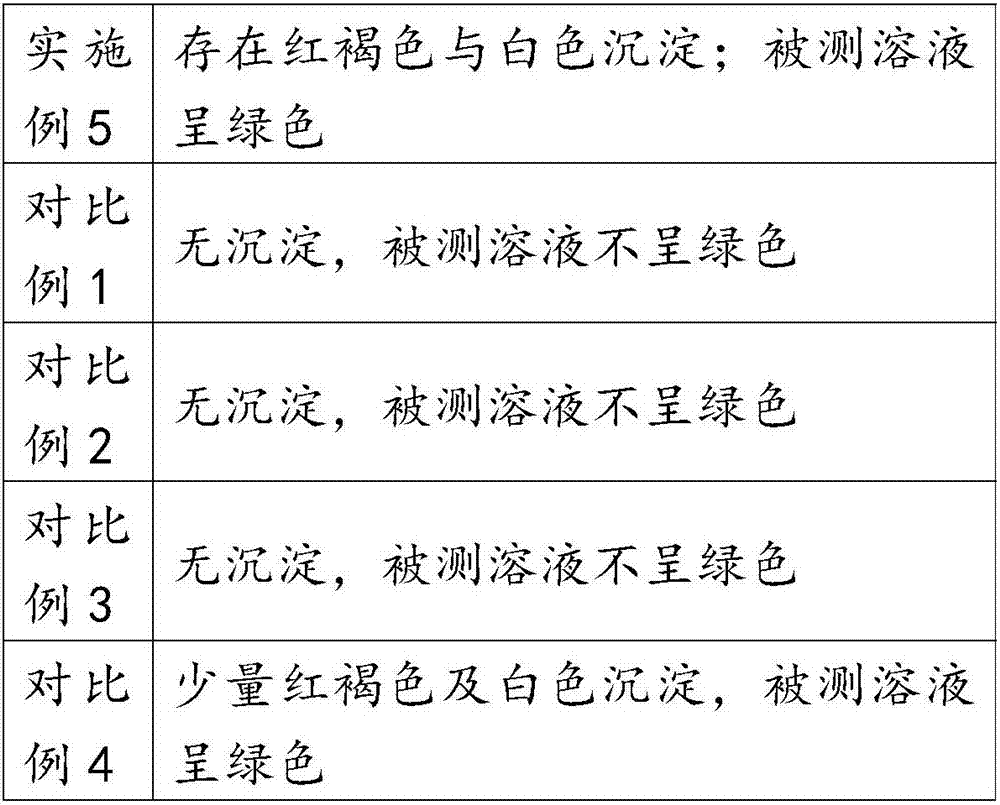

Examples

Embodiment 1

[0018] 1. Preparation of palladium water cleaning solution

[0019] Dissolve acid in water, then add soluble palladium salt, add soluble stannous salt after dissolving to obtain palladium water cleaning solution a1, wherein acid is hydrochloric acid, the content of hydrochloric acid is 320g / L, soluble palladium salt is palladium chloride, chloride The content of palladium is 4.0×10 -4 g / L, the soluble stannous salt is stannous chloride, and the content of stannous chloride is 10g / L.

[0020] 2. The plastic electroplating process includes the following steps:

[0021] (1) Substrate pre-treatment two-color plastic (PC and ABS, ABS injection molding for electroless plating area, PC injection molding for non-chemical plating area): Put the two-color plastic into the degreasing liquid, which includes the following components: sodium hydroxide 1mol / L, 1mol / L sodium carbonate, and 0.1mol / L sodium dodecylsulfonate, soak for 5 minutes at 50°C, take it out and wash it with tap water. ...

Embodiment 2

[0030] Prepare palladium water cleaning solution a2 according to the method of Example 1. The difference is that the soluble palladium salt in the palladium water cleaning solution a2 is palladium sulfate, and the content of palladium sulfate is 4.2×10 -4 g / L, the acid is sulfuric acid, the content of sulfuric acid is 290g / L and the soluble stannous salt is stannous chloride, and the content of stannous chloride is 5g / L.

[0031] Clean the palladium water and prepare the plated part b2 according to the method of Example 1, the difference is that when the palladium water cleaning solution is added to the palladium water, the temperature rises to 55 ° C, and the soaking time is 5 hours under the condition of heat preservation.

Embodiment 3

[0033] Prepare palladium water cleaning solution a3 according to the method of Example 1. The difference is that the soluble palladium salt in palladium water cleaning solution a3 is palladium chloride, and the content of palladium chloride is 4.5×10 -4 g / L, the acid is hydrochloric acid, the content of hydrochloric acid is 260g / L and the soluble stannous salt is stannous chloride, and the content of stannous chloride is 0.5g / L.

[0034] Clean the palladium water and prepare the plated part b3 according to the method of Example 1, the difference is that the temperature rises to 56°C when the palladium water cleaning solution is added to the palladium water, and the soaking time is 5h under the condition of heat preservation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com